Brake with drum type floating brake shoe bidirectional propulsion structure

A technology of brakes and brake shoes, which is applied in the direction of mechanically driven drum brakes, brake actuators, brake parts, etc., can solve the problems of uneven force on the brake hub, rising temperature, and reducing vehicle speed, etc., to achieve Eliminate driving safety hazards, uniform temperature rise, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

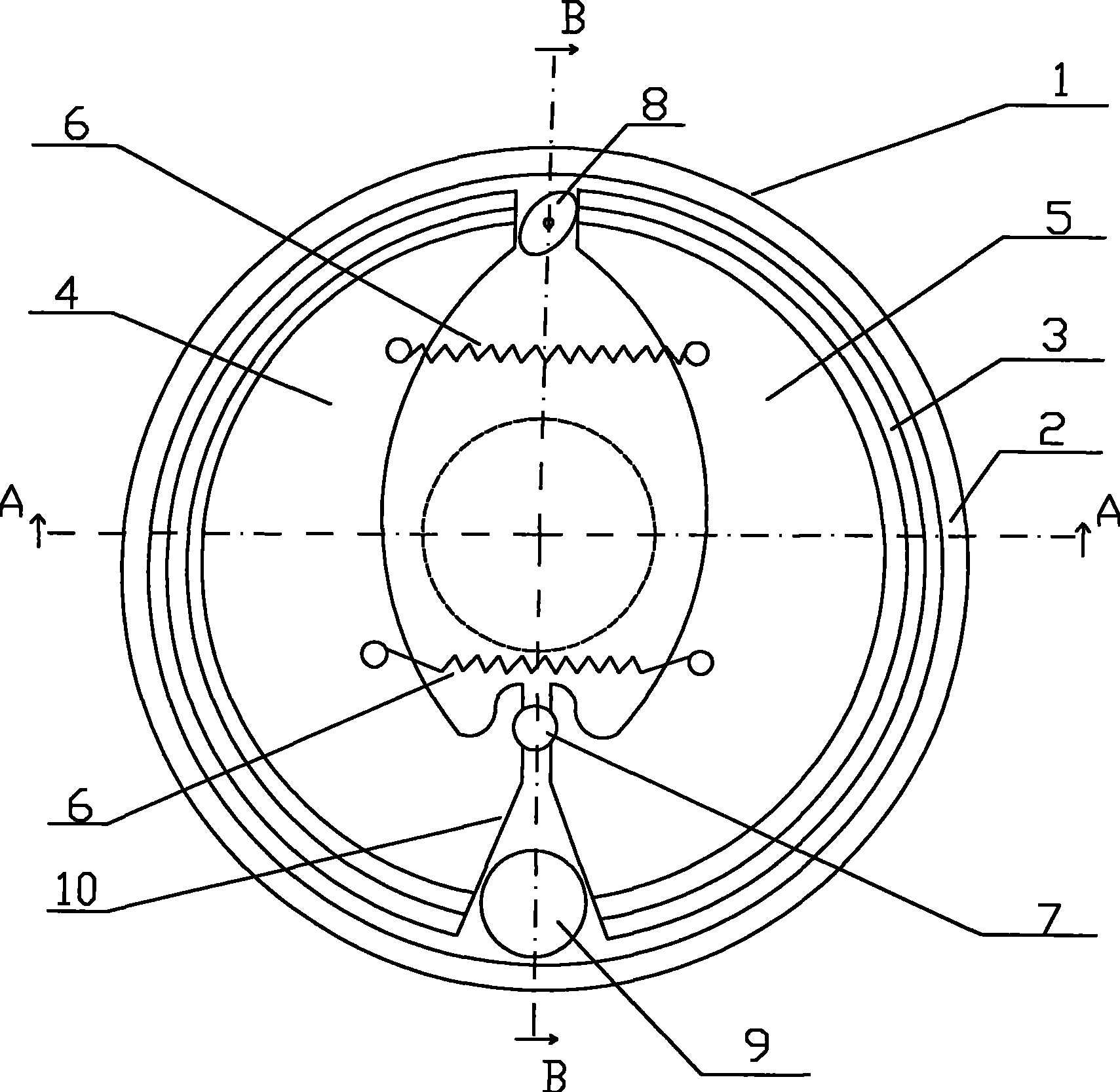

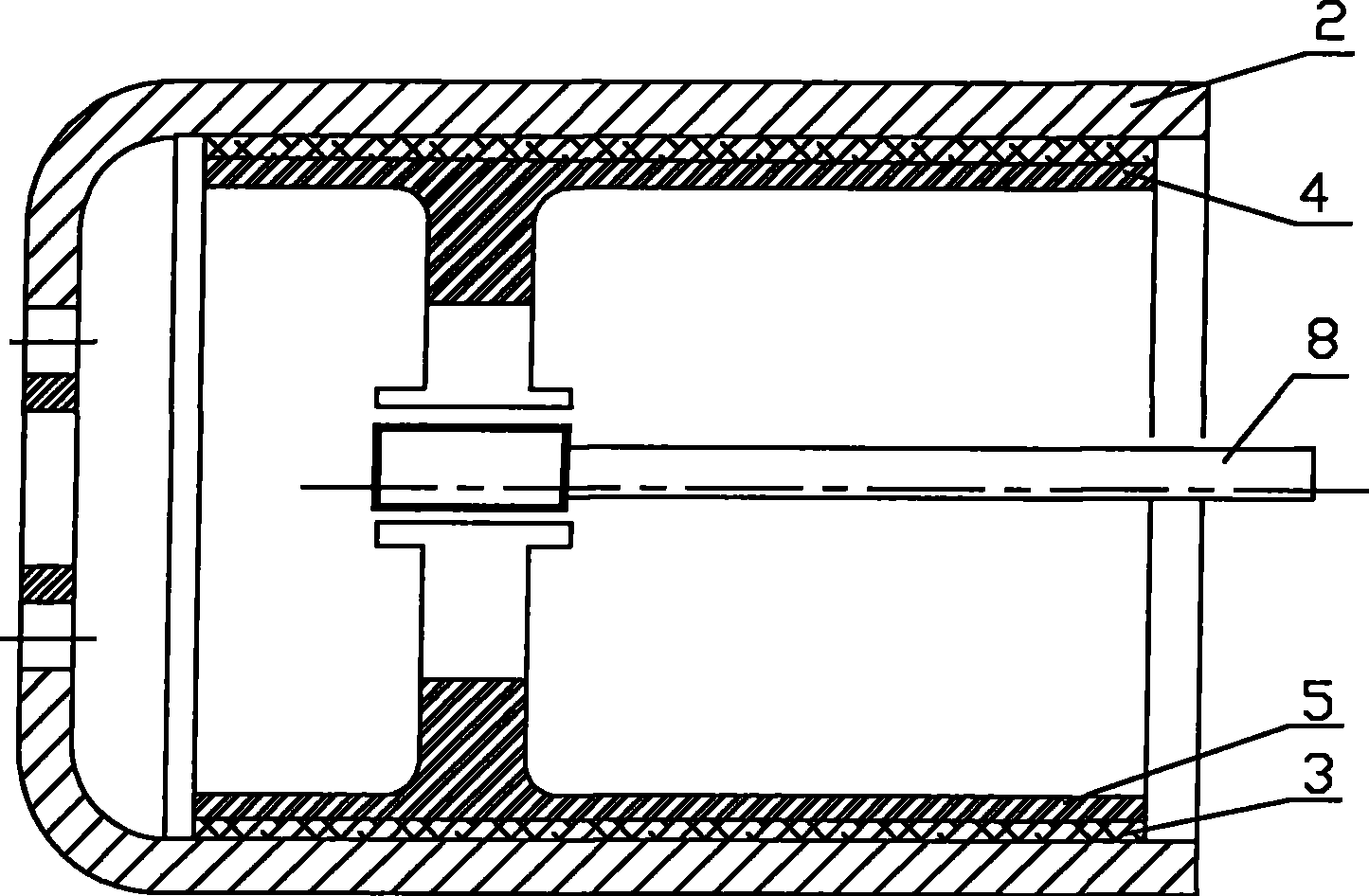

