Tire having structure of tire tread including cap tread and base tread

A driving surface and tread technology, applied in the direction of tire tread/tread pattern, special tires, tire parts, etc., can solve the problems of rising proportion of non-petroleum resources and declining grip performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~5

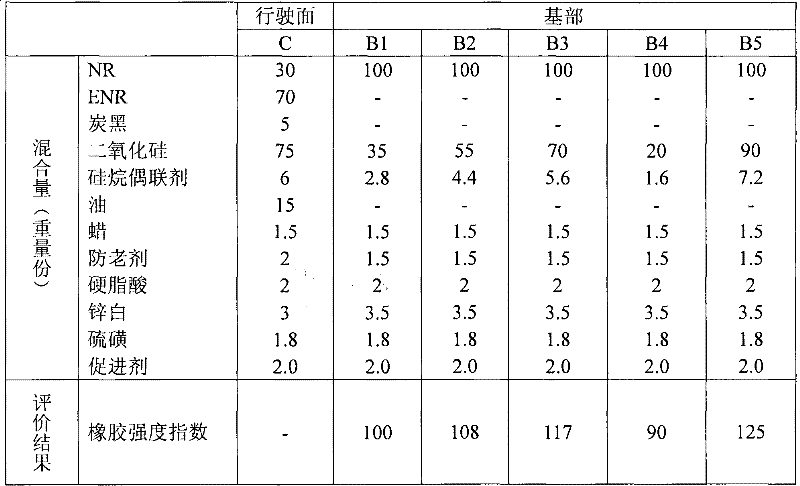

[0062] (Production of vulcanized rubber composition)

[0063] According to the formulation shown in Table 1, using a Banbury internal mixer, under the condition of 130° C., the chemicals except sulfur and vulcanization accelerator were mixed for 2 minutes to obtain a mixed product. Next, sulfur and a vulcanization accelerator were added to the obtained kneaded product, and kneaded at 90° C. for 1.5 minutes using an open mill to prepare an unvulcanized rubber composition. Then, the obtained unvulcanized rubber composition was vulcanized on a flat plate at 170°C for 12 minutes to obtain rubber compositions for base treads (represented as bases in Table 1) B1 to B5 and rubber compositions for cap treads ( In Table 1, it is represented as running surface) C.

[0064] (Preparation of rubber sheet for vulcanization test)

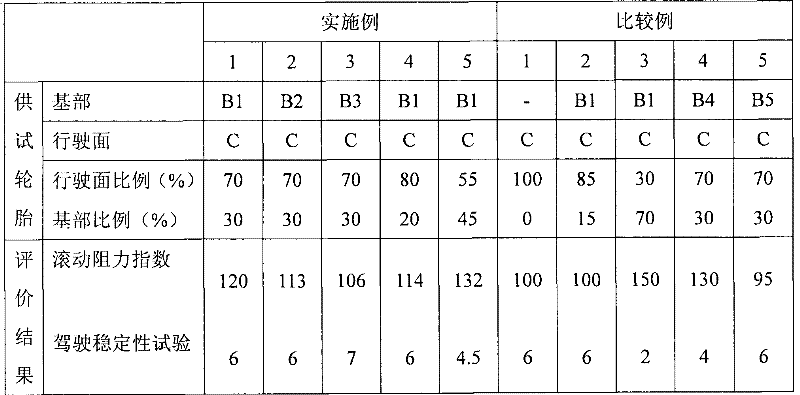

[0065] Using a thickness meter, the ratio of the thickness of the cap tread to the total thickness of the tread (expressed as cap ratio (%) in Table 2) and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com