Fire-proof general-purpose test device of wall, column and frame node structures

A node structure and test device technology, applied in the direction of machine/structural component testing, measuring devices, material inspection products, etc., can solve problems such as inconsistencies with actual conditions, and achieve easy production, good economy, and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

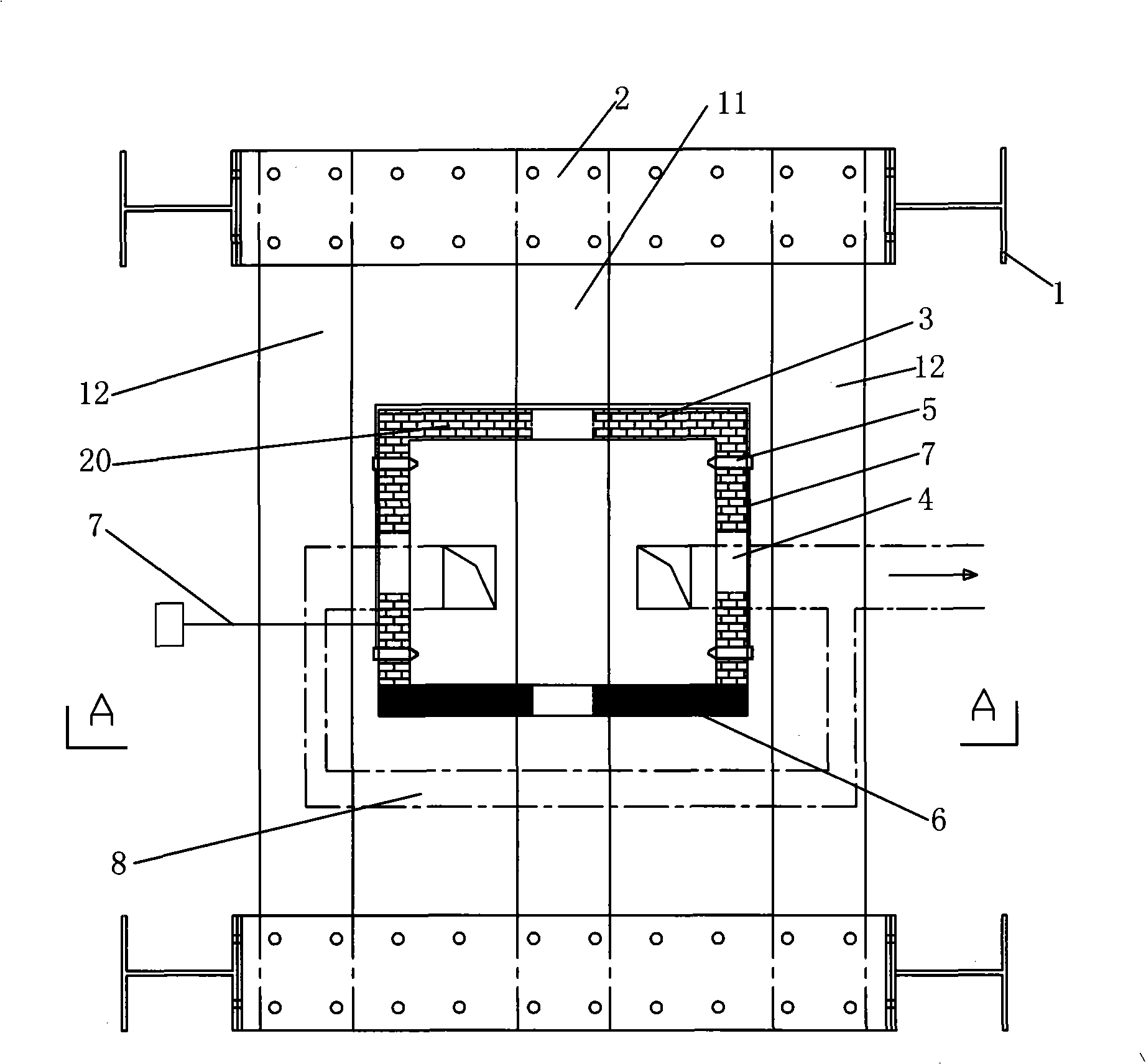

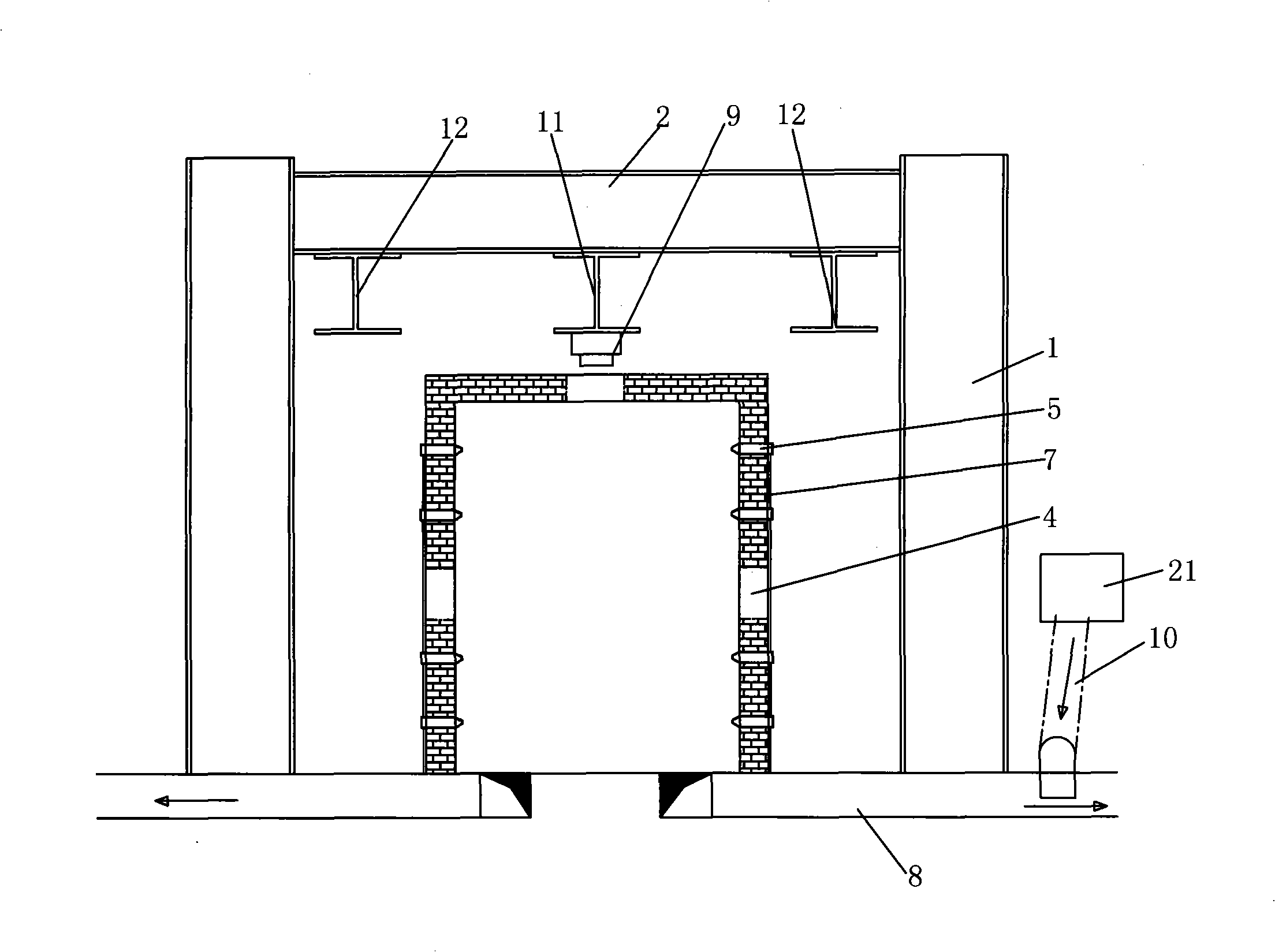

[0011] Embodiment: according to the component size that will carry out fire performance test: column height (H=3.3m) and the size of frame node (column height H=3.0m that is connected with node, the beam length L=1.35m that is connected with node, The size of the test wall is length × height = 3.3m × 3.0m, and finally the size of the furnace body is determined as: height × width × thickness = 3.3m × 3.0m × 2.0m. Holes of 400mm × 600mm are set in the middle of the four sides of the furnace body. The furnace wall is surrounded by I-beam 20 as the skeleton, and the inner wall is made of 200mm zirconium-containing refractory fiber cotton. The column is made of 500mm×500mm H-shaped steel, and the beam is welded by steel plate to form a beam with a height of 800mm. When performing the fire resistance test of the wall, Remove the movable surface 6 of the furnace body, install the test wall at the position of the movable surface 6, and connect it reliably with the fixed surface 3 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com