Radiating device

A technology for a heat sink and a heat sink, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc. Heat dissipation efficiency, simple manufacturing process, and the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

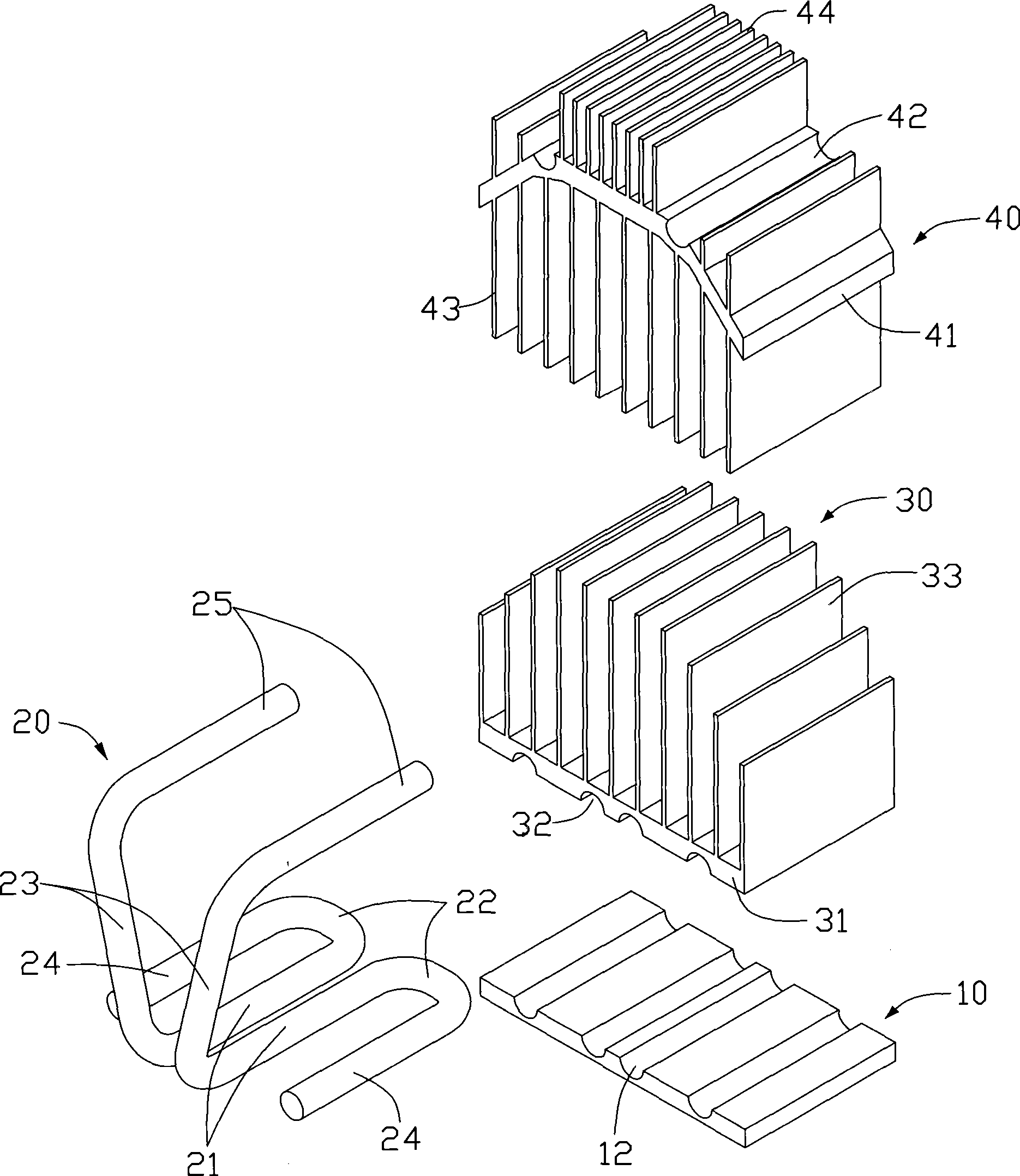

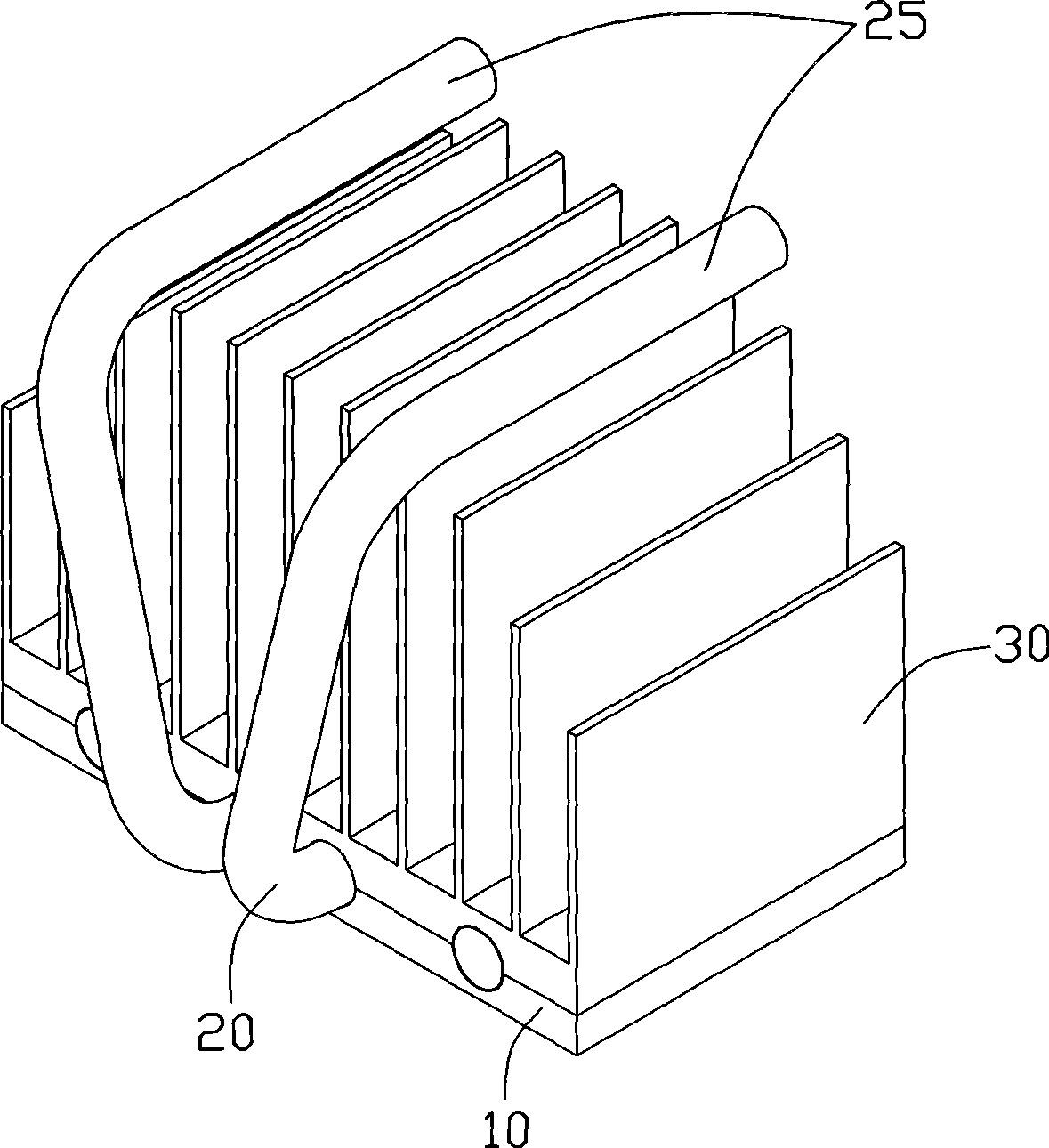

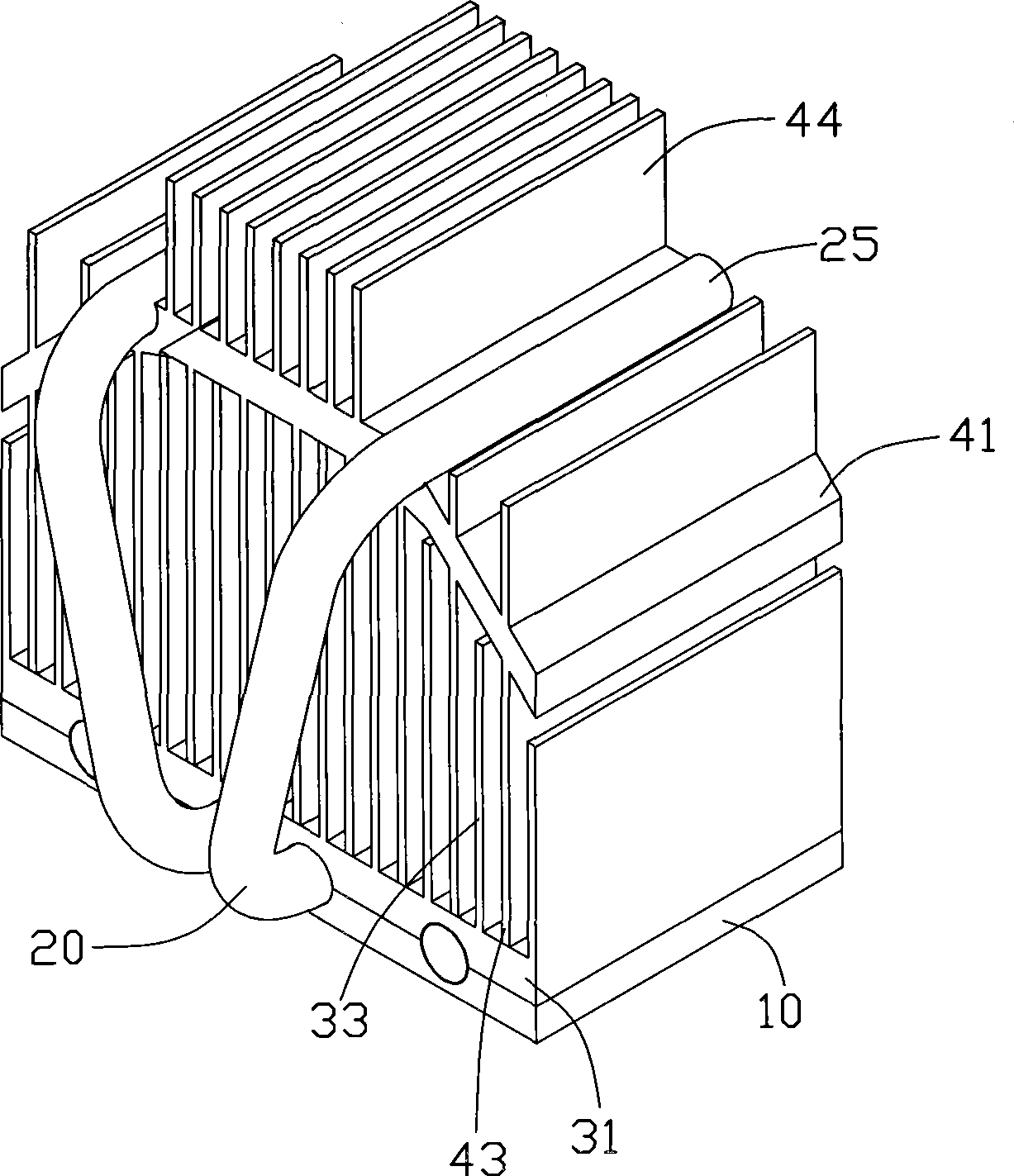

[0012] figure 1 A preferred embodiment of the heat sink of the present invention is shown. The cooling device includes a base 10, a first heat sink 30 placed on the base 10, a second heat sink 40 placed on the first heat sink 30 and a connection base 10, the first heat sink 30 and the second heat sink 30. Two heat pipes 20 of the second radiator 40 . The cooling device is mounted on a circuit board (not shown) for dissipating heat from a heat-generating electronic component (not shown), such as a CPU.

[0013] The base 10 is made of a material with high thermal conductivity, such as copper or aluminum. The base 10 is in the shape of a rectangular block, the bottom of which is used to contact the heating electronic components, thereby absorbing the heat emitted by the heating electronic components. Four semicircular grooves 12 parallel to each other are formed on the top surface of the base 10 . Wherein the two grooves 12 in the middle of the top surface of the base 10 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com