Concrete plane complicated applied force test device

A test device, concrete technology, applied in the direction of measuring device, using stable shear force to test material strength, using stable tension/compression to test material strength, etc., can solve the complicated stress situation at the end of concrete specimens, etc. problems, to achieve high test accuracy and efficiency, improve test efficiency, and facilitate the removal of test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

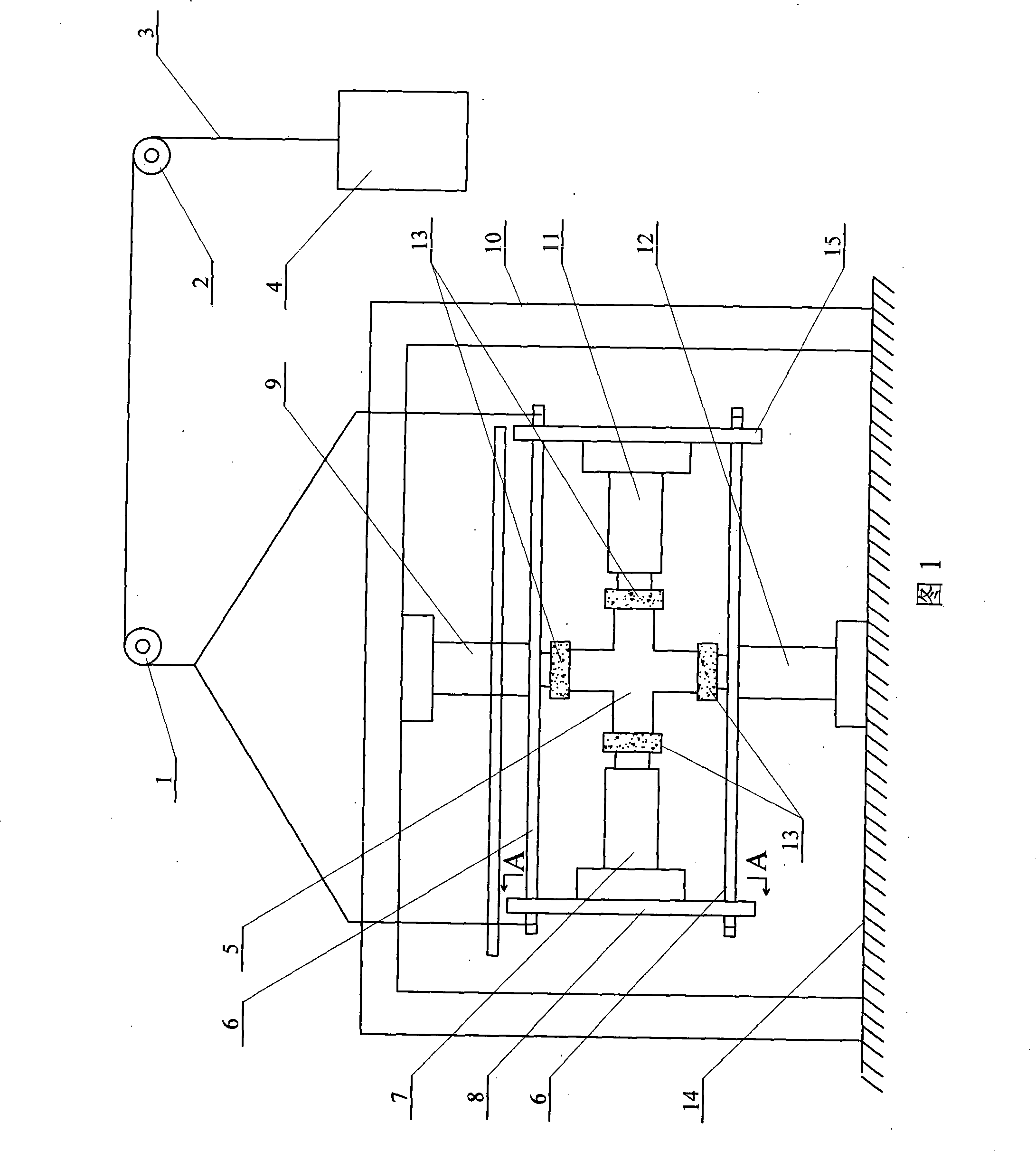

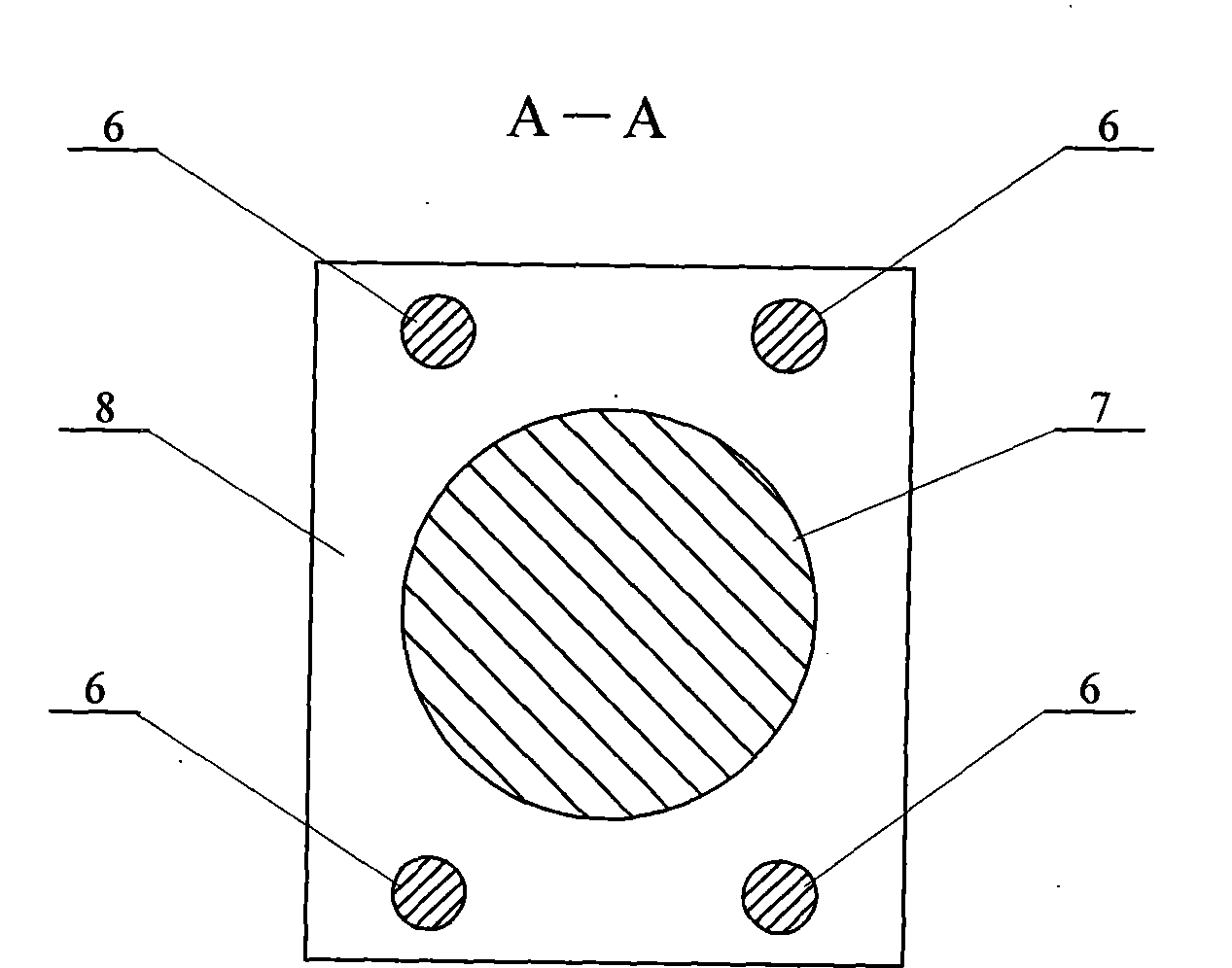

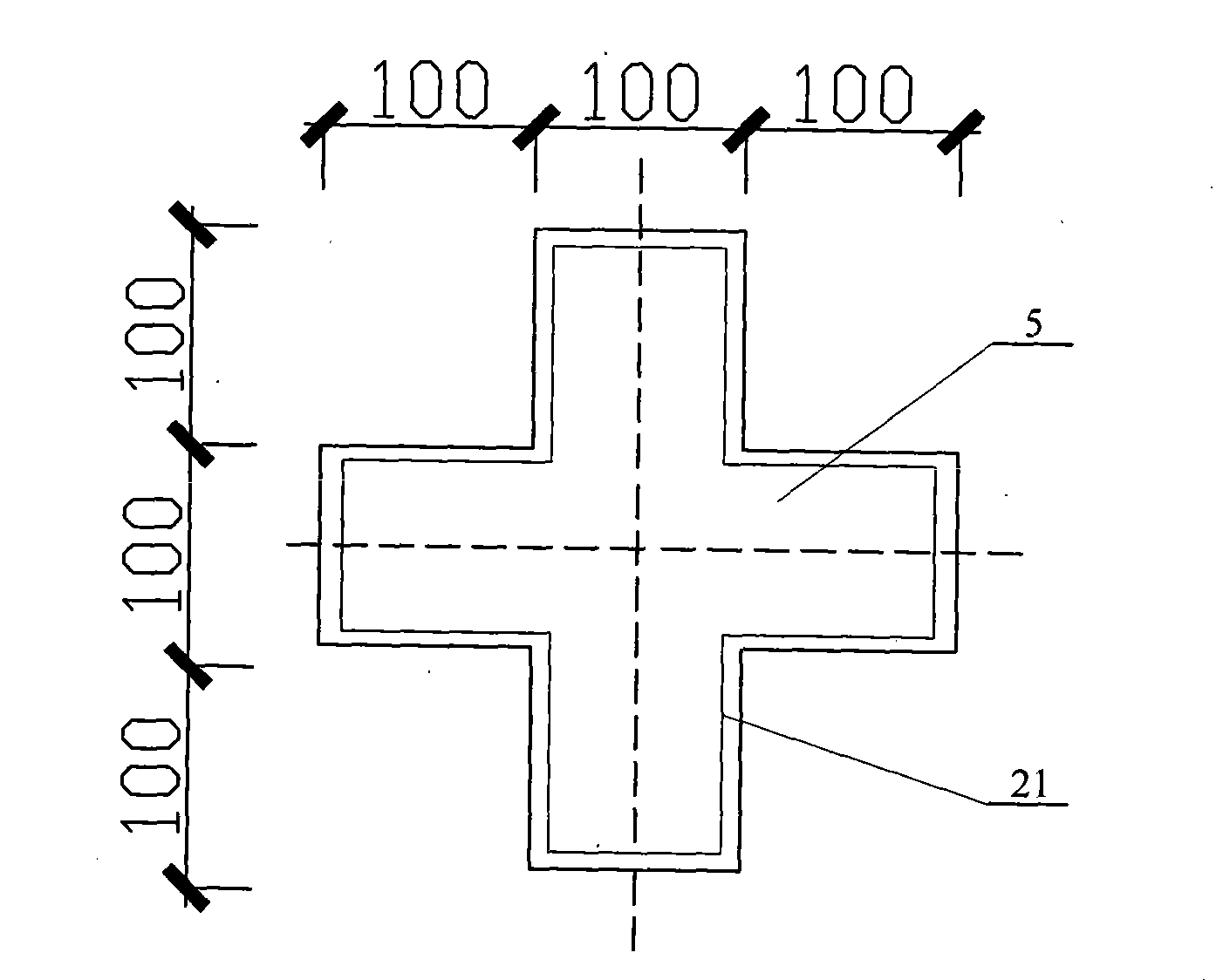

[0007] Specific implementation mode one: (see figure 1 with figure 2 ) This embodiment consists of a first fixed pulley 1, a second fixed pulley 2, a steel wire rope 3, a counterweight 4, four screw rods 6, a first horizontal loader 7, a first steel plate 8, a first vertical loader 9, The reaction force frame 10, the second horizontal loader 11, the second