Position sensor with variable direction of magnetization and method of production

A magnetization direction, motion sensor technology, applied in the direction of conversion sensor output, instruments, measuring devices, etc., can solve the problem of increasing the cost of the sensor, and achieve the effect of simple structure, beneficial durability, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

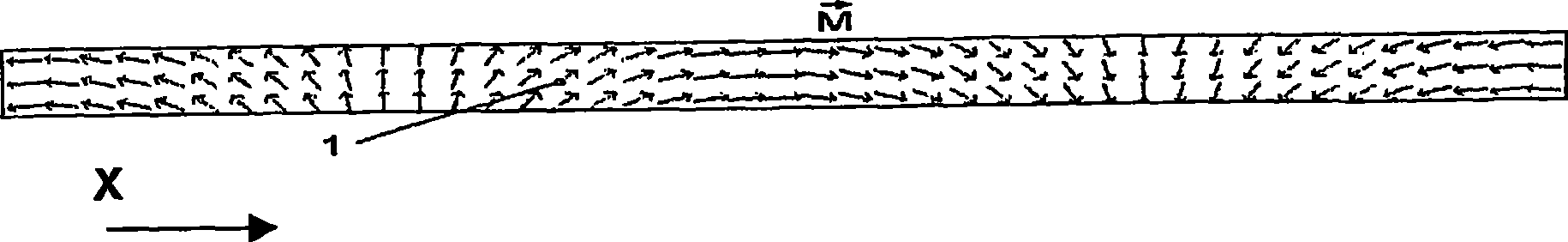

[0099] figure 1 Magnet (1) is shown with vector The magnetization represented by , the direction of this vector varies linearly along the length of the magnet in the plane defined by the direction of motion X and the direction perpendicular to the direction of motion (normal). It can be seen that the lines of force in the magnetic field inside the magnet are non-collinear, which constitutes a basic principle of the present invention.

