A kind of wafer polishing liquid and preparation method thereof

A technology for grinding fluid and wafers, applied in chemical instruments and methods, other chemical processes, lubricating compositions, etc., can solve problems such as poor anti-rust performance, environmental pollution, troublesome cleaning, etc., to increase anti-rust ability and improve grinding quality, damage reduction effect

Active Publication Date: 2022-06-10

威科赛乐微电子股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Oil agent mainly has good viscosity, lubrication and anti-rust performance, but it is troublesome to clean and pollutes the environment

In the process of grinding wafers, water-based abrasives are preferred, but the disadvantage of water-based abrasives is that they have poor anti-rust performance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

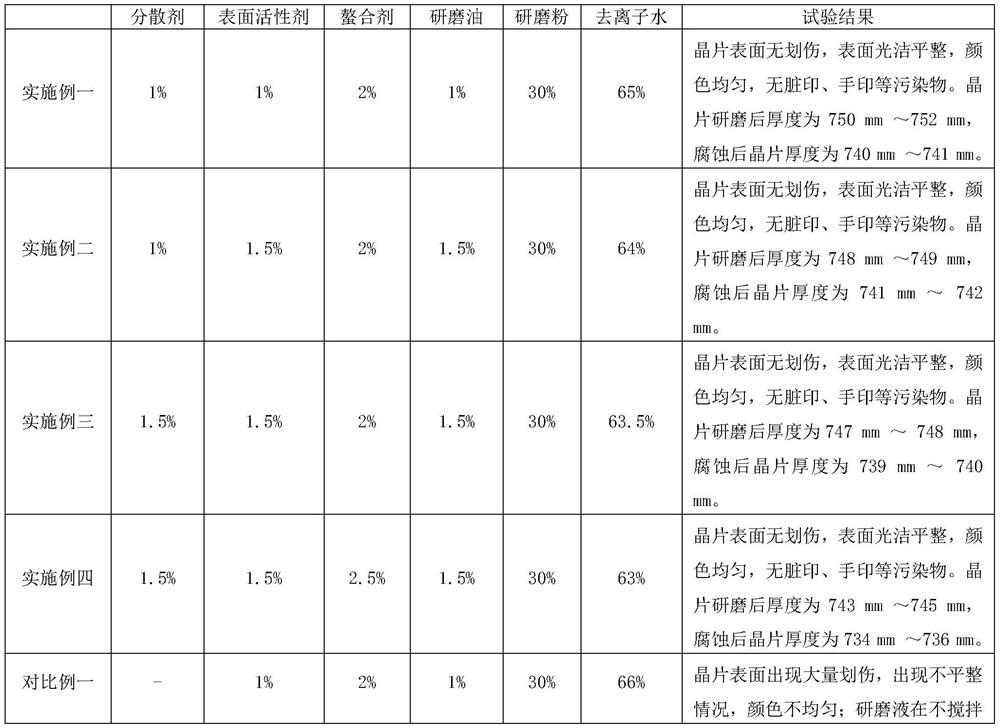

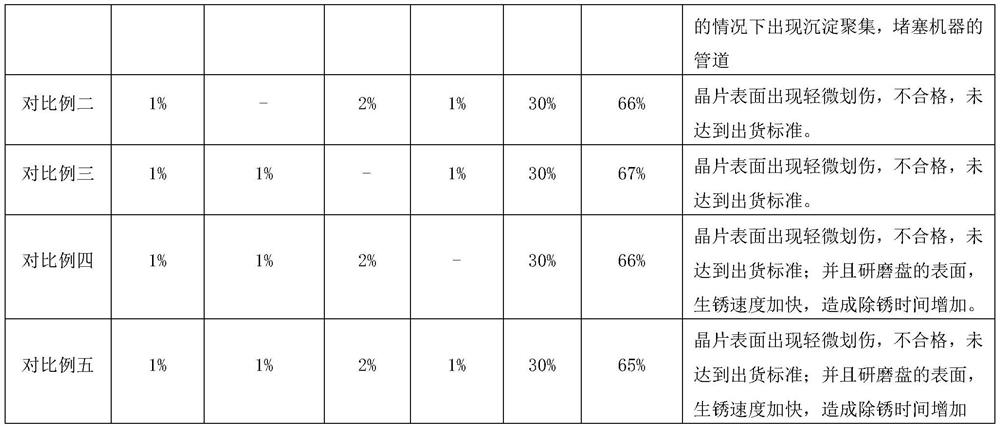

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a wafer grinding liquid and a preparation method thereof, and relates to the technical field of semiconductor materials. A kind of wafer grinding liquid of the present invention, raw material comprises grinding powder, grinding oil, dispersant, surfactant, chelating agent, deionized water, and its preparation method is, respectively weighs dispersing agent, grinding oil, surfactant, chelating Stir and mix the mixture evenly to obtain a mixed solution, add the mixed solution to the grinding powder, continue stirring to disperse, pour it into deionized water, continue stirring and mixing for 30-60 minutes, add grinding oil, continue to stir and mix evenly, use a high-density filter Filter twice to obtain grinding liquid. The invention discloses a wafer grinding liquid and a preparation method thereof. Through the joint action of various components, the antirust ability of the grinding disc is increased, and the grinding efficiency and grinding quality can be improved.

Description

A kind of wafer grinding liquid and preparation method thereof technical field [0001] The present invention relates to the technical field of semiconductor materials, in particular to a wafer lapping liquid and a preparation method thereof. Background technique [0002] In the entire semiconductor material processing, the grinding process is a very important process. The main work of grinding The use is to use the abrasive particles coated or pressed on the grinding tool, through the relative movement of the grinding tool and the workpiece under a certain pressure. Finishing (such as cutting) performed on the work surface. Grinding can be used to process a variety of metal and non-metallic materials, the processing of the table Surface shapes include plane, inner and outer cylindrical and conical surfaces, convex and concave spherical surfaces, threads, tooth surfaces and other profiles. Grinding fluid main body is divided into two kinds of oil agent and water agent,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K3/14C10M173/02C10N30/12C10N30/06

CPCC09K3/1463C10M173/02C10M2215/08C10M2207/127C10M2215/042C10M2201/085C10M2209/104C10M2215/04C10M2201/062

Inventor 毕洪伟周一刘留苏小平王春平

Owner 威科赛乐微电子股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com