Method for sterilizing edible fungus at normal atmosphere

A technology of atmospheric pressure sterilization and edible fungus, applied in botany equipment and methods, applications, gardening, etc., can solve the problems of low biological conversion rate, slow mycelium feeding, and pollution of culture material bags, etc., and achieve biological The effect of high conversion rate, short time for full bag and high bag output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

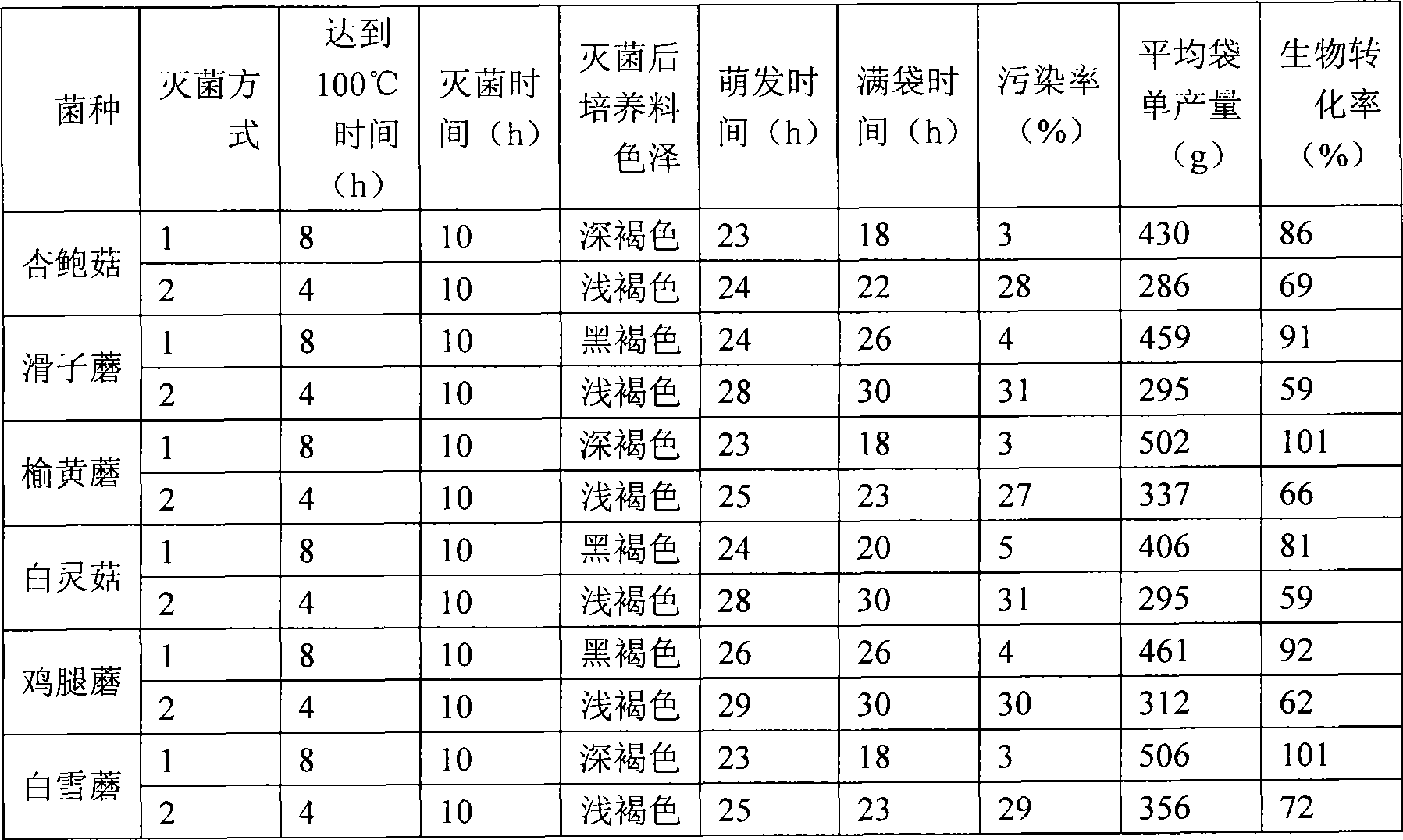

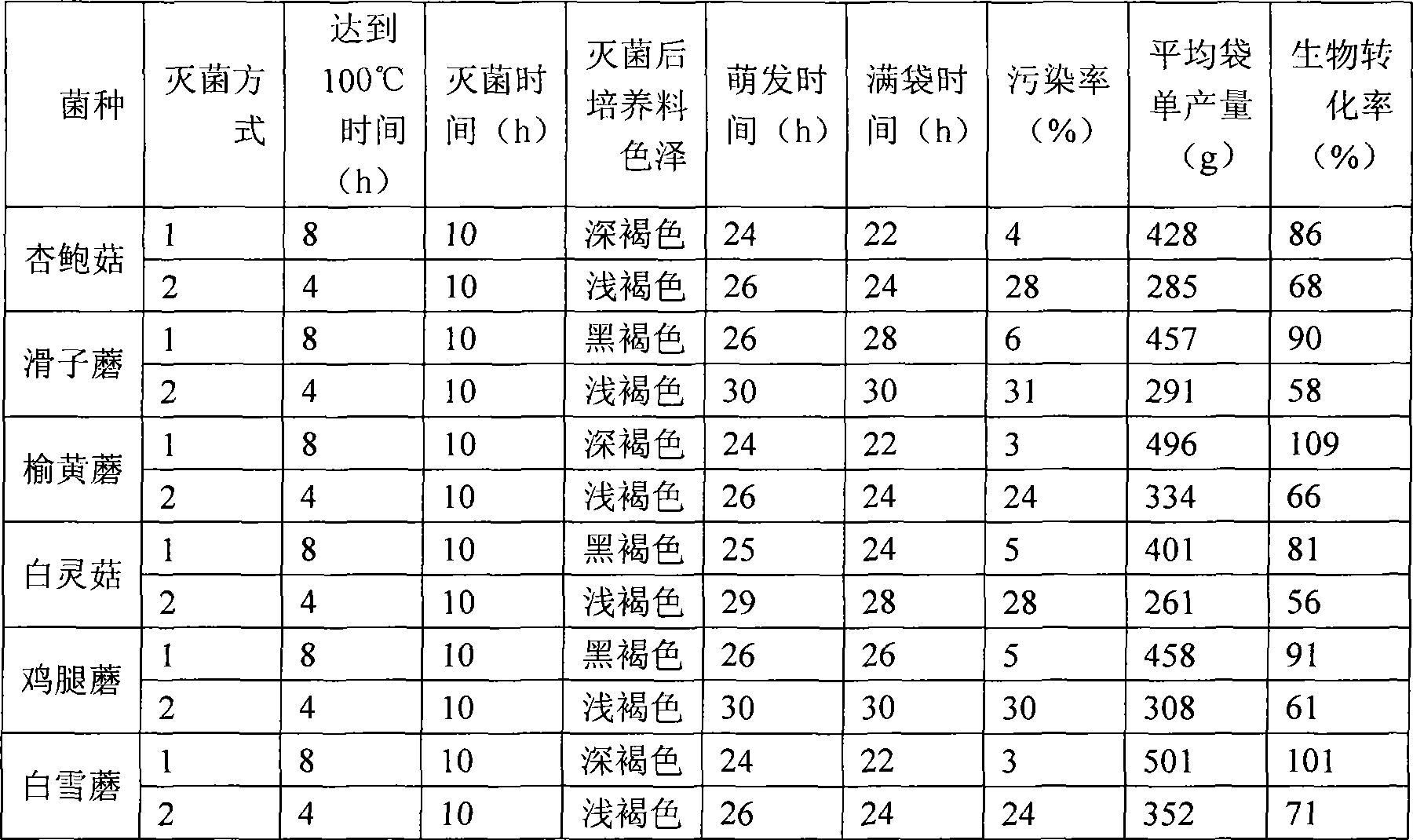

Examples

Embodiment 1

[0045] In each of the following examples, the compost was prepared according to the formula of compost 1 in the above-mentioned test example.

[0046] 1. Pack the culture material into bags: the culture material bag is a plastic bag with a diameter of 17cm x a length of 35cm. The thickness of the plastic bag is 0.004cm, and each bag is filled with 500 grams of culture material equivalent to dry material;

[0047] 2. Put the loaded culture material bags into the atmospheric pressure sterilization device: first put 6 culture material bags vertically and tightly into the iron basket, and place 10 baskets on each layer in the atmospheric pressure sterilization device, stacking them in total 8 layers, the temperature sensor is placed in the center between the third layer and the fourth layer from the bottom layer;

[0048]3. Heat sterilization: heat the atmospheric pressure sterilization device, and when the temperature sensor reaches 100°C, keep the temperature and continue to ste...

Embodiment 2

[0051] 1. Pack the culture material into bags: the culture material bag is a plastic bag with a diameter of 17cm x a length of 35cm. The thickness of the plastic bag is 0.004cm, and each bag is filled with a culture material equivalent to 525 grams of dry material;

