Structure, forming method of structure, structure forming device, structure color, diffraction light reading method, and truth/false discriminating method

A technology of structural body and structural color, applied in the direction of diffraction grating, optics, optical elements, etc., can solve the problems of few practical examples and difficulty of structural color, achieve the effect of simple material composition and avoid cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

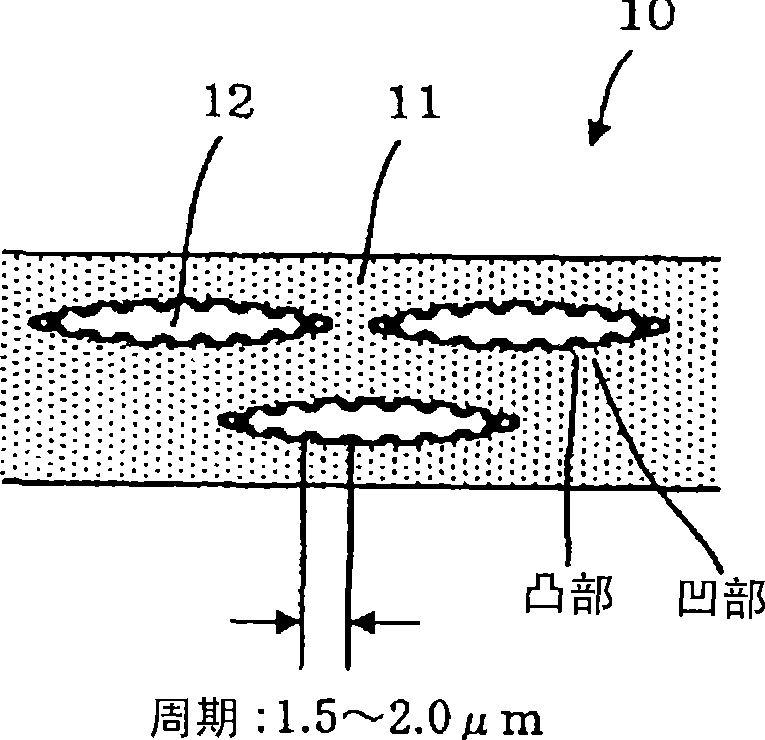

[0277] The Q-switched pulsed YAG laser beam is split into multiple beams by a transmissive diffractive optical element. Each beam was passed through a synthetic quartz plano-convex lens with a focal length of 200 mm placed at a distance of 200 mm from the diffractive optical element. At the position where the passing beam is focused, the mask shields and interferes with the unnecessary beam, and allows only the required beam to pass. The passing beam was condensed by a synthetic quartz plano-convex lens with a focal length of 100 mm, and the beams were crossed and interfered. A 2-axis extended PET sheet was irradiated in the region of interference. First, irradiation was performed at a laser wavelength of 355 nm (transmittance of the PET plate: 83%).

[0278] Next, irradiation was performed by switching the wavelength to 266 nm (the transmittance: 0.3%). The 2D grating period of the diffractive optical element is 6 μm. Specifications of pulsed YAG laser: pulse width is 5ns...

Embodiment 2

[0286] As in Example 1, only the biaxially stretched PET sheet was irradiated with laser light having a wavelength of 266 nm. Structural colors of the formed 2-dimensional structures were observed.

[0287] If ester oil (CAS-Nr: 195371-10-9) with a refractive index of 1.518 (CAS-Nr: 195371-10-9), which is similar to the refractive index of stretched PET sheets of 1.64, is applied to the periodic structure, the structural color is not observed, but the original transparent stretch is observed. PET board.

