Wafer grinding fluid and preparation method thereof

A technology of grinding liquid and wafer, applied in chemical instruments and methods, other chemical processes, petroleum industry, etc., can solve problems such as poor anti-rust performance, environmental pollution, troublesome cleaning, etc., to increase anti-rust ability and improve grinding quality , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

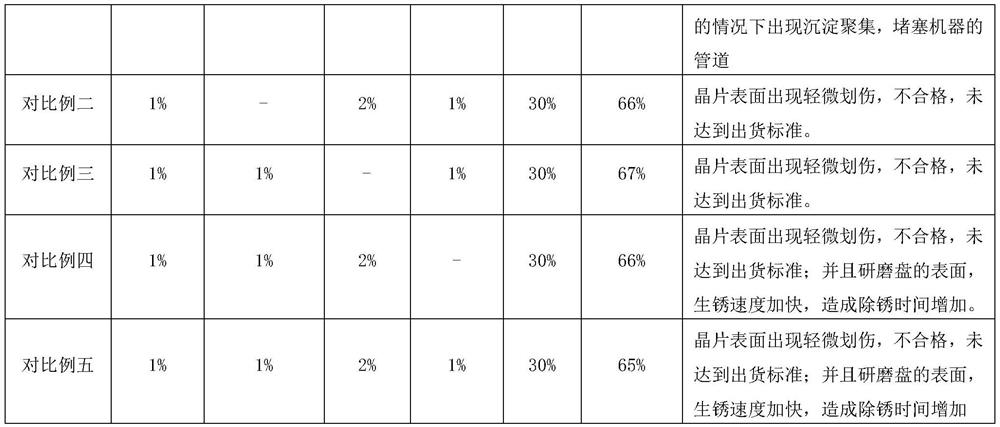

Examples

Embodiment 1

[0032] The grinding oil of this embodiment includes the following raw materials in mass percentage: 8% sodium azelate amide, 8% sodium laurate, 10% monoethanolamine, 15% triethanolamine, and 59% water.

[0033] The grinding liquid includes the following raw materials in mass percentage: 30% grinding powder, 1% grinding oil, 1% dispersant, 1% surfactant, 2% chelating agent, and 65% deionized water.

[0034] Grinding Oil Preparation

[0035] According to the proportion, each raw material was weighed respectively, firstly, sodium azelaic acid amide was added into water, and continued to stir until it was completely dissolved, then sodium laurate was added, stirred to dissolve, then monoethanolamine and triethanolamine were added and stirred evenly to obtain grinding oil.

[0036] Grinding liquid preparation

[0037] According to the proportion, weigh the dispersing agent sodium hexametaphosphate, the surfactant polyethylene glycol, and the chelating agent edetate disodium, stir ...

Embodiment 2

[0039] The grinding oil of this embodiment includes the following raw materials in mass percentages: 10% sodium azelaic acid amide, 10% sodium laurate, 10% monoethanolamine, 25% triethanolamine, and 45% water.

[0040] Grinding fluid includes the following mass percentage raw materials: 30% grinding powder, 1.5% grinding oil, 1% dispersant, 1.5% surfactant, 2% chelating agent, 64% deionized water

[0041] The preparation of the grinding oil and the preparation method of the grinding liquid are the same as in Example 1.

Embodiment 3

[0043] The grinding oil of this embodiment includes the following raw materials in mass percentages: 8% sodium azelate amide, 8% sodium laurate, 10% monoethanolamine, 25% triethanolamine, and 49% water.

[0044] The grinding solution includes the following raw materials in mass percentage: 30% grinding powder, 1.5% grinding oil, 1.5% dispersant, 1.5% surfactant, 2% chelating agent, and 63.5% deionized water.

[0045] The preparation of the grinding oil and the preparation method of the grinding liquid are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com