vertical loader 12, four pressure bearing plates 13 and the second steel plate 15 are composed. The lower ends of both sides of the reaction force frame 10 are fixed on the ground 14, and the second vertical loader The loader 12 is fixed on the ground 14 of the center position in the reaction frame 10, the first vertical loader 9 is fixed on the lower side of the center position of the crossbeam of the reaction frame 10, the first vertical loader 9 and the second vertical The free ends of the loader 12 are arranged oppositely up and down and have the same axis. The first steel plate 8 and the second steel plate 15 are arra...

specific Embodiment approach 2

[0008] Specific implementation mode two: (see figure 1 ) In this embodiment, the outer side of the first fixed pulley 1 , that is, the downward trajectory of the wire rope 3 is the same as the axes of the first vertical loader 9 and the second vertical loader 12 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: (see Image 6 ) The pressure bearing plate 13 of this embodiment is composed of a base plate 17, a backing plate 18 and a sleeve 19. A convex spherical cap 16 is provided on one side of the base plate 17, and a convex spherical cap 16 is provided on the backing plate 18 to cooperate with the convex spherical cap 16. The concave surface 20 of the base plate 17 is arranged corresponding to the backing plate 18, and the backing plate 18 is connected with the sleeve 19. Concrete specimens are casted with steel molds, but sometimes the four loading surfaces of concrete specimens cannot be absolutely guaranteed to be perpendicular to each other, and it is impossible to ensure the absolute translation of the bearing plate during loading, so the pressure bearing plate of the concrete compression test is designed It is a spherical hinge support to accommodate rotation in two vertical directions. A convex spherical cap 16 is provided on the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com