[0288] (comparison with comparative example)

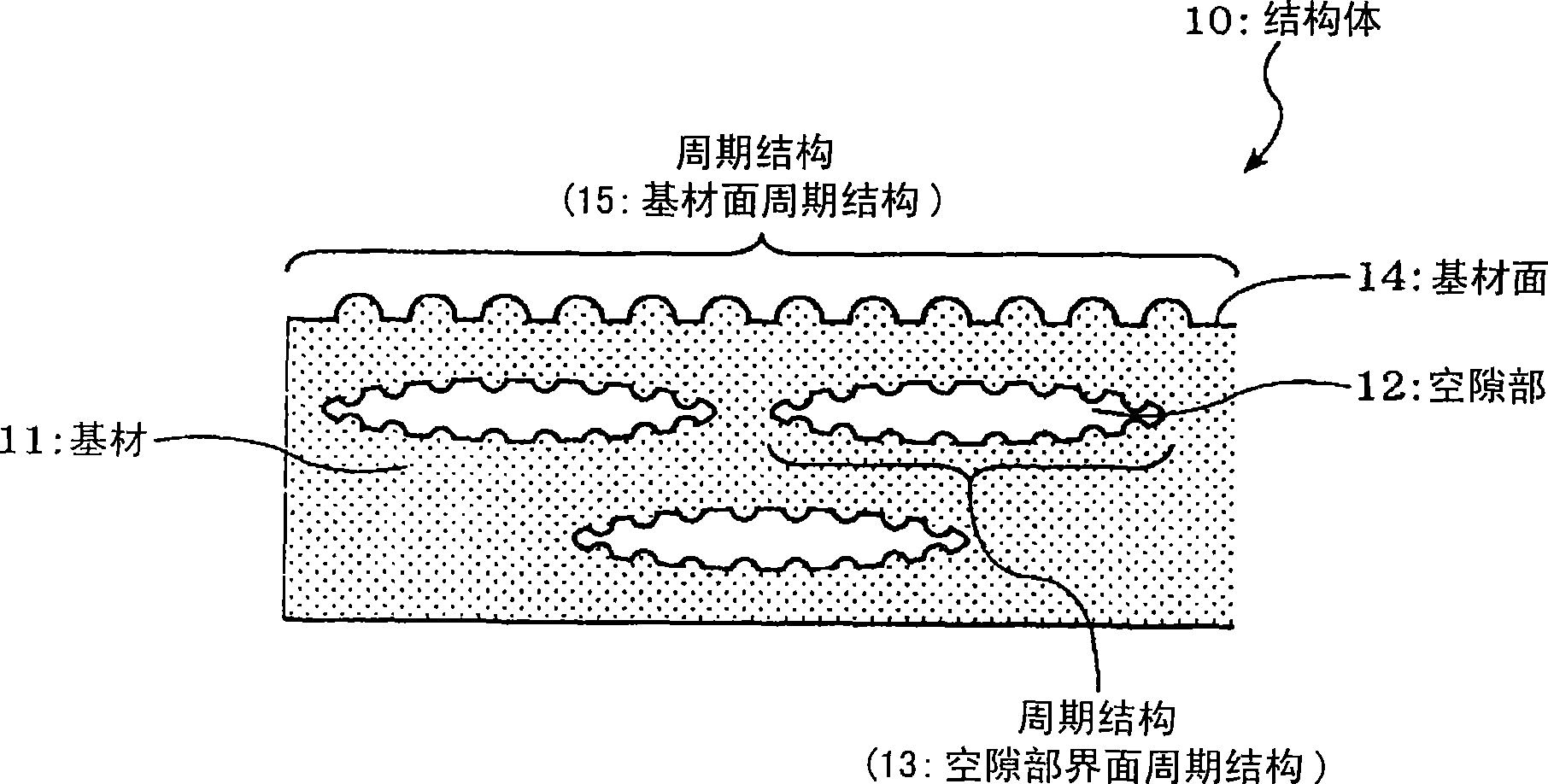

[0289] Second, refer to Figure 20 ~ Figure 22 A comparison between the structured body of the present embodiment and the comparative example will be described.

[0290] (Comparison of Voids and Cavities)

[0291] The technique of forming a plurality of microscopic cavities inside a substance to develop color is JP2004-359344 A "Plastic Packaging and Decorating Method" (hereinafter referred to as Comparative Example 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com