Method for detecting floor substrate water absorption expansion rate and water absorption height

A technology of water absorption expansion rate and detection method, which is applied in the field of architectural decoration, can solve problems such as ugly appearance, affecting the appearance of composite floors, and inability to fully express the degree of water absorption and expansion of composite floors, so as to improve work efficiency and shorten the waiting time for detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

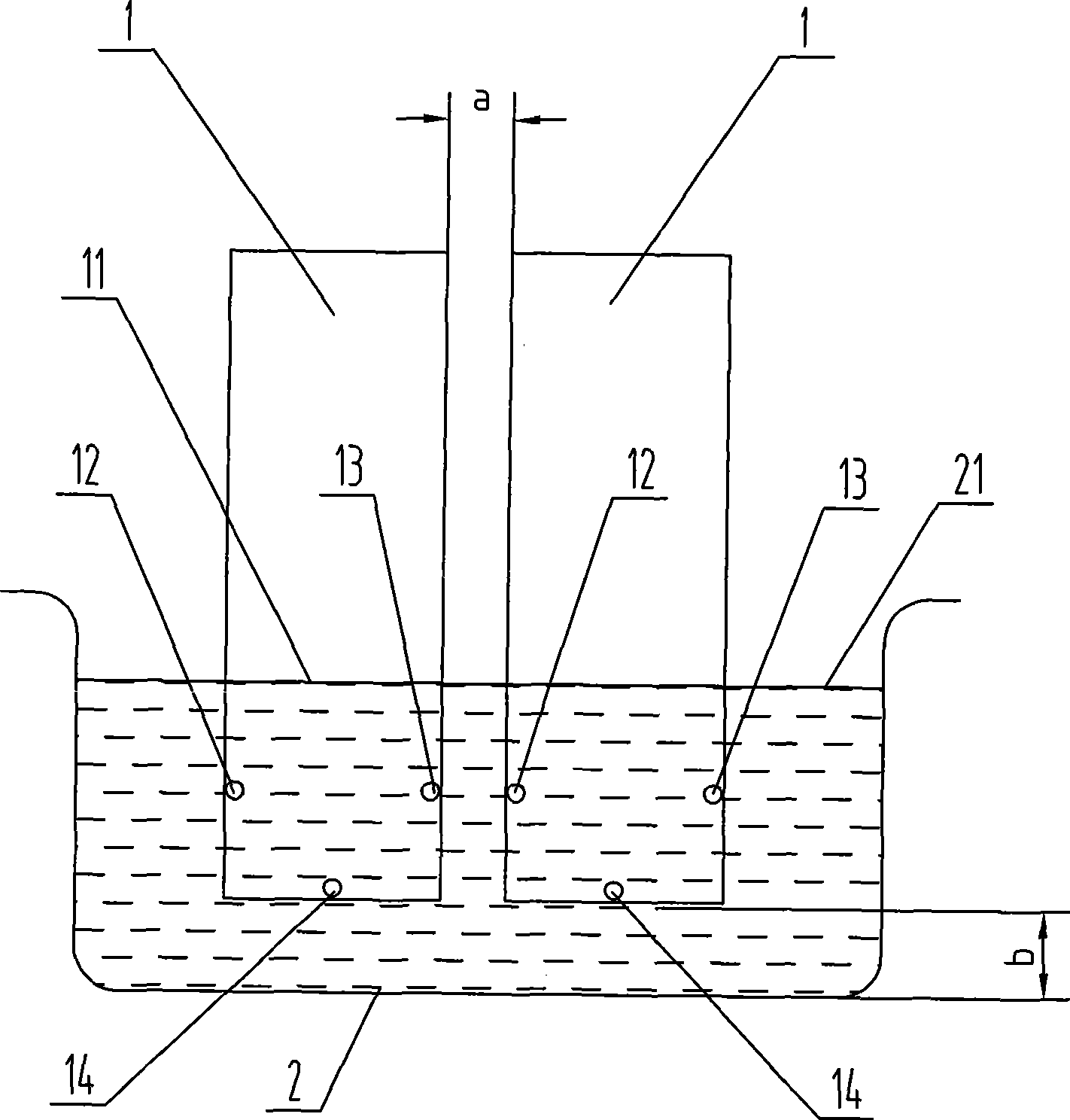

[0029] see figure 1 :

[0030] First, place two prepared 150mm×50mm floor substrate specimens at a room temperature of 20±2°C and a relative humidity of 65±5% for 24 hours to stabilize the water content.

[0031] Make the following marks on the floor substrate test piece: in the length direction of the floor substrate test piece, draw the immersion line 11 at 50 mm from the bottom, and draw the immersion line 11 at the midpoint of the 50 mm width at the bottom of the submerged part of the test piece, from the bottom to the top Mark 14, 12, 13 at the intersection of the horizontal line of 25mm and the height edges on both sides, and measure the thickness h of the three points 1 , and make a record.

[0032] Keep the distance a between the front and rear or left and right of the two test pieces 1 at a distance of 10-50mm, immerse them vertically in the water tank 2, fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com