Display device with flip-chip structure

A display device and flip-chip technology, which is applied to electrical components, electrical solid devices, circuits, etc., can solve problems such as uneven distribution of connection bumps, uneven pressure, and poor bonding of conductive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

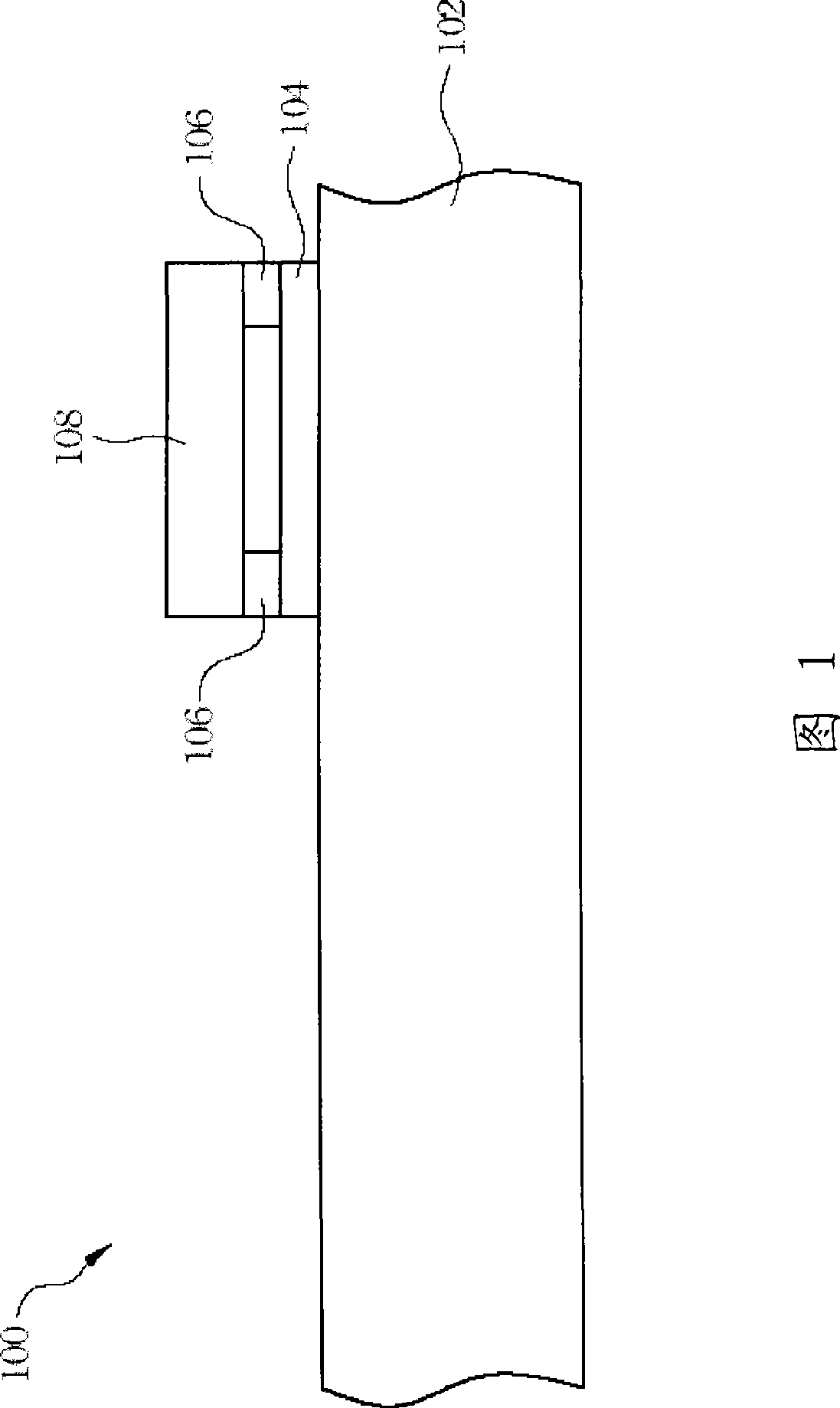

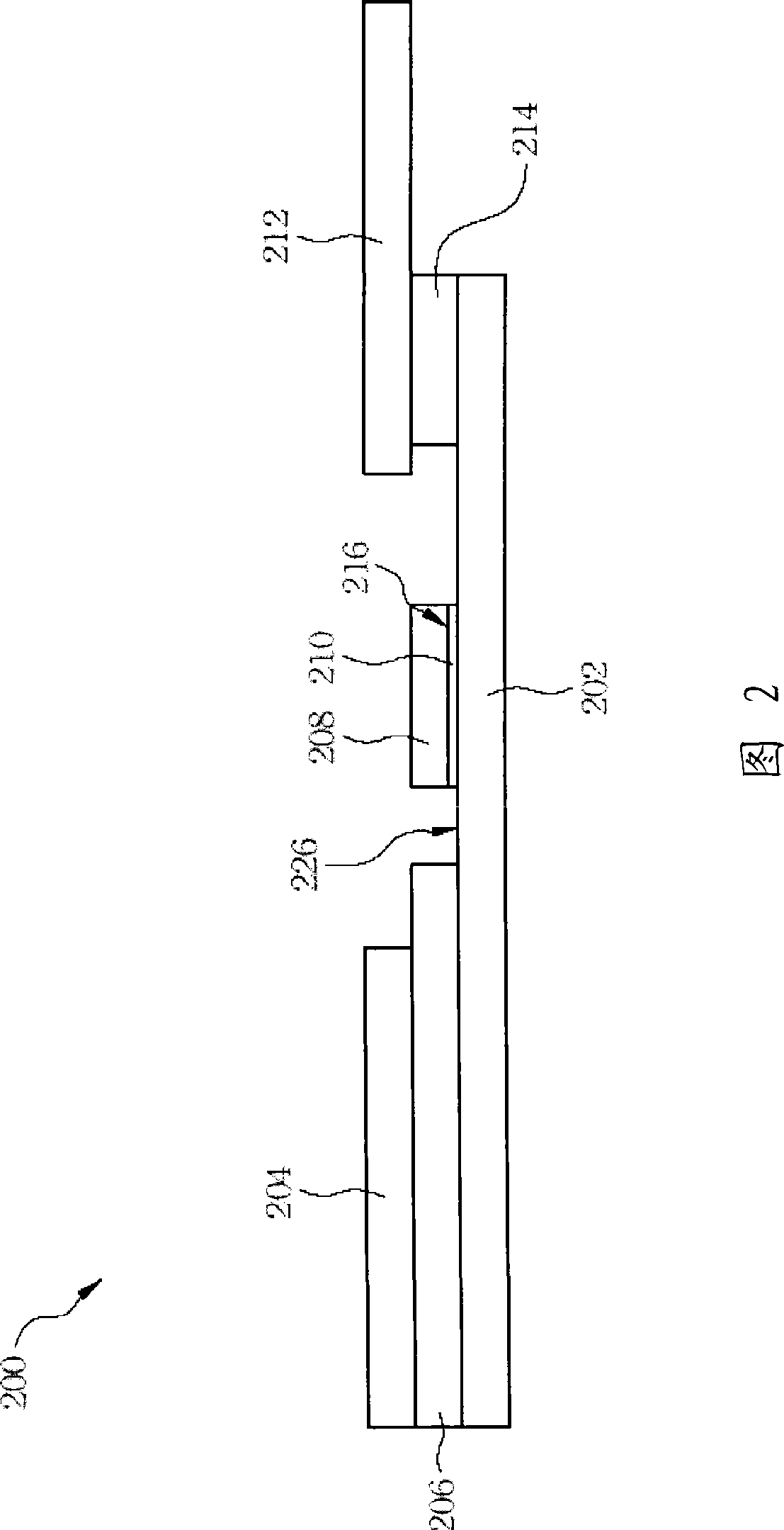

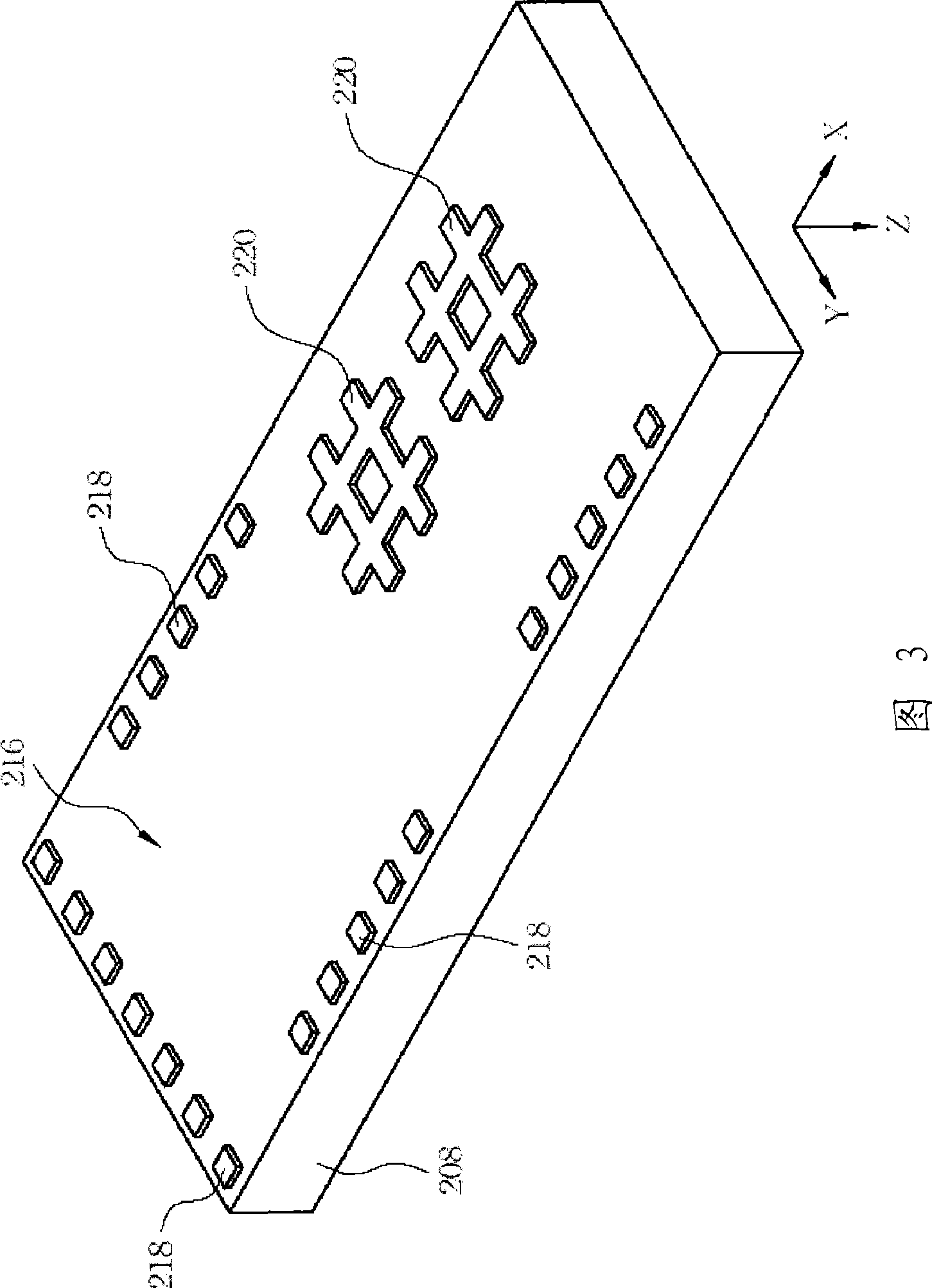

[0028] The invention discloses a display device with a flip-chip structure, which can greatly improve the lamination yield of the flip-chip process, and can strengthen the structural strength of the integrated circuit chip. In order to make the description of the present invention more detailed and complete, reference may be made to the following description together with the illustrations in FIGS. 2 to 4B .

[0029] Please refer to FIG. 2 , which is a schematic cross-sectional view of part of a display device with a flip-chip structure according to a preferred embodiment of the present invention. The display device 200 with a flip-chip structure includes a first substrate 202, wherein a display layer 206 is disposed on the first substrate 202, and the material of the first substrate 202 can be glass or a flexible substrate. In this exemplary embodiment, the display device 200 may further include a second substrate 204 covering the first substrate 202, wherein the material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com