[0052] 2. Put the loaded culture material bags into the atmospheric pressure sterilization device: first put 6 culture material bags vertically and tightly into the iron basket, and place 50 baskets on each layer in the atmospheric pressure sterilization device, stacking them in total 9 layers, the temperature sensor is placed in the center between the third layer and the fourth layer from the bottom layer;

[0053] 3. Heat sterilization: heat the atmospheric pressure sterilization device, and when the temperature sensor reaches 100°C, keep the temperature and continue to sterilize for 10 hours;

[0054] 4. Cooling and discharging: After stopping heating, discharge when the temperature of the material drops to 45°...

Embodiment 3

[0056] 1. Pack the culture material into bags: the culture material bag is a plastic bag with a diameter of 17cm x a length of 35cm. The thickness of the plastic bag is 0.004cm, and each bag is filled with 550 grams of culture material equivalent to dry material;

[0057] 2. Put the loaded culture material bags into the atmospheric pressure sterilization device: first put 6 culture material bags vertically and tightly into the iron basket, and place 100 baskets on each layer in the atmospheric pressure sterilization device, stacking them in total 10 layers, place the temperature sensor in the center between the third and fourth layers from the bottom;

[0058] 3. Heat sterilization: heat the atmospheric pressure sterilization device, and when the temperature sensor reaches 100°C, keep the temperature and continue to sterilize for 11 hours;

[0059] 4. Cooling and discharging: After stopping heating, discharge when the temperature of the material drops to 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com