Three-wire system high-power LED driver

A LED driver and high-power technology, which is applied in semiconductor devices of light-emitting elements, lighting devices, light sources, etc., can solve problems such as weakening impact, and achieve the effect of avoiding current impact and avoiding current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

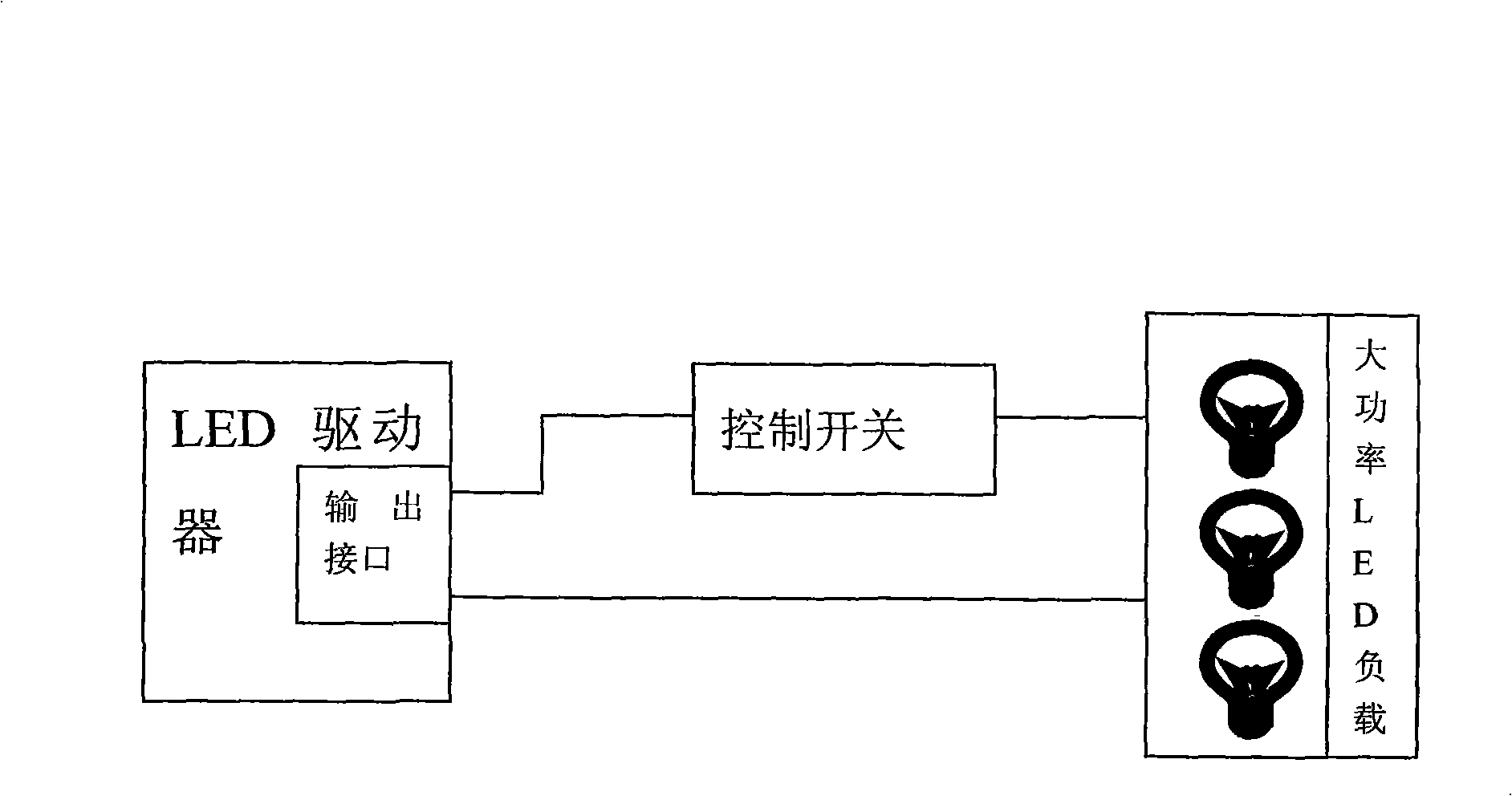

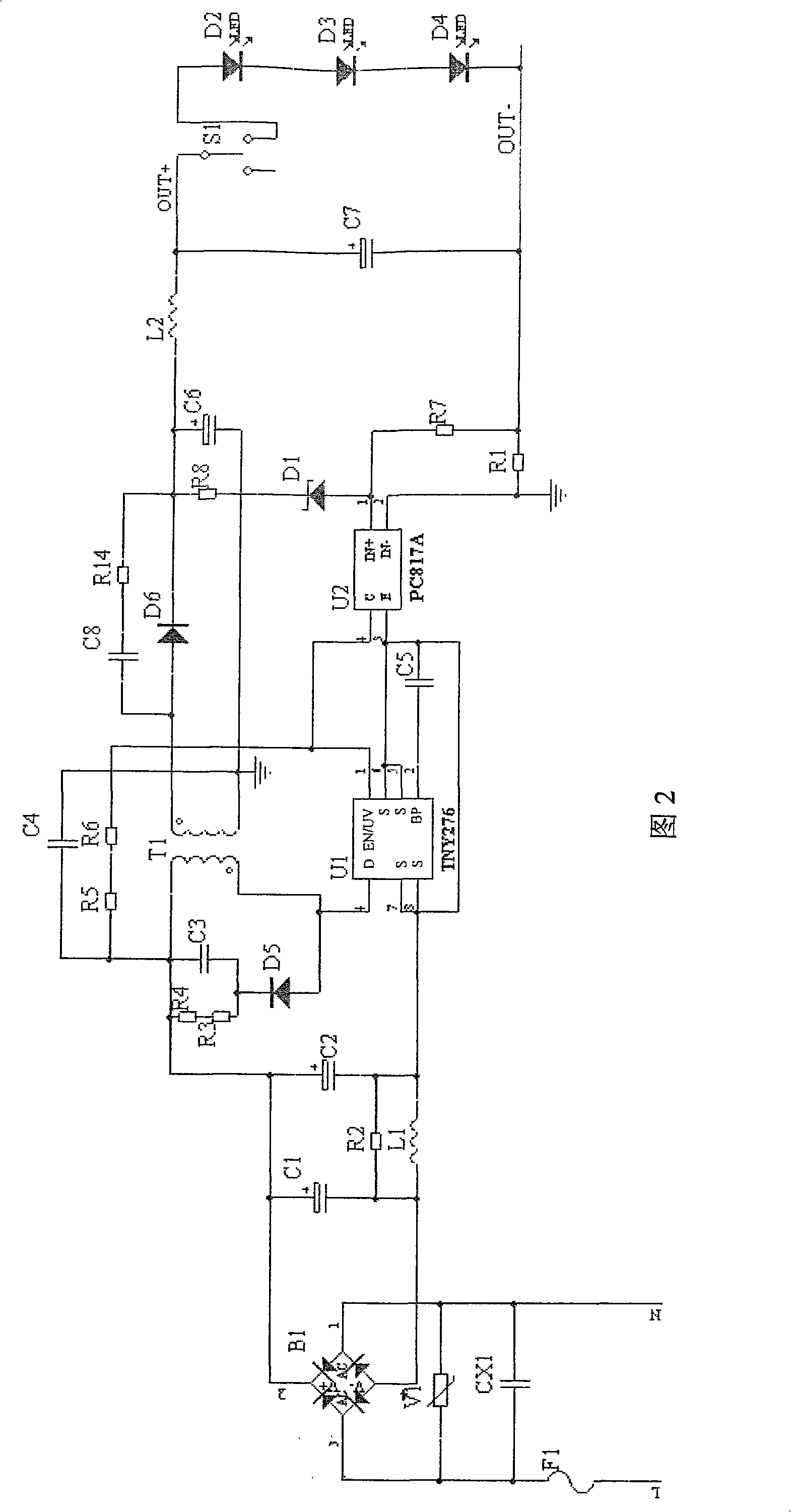

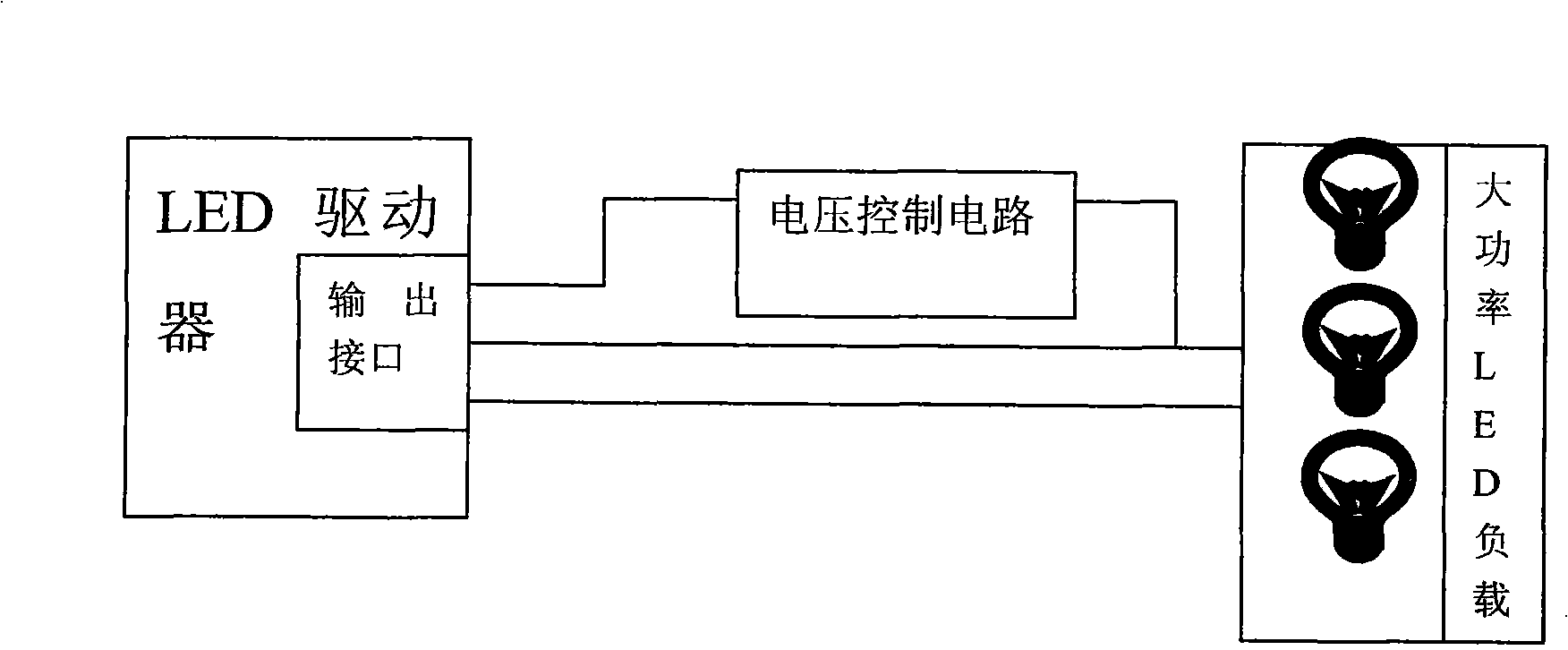

[0020] see image 3 The "voltage control circuit" of the three-wire high-power LED driver of the present invention is a switch circuit, which can form a closed loop with one of the original two output lines, and can control the size of the voltage output. The "output interface" is changed from the original "two-core wire" to "three-core wire". When the light source is turned on, the closed loop is tried to be disconnected, and the output voltage starts to climb upwards from the initial 2V, thus avoiding the impact of the driver on the LED (the impact occurs when the impact is converted from a higher voltage to a lower voltage). When the output current of the driver reaches the set value, the output voltage of the driver reaches a steady state.

[0021] see image 3 ~4. The three-wire high-power LED driver of the present invention has three output lines, which are respectively "output positive terminal", "output negative terminal" and "signal control line", "S1" is the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com