Sprayer capable of preventing abrasive on grinder table from aggregating and use method thereof

A technology of grinding machine table and water spraying device, which is applied in the direction of grinding device, grinding machine tool, grinding/polishing safety device, etc., can solve problems such as grinding wafer defects, and achieve the effect of ensuring grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The water spray device for preventing the aggregation of the abrasive on the grinder table and its use of the present invention will be further described in detail below.

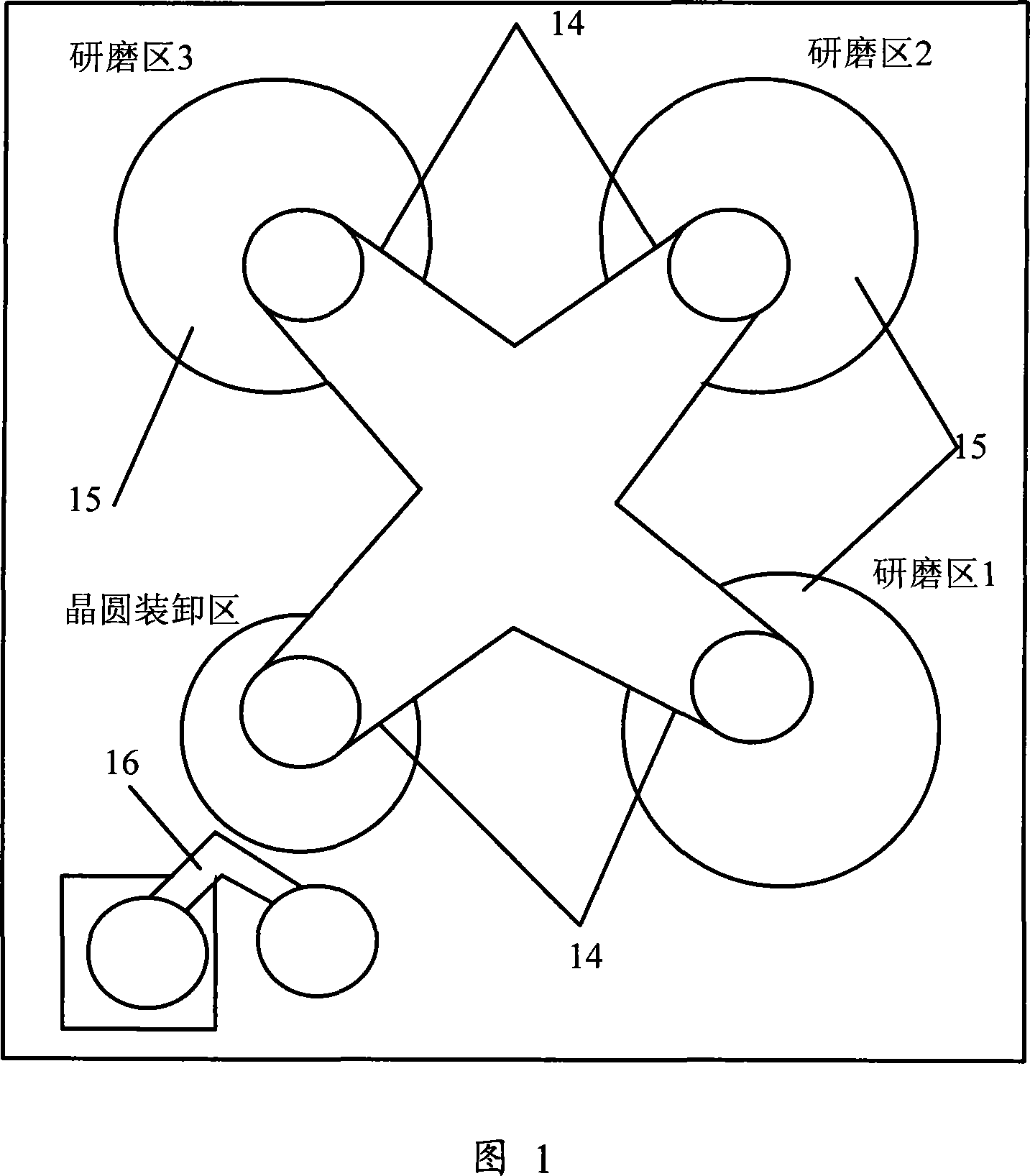

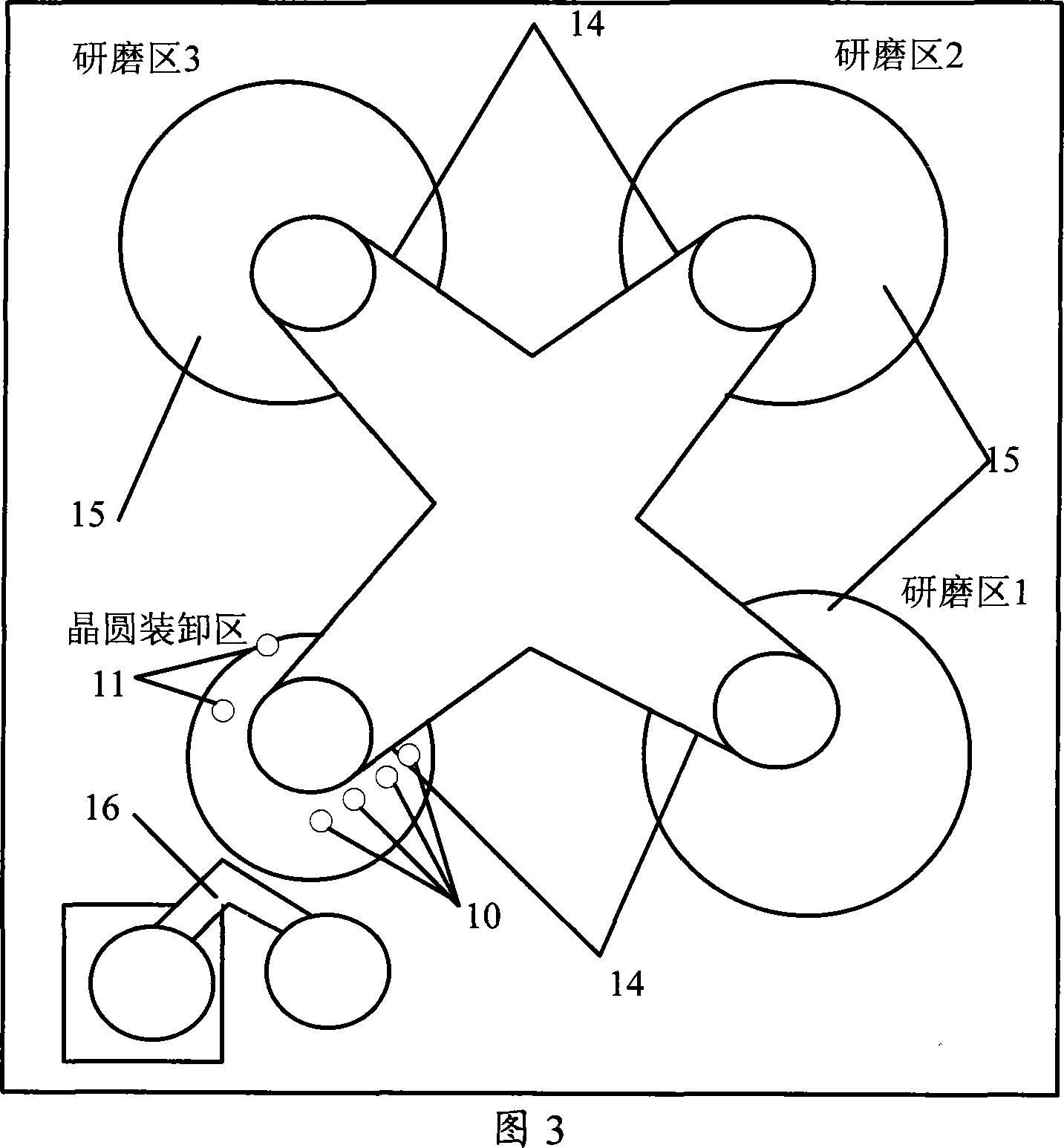

[0017] The grinder table generally includes several grinding areas and a wafer loading and unloading area, a moisturizing device with several interfaces and a grinder table control unit. Each grinding area and wafer area will have a robot head, and each grinding area will be equipped with a polishing pad.

