Regulating transmission fluid and engine coolant temperatures in a motor vehicle

A technology for engine cooling, transmission oil, applied in the field of temperature devices, which can solve the problems of inability to cool heavy-duty applications, reduced heater performance, compromised passenger compartment heater performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

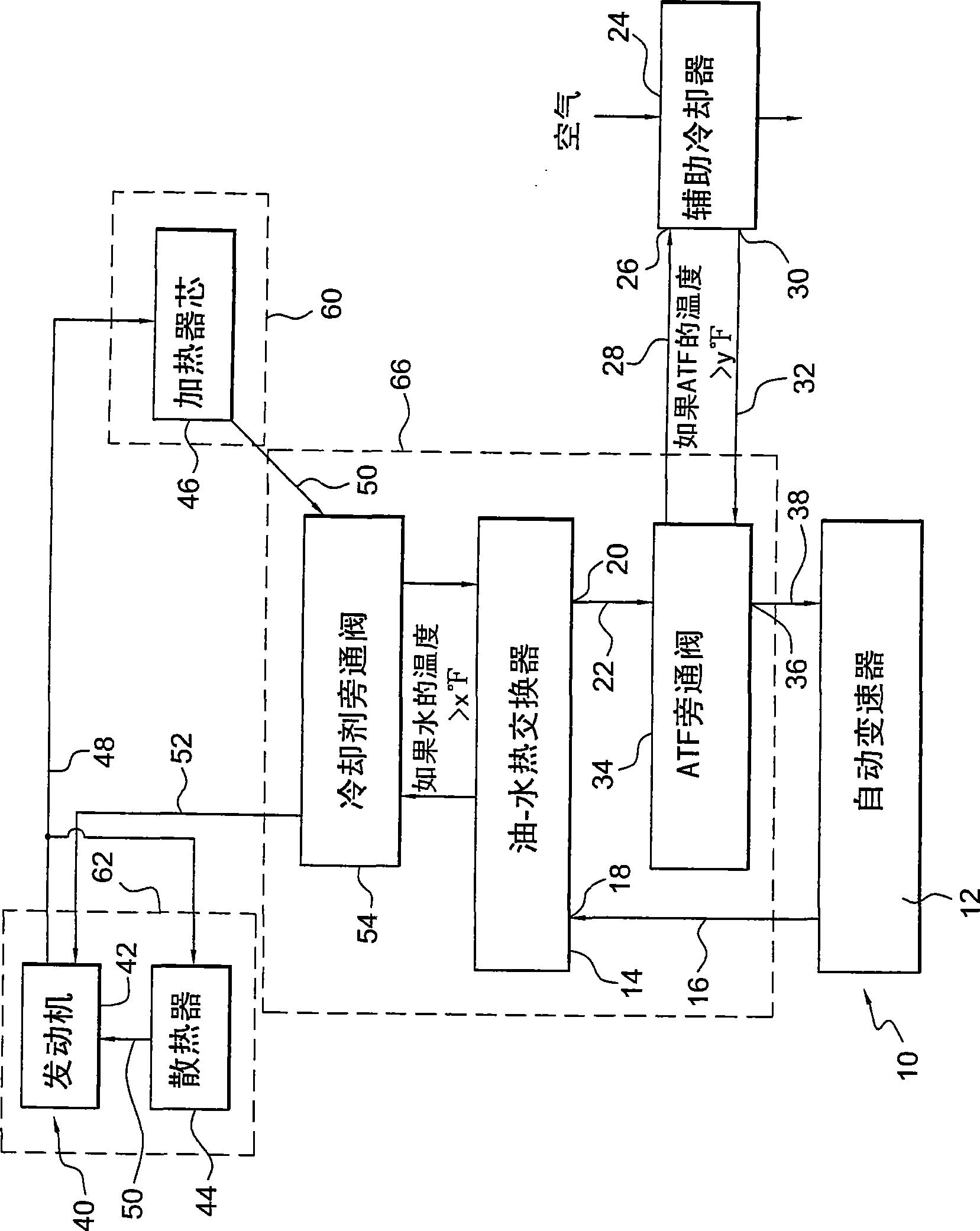

[0014] The automatic transmission 10 includes an oil pan 12 as a transmission oil source, from which transmission oil is supplied to an inlet side of a transmission pump (not shown), where the transmission oil is delivered from an oil passage of the transmission after lubrication , and remove heat from clutches, bearings, shafts, gears and other transmission components.

[0015] A first heat exchanger or oil-to-water heat exchanger 14 in communication with transmission oil source 12 via oil passage 16 is adapted to convey engine coolant and transfer heat between the engine coolant and transmission oil. The heat exchanger 14 includes a first inlet 18 through which transmission oil enters the heat exchanger 14 from the oil passage 16 and a first outlet 20 through which transmission oil exits the heat exchanger and enters the oil passage 22 .

[0016] The second heat exchanger auxiliary cooler 24 includes passages through which ambient air can flow, transferring heat between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com