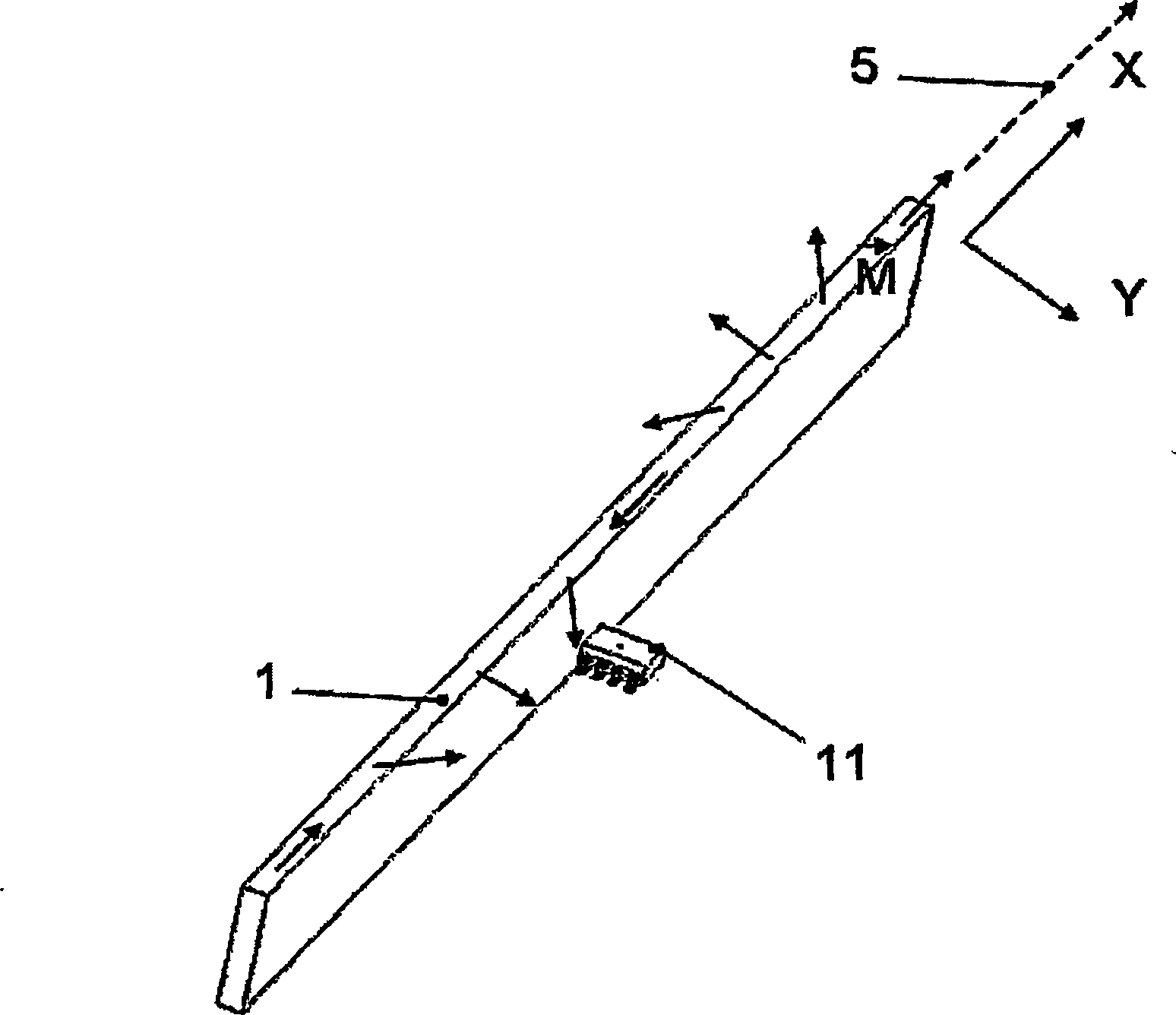

[0100] figure 2 The minimal structure of the sensor is shown: a magnet (1) moving relative to the probe (11) along a direction of motion (5) defined by axis X, axis Y being defined as normal to the surface of the magnet.

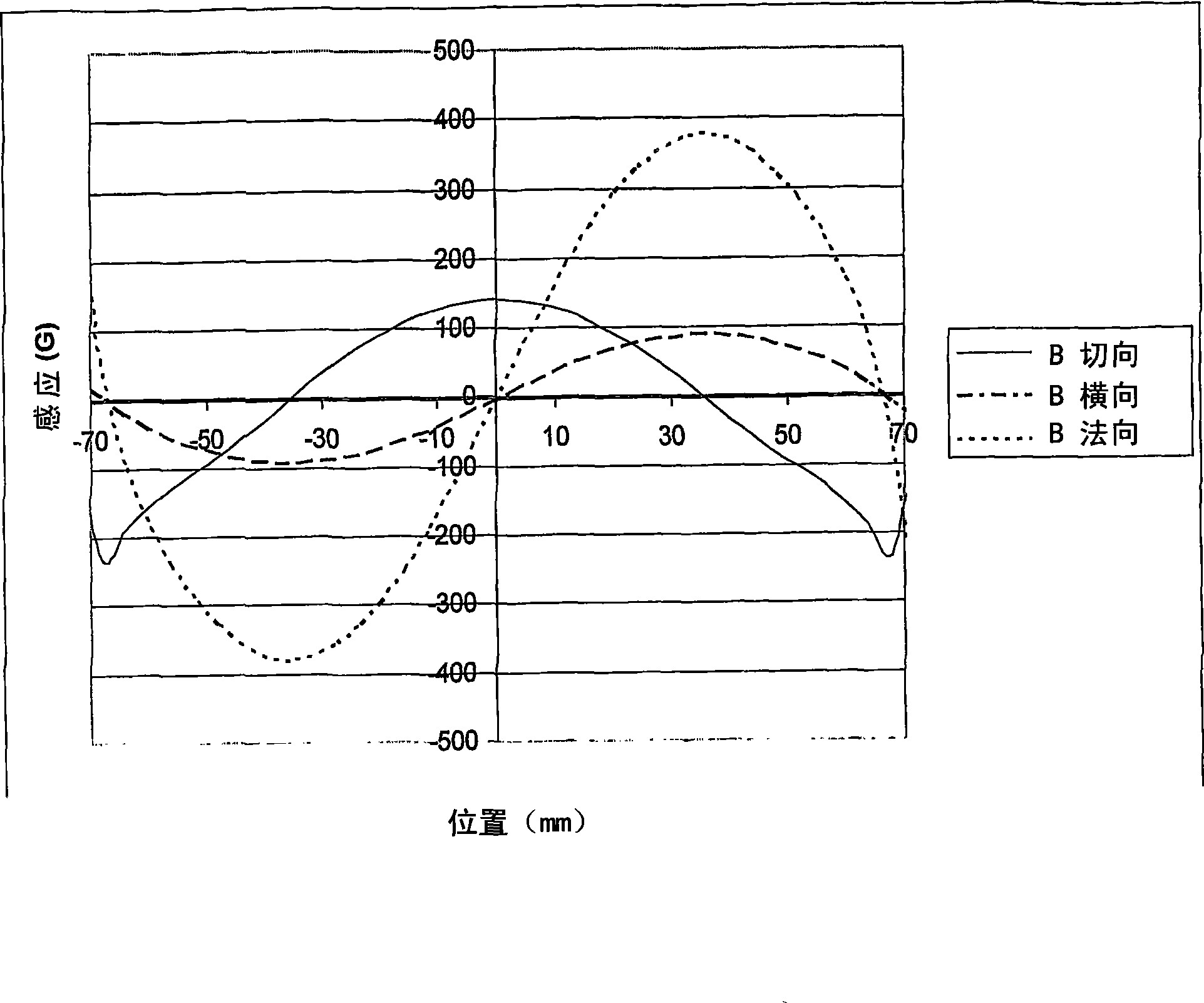

[0101] image 3 The tangential, normal and transverse components arising at a point near the magnet (1) are shown. Components Y and Z have the same phase, while the phase of component X is shifted by a quarter period.

[0102] Figure 4 The magnet (1) is shown mounted on a ferromagnetic yoke (2) that moves relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com