[0018] When the grinding machine is working, the control unit can automatically control the opening and closing of the moisturizing device with several interfaces. The moisturizing device is communicated with the deionized water source. When the grinding head is loaded with wafers or after the wafer is unloaded, the control unit will automatically open the moisturizing device to clean and moisturize the grinding head under the mechanical head with deionized water.

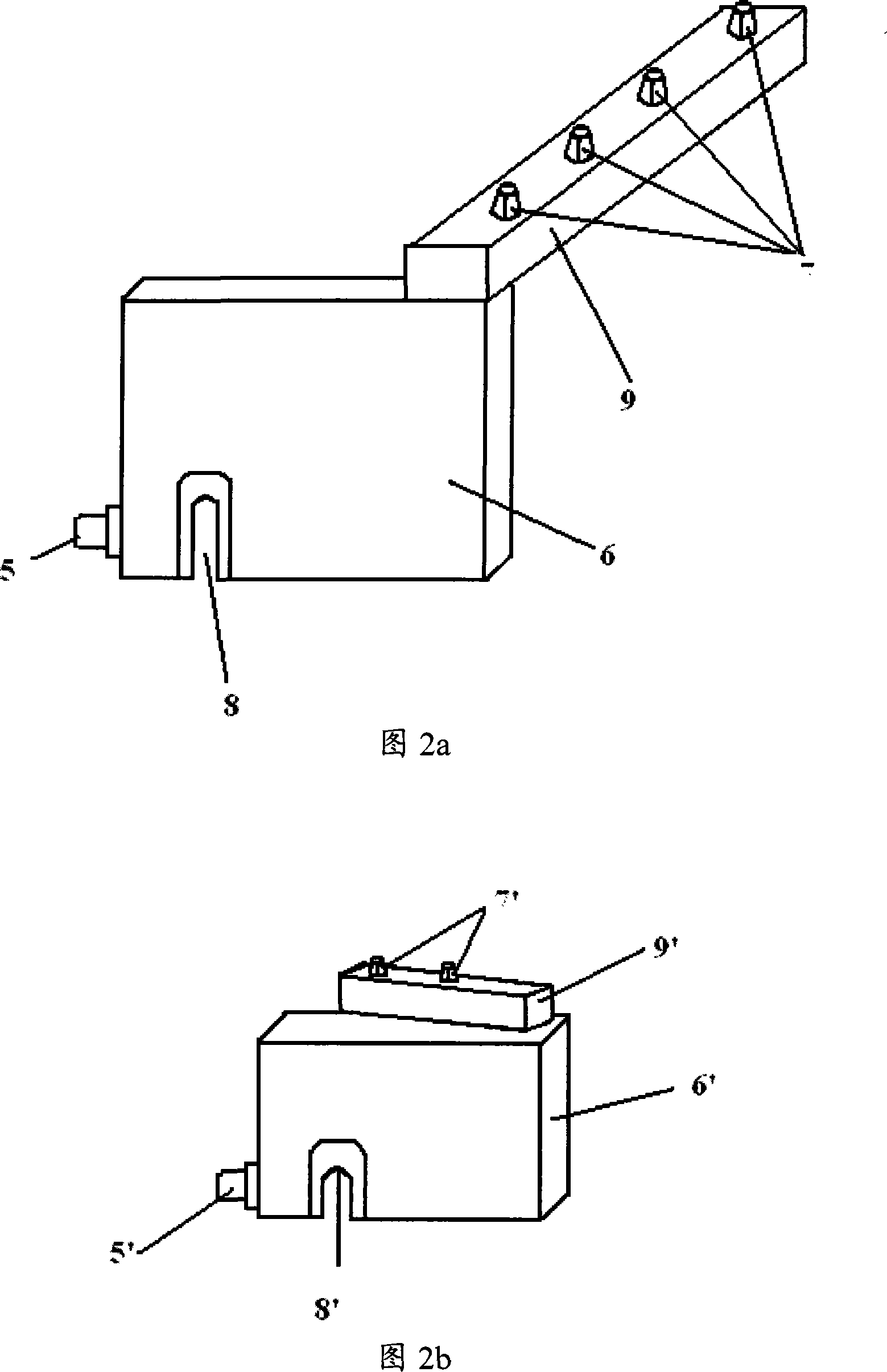

[0019] The spraying device com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com