Automatic transport mechanism of double knot drinking straw packing machine

An automatic conveying and packaging machine technology, applied in the direction of conveyors, conveyor objects, packaging, etc., can solve the problems of decreased sanitation factors, labor tension in management, and many operators, so as to improve hygiene indicators, labor tension, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

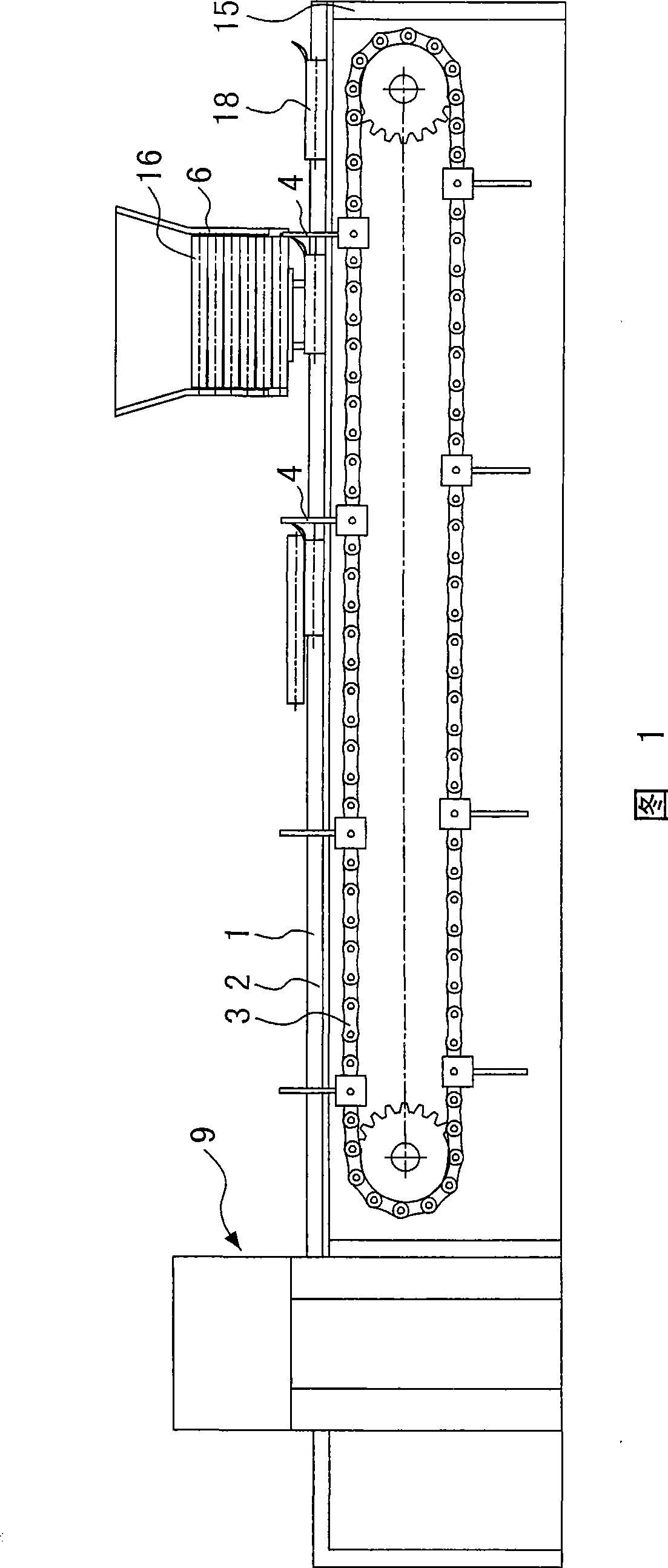

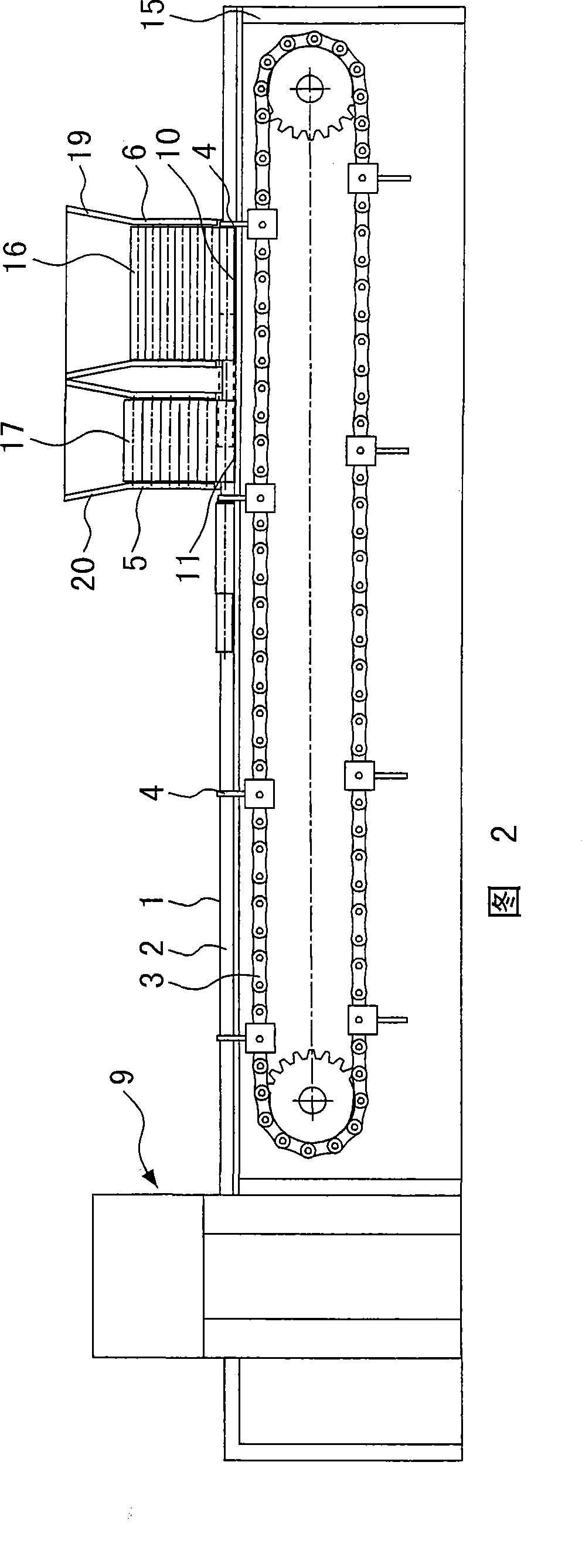

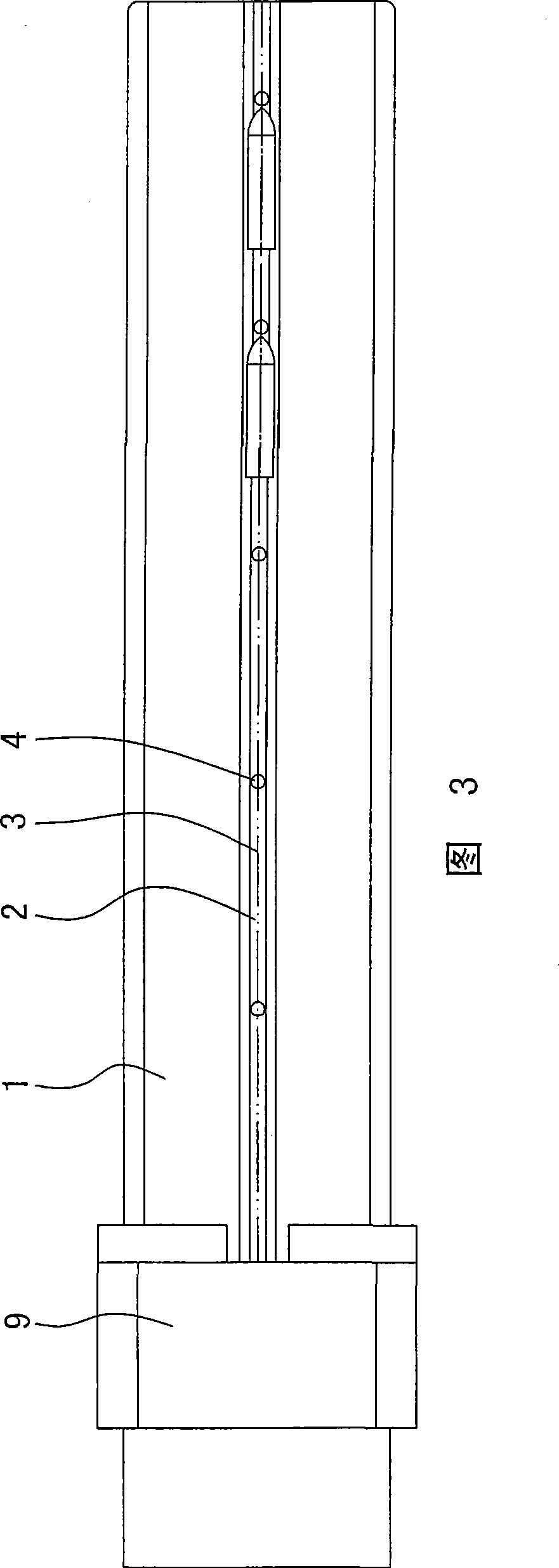

[0012] The present invention relates to an automatic conveying mechanism of a double-section drinking straw packaging machine, as shown in Figures 1-5, comprising a frame 15, on which a workbench 1 with a conveying trough 2 in the middle is installed, and a conveying chain is installed right below the conveying trough 3. Equidistant push rods 4 are installed in the conveying chain, and the heads of the push rods extend above the conveying trough. The workbench 1 is connected to the film packaging mechanism 9. It is characterized in that the second straw hopper 6 or the first straw hopper is installed above the workbench 1. Suction pipe hopper 5 and the second suction pipe hopper 6, the lower mouth of suction pipe hopper is aimed at delivery tank 2, puts suction pipe 16,17 in the suction pipe hopper. One or two hoppers 5,6 for putting straws are installed above the workbench, if one of them is a straw 18 with a spoon, as shown in Figure 1, at first the straw with a spoon (becaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com