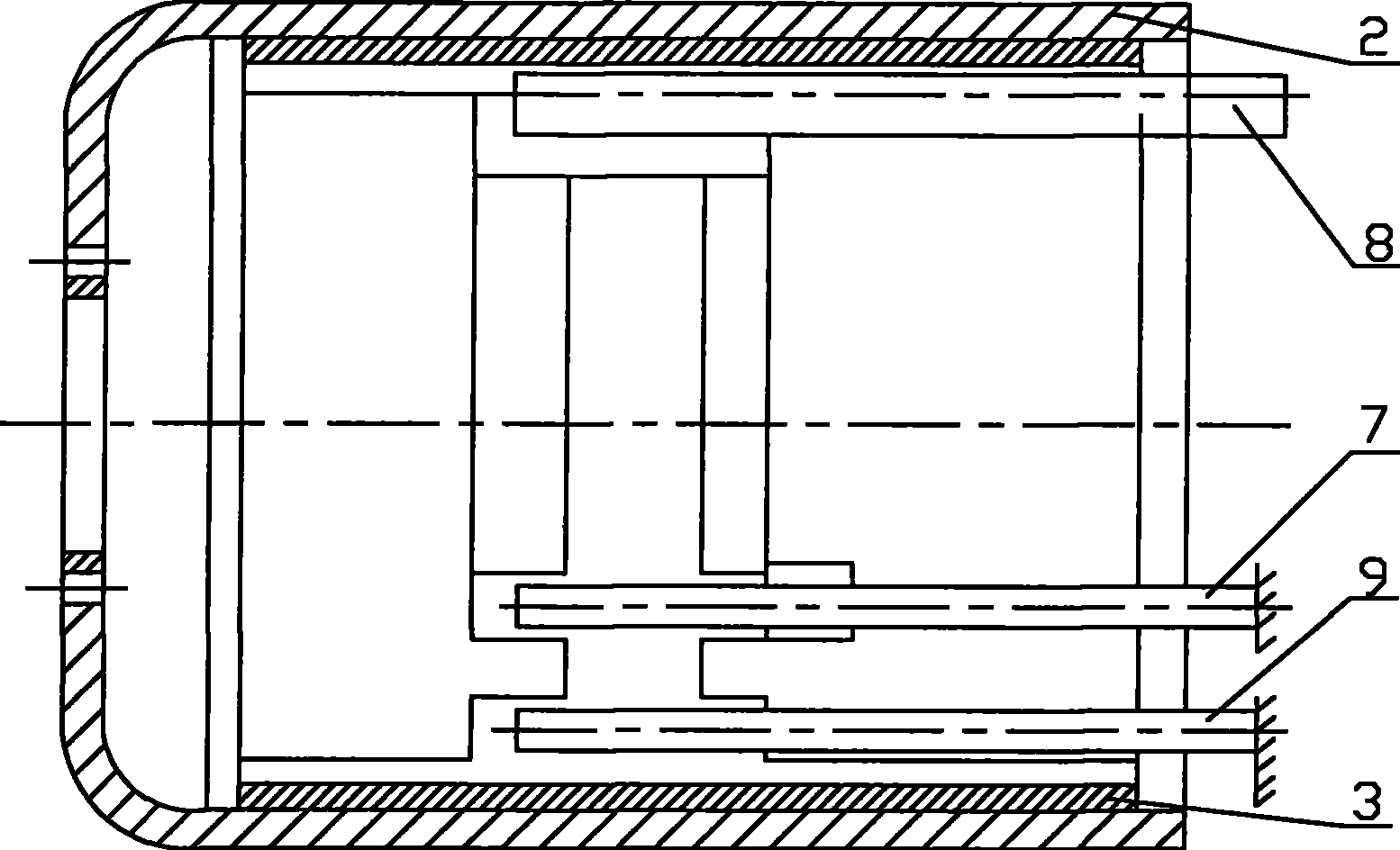

[0016] Such as figure 1 , 2 , 3, 1—brake body, 2—brake hub, 3—friction plate, 4—left brake shoe, 5—right brake shoe, 6—extension spring, 7—hinge column, 8—cam, 9—garden pin, 10—inclined plane;

[0017] The drum-type floating brake shoe bidirectional push structure brake of the present invention includes a brake body 1, and the brake body 1 is mainly composed of a circular brake hub 2, a friction plate 3, a left brake shoe block 4, a right brake shoe block 5, The hinge column 7 and the cam 8 are composed, and the left brake shoe 4 and the right brake shoe 5 are provided with friction plates 3 (usually connected by riveting), and the left brake shoe 4 and the right brake shoe 5 The friction plate 3 is in contact with the inner working surface of the brake hub 2, and the left brake shoe 4 and the right brake shoe 5 are arranged in the inner cavity of the circular brake hub 2; the left brake shoe 4 and the right brake shoe Extension springs 6 are arranged between the moving sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com