Module type pulse conversion turbocharging system with scaling type exhaust pipe

A technology of turbocharging system and exhaust branch pipe, which is applied to gas turbine devices, machines/engines, internal combustion piston engines, etc., can solve the problems of low turbine efficiency, small exhaust pipe volume, and poor low-load performance of the supercharging system, etc. Achieve the effect of excellent performance, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

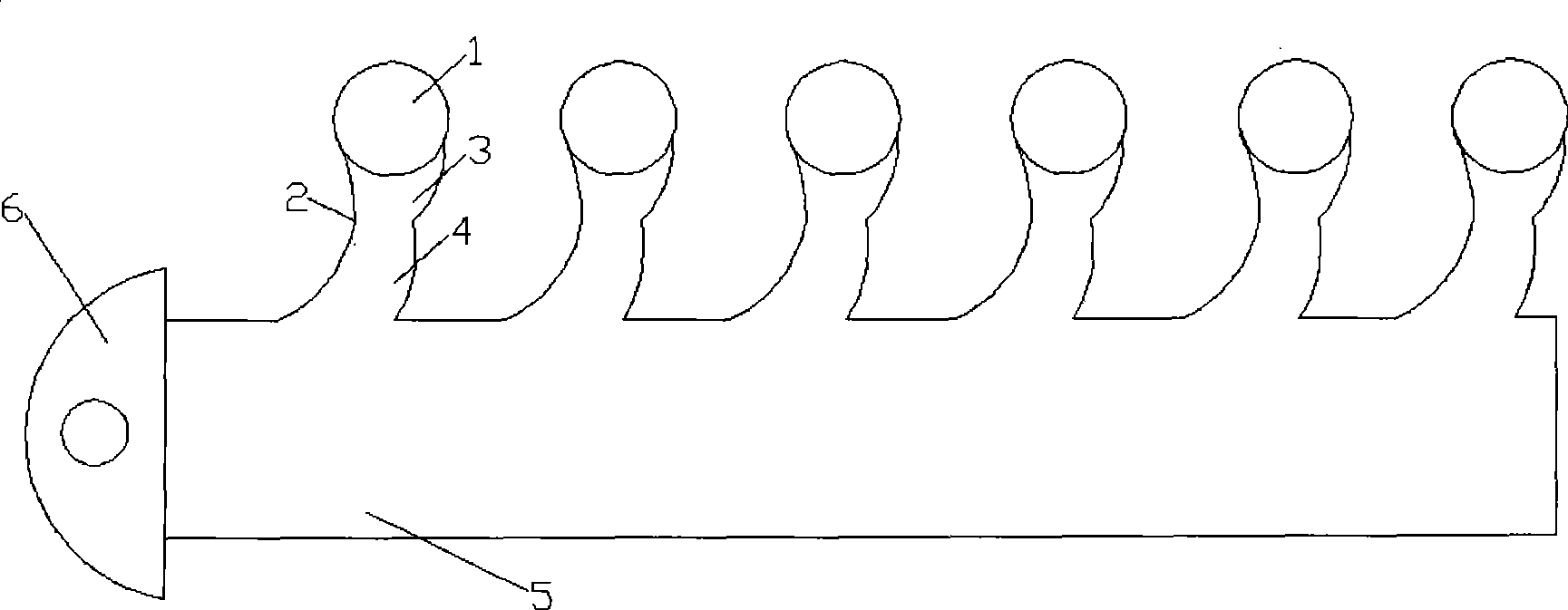

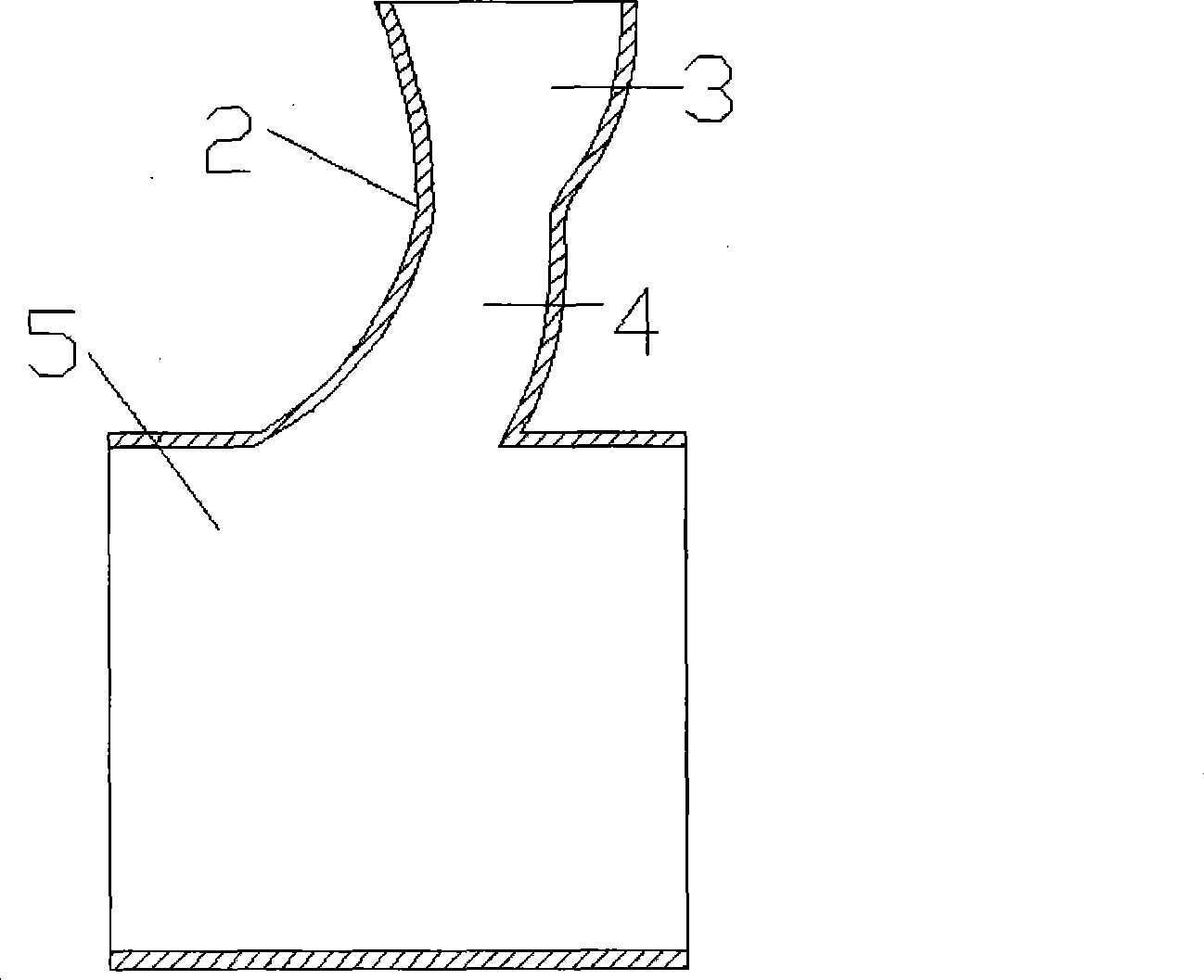

[0010] Such as figure 1 , figure 2 Shown, the present invention comprises cylinder 1, exhaust branch pipe 2, exhaust pipe 5 and turbine 6, and cylinder 1 is connected with exhaust pipe 5 by exhaust branch pipe 2, and turbine 6 is a single inlet, and the outlet of exhaust pipe 5 is connected with exhaust pipe 5. The inlets of the turbine 6 are connected, and the exhaust branch pipe 2 is smoothly connected by a reducer 3 with a gradually reduced cross-sectional area and an expander 4 with a gradually enlarged cross-sectional area. After optimized calculation, the inlet diameter of the reducer 3 and the outlet diameter of the expander 4 are equal, and the ratio of the outlet sectional area of the reducer 3 to the inlet sectional area of the reducer 3 ranges from 0.6 to 0.9. Here, the inlet of the reducer 3 is the inlet of the exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com