Composite crystallizer

A crystallizer and duplex technology, which is applied in the field of metal casting, can solve the problems of insufficient cooling and large slab resistance, and achieve the effects of improving cooling capacity, reducing motion resistance and reducing accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

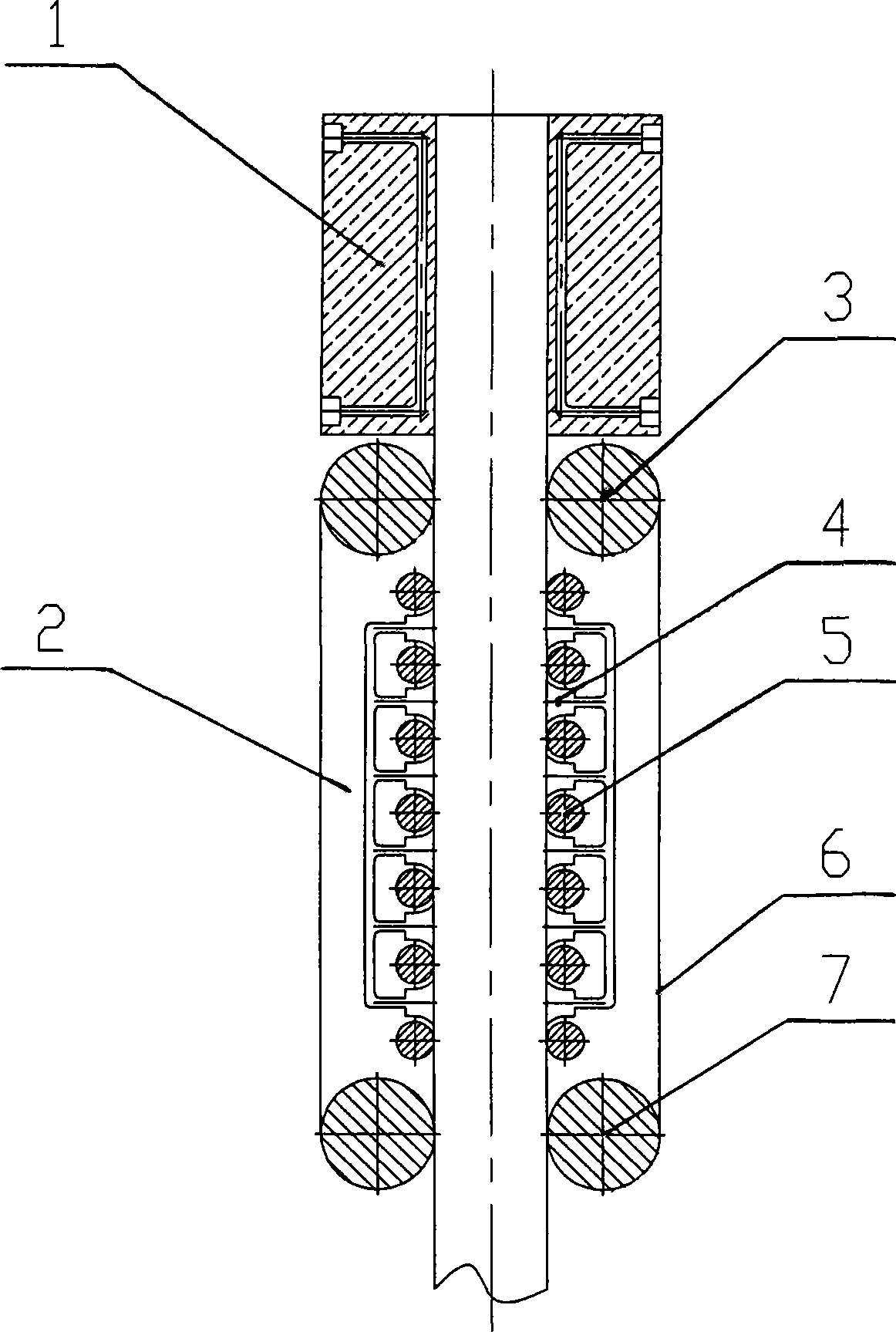

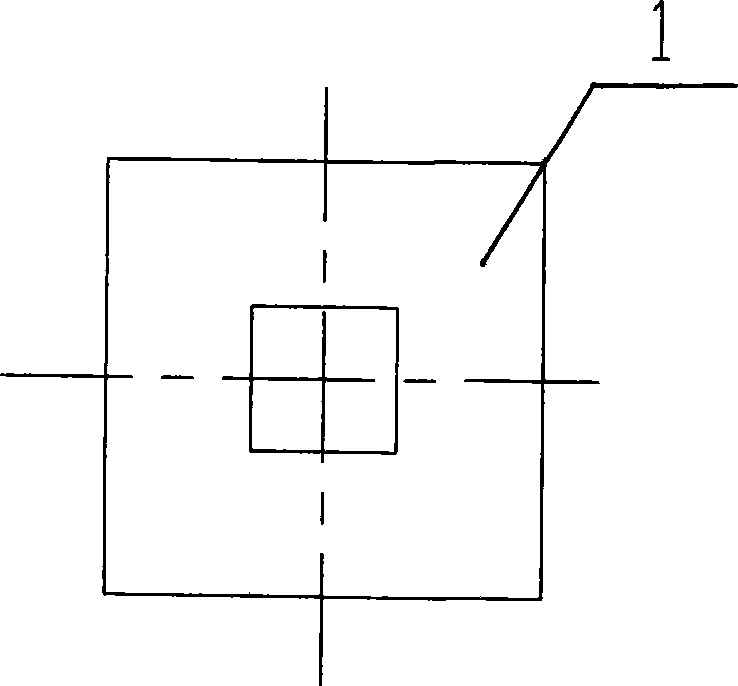

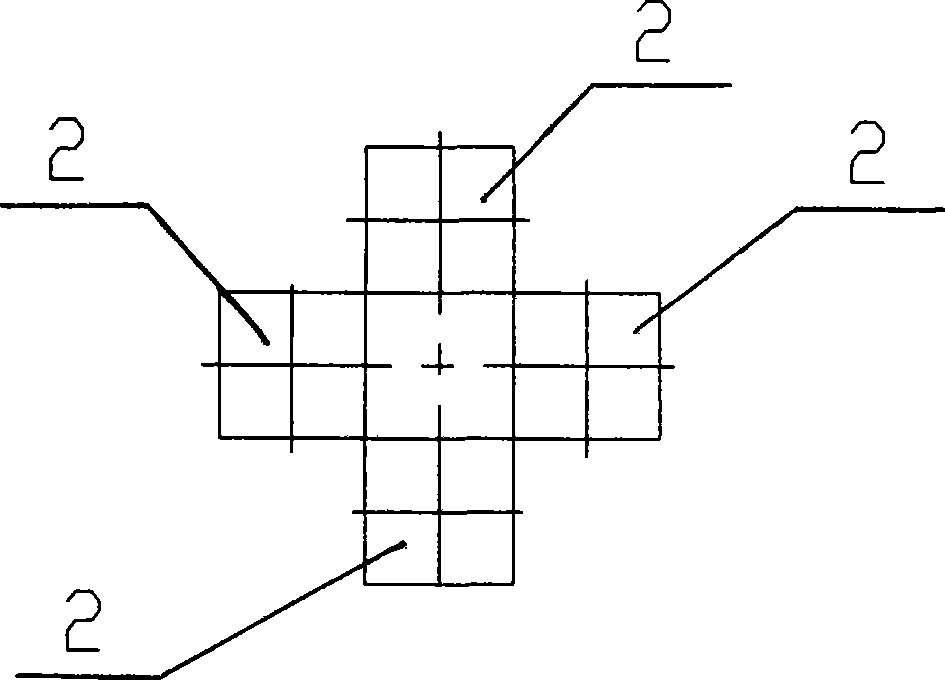

[0012] see Figure 1 to Figure 3 , the present invention is a kind of compound crystallizer, and it is made up of upper crystallizer 1 and lower crystallizer 2 two parts. The upper crystallizer 1 is a traditional sliding crystallizer, and the lower crystallizer 2 is a synchronous circulating cooling belt device. There can be more than two lower crystallizers 2, and two synchronous circulating cooling belt devices can be arranged as a group facing each other.

[0013] The lower crystallizer 2 is composed of more than two cooling belts 6, driven rollers 3, cooling devices 4, supporting rollers 5 and driving rollers 7, the driven rollers 3 and driving rollers 7 are respectively located at two ends of the cooling belt 6, and the supporting rollers 5 And the cooling device 4 is arranged between the driven roller 3 and the driving roller 7 , and each cooling belt 6 surrounds the periphery of the driven roller 3 , the cooling device 4 , the supporting roller 5 and the driving roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com