Optical lens component

A technology of optical lenses and components, applied in optical components, optics, instruments, etc., to achieve the effect of improving imaging quality, improving imaging quality, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

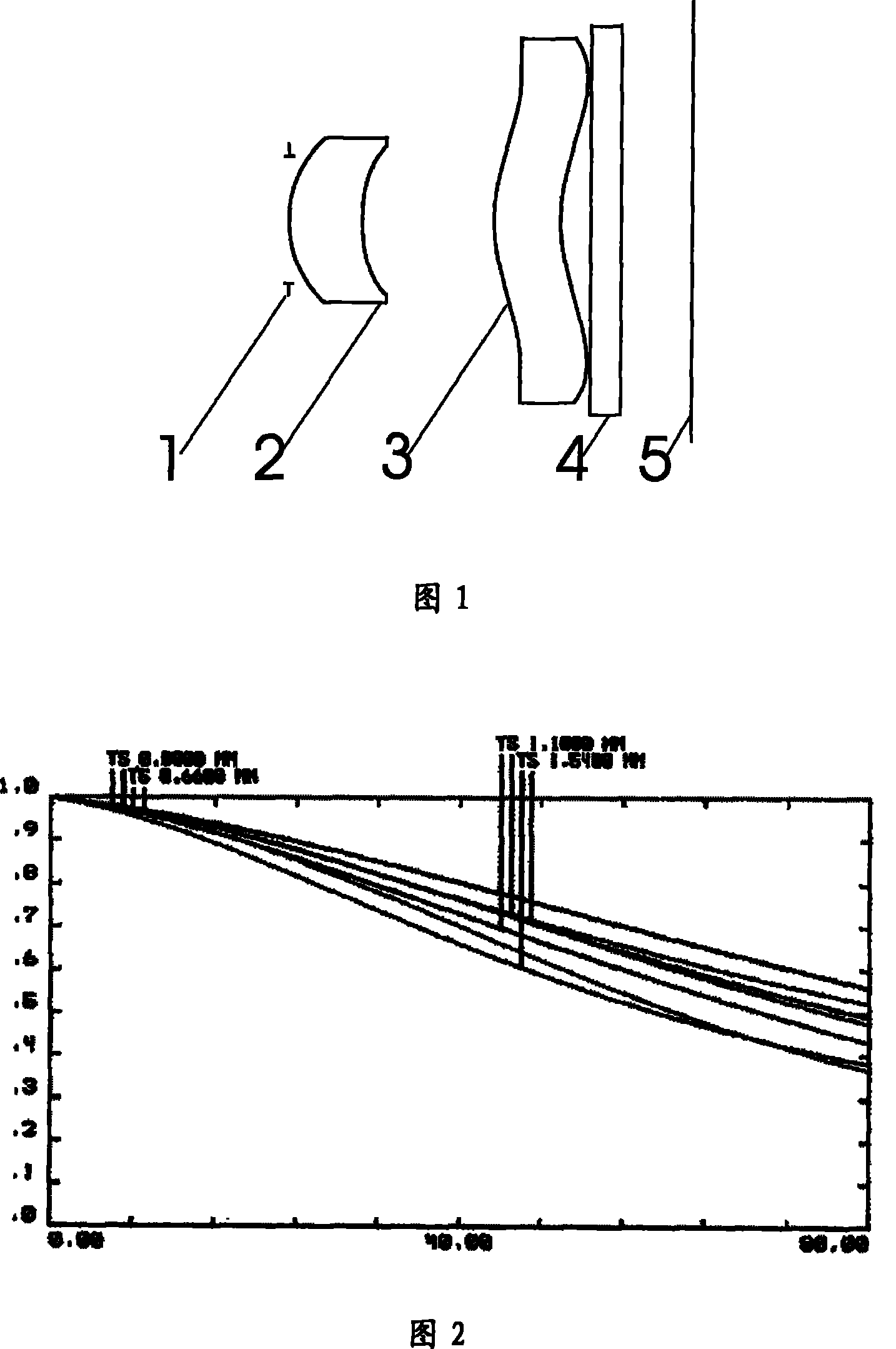

[0032] Such as Figures 1 to 12 As shown, an optical lens assembly includes a lens group, which is composed of a first lens 2 with a positive diopter and a second lens 3 with a negative diopter that have a common optical axis and are arranged in sequence from the object direction image side, Wherein the first lens 2 has a first surface facing the object side and a second surface facing the image side, the first surface protrudes toward the object side, and the second surface is concave relative to the image side; the second The lens 3 has a third surface facing the object side and a fourth surface facing the image side. The third surface is wavy with the middle part protruding toward the object side, and the two sides are concave relative to the object side. The four surfaces are wavy in which the middle part is concave relat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com