Preswirl guide device

A guiding device, pre-rotation technology, applied in the components of pumping devices for elastic fluids, non-variable pumps, engine components, etc., can solve the problems of cost and tolerance, reduce reliability, etc., and achieve simplified maintenance operations , the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

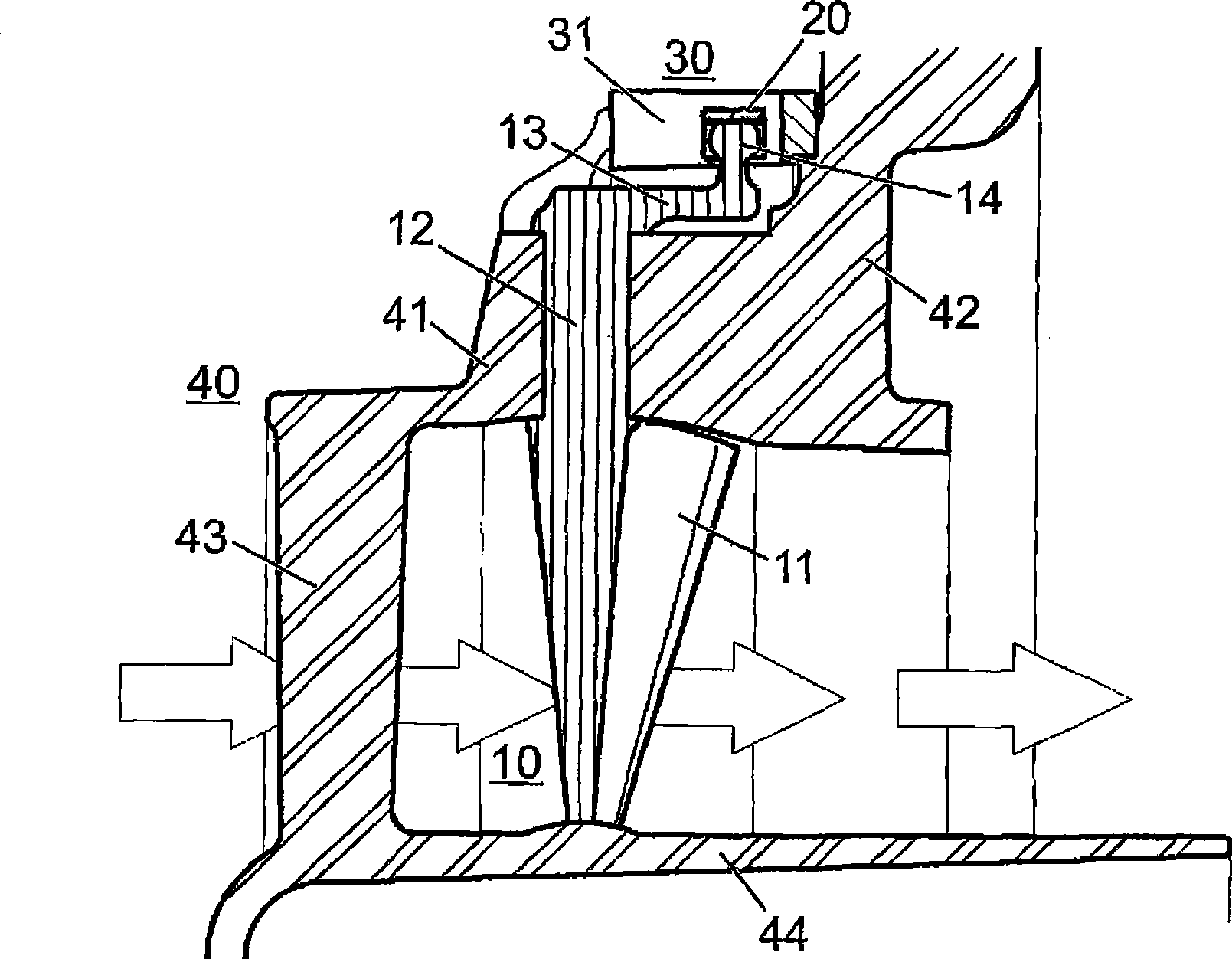

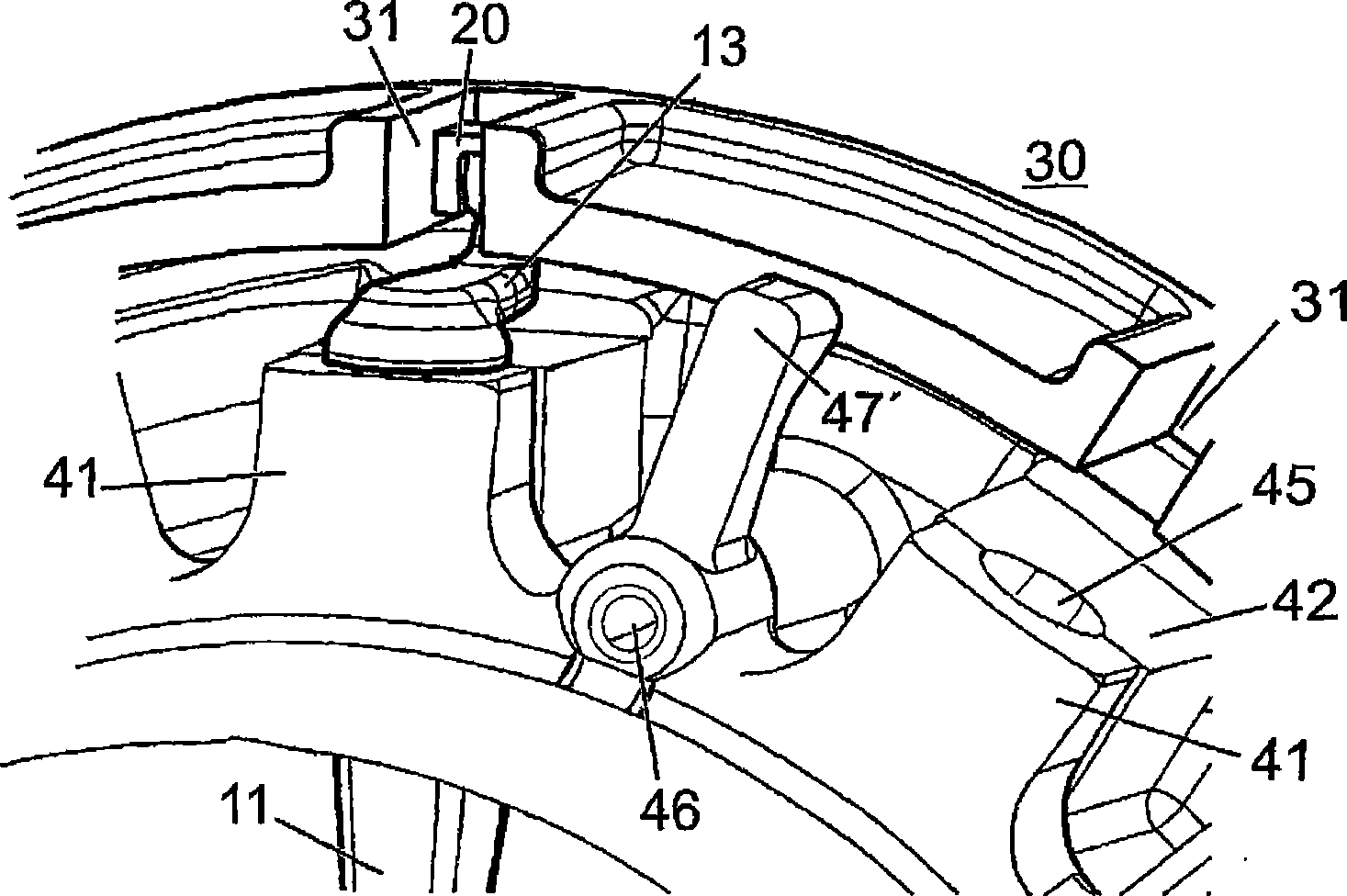

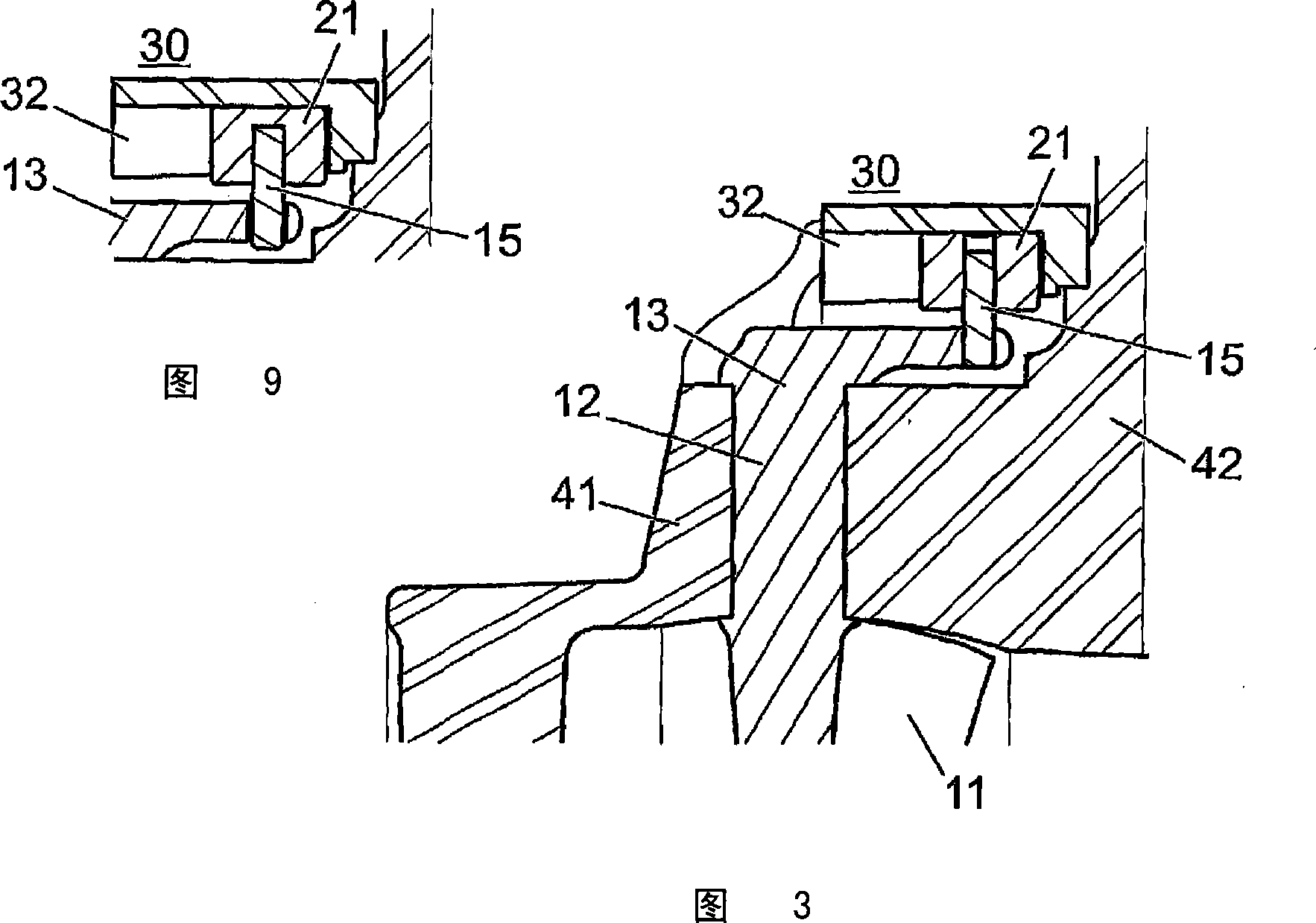

[0024] figure 1 A sectional view of the guide device in the suction region of the compressor is shown. Such compressors are used, as explained at the outset, in exhaust gas turbochargers for increasing the power of internal combustion engines. The arrows in the figures indicate the flow path of the medium to be compressed, usually air or optionally the air-fuel mixture for the combustion process in the internal combustion engine. Furthermore, such guides can be used in every type of compressor, for example in industrial compressors driven by electric motors.

[0025] The guide device comprises a plurality of guide vanes 10 arranged oriented in the radial direction with respect to the compressor axis. Each guide vane comprises, in addition to a vane profile 11 protruding into the flow channel, a vane shank 12 with which the vane profile is rotatably mounted in the housing. The blade profile can be rotated around the axis of the blade shaft via the adjusting rod 13 . For dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com