Cable system construction method of spatial self-anchored rope-suspension bridge

A self-anchored suspension bridge and construction method technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems such as excessive angle deviation of drum wires and cable clip lugs, reduce safety factor, etc., and achieve a simple construction method. , to ensure the effect of void ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and examples.

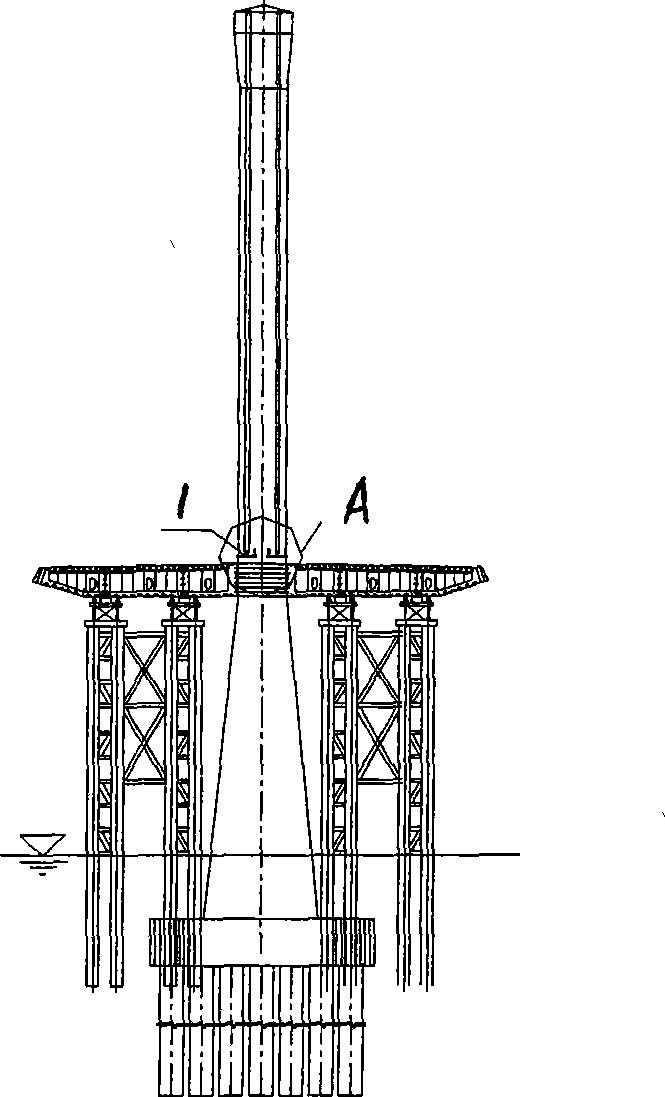

[0023] 1. Set up the catwalk on the vertical plane

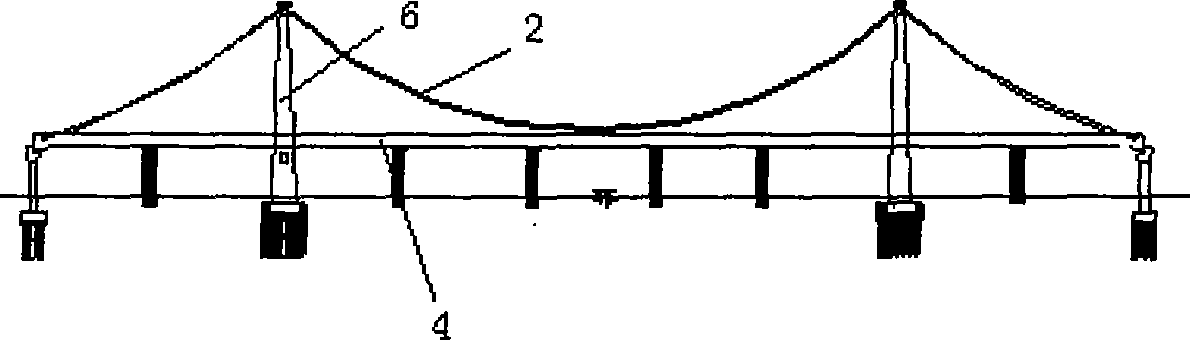

[0024] Such as Figure 10 with Figure 11 As shown, the catwalk 1 is composed of catwalk load-bearing cables, beams, handrail cables, surface nets, horizontal wind-resistant stability cables 7, anchor adjustment systems, and the like. Catwalk load-bearing cable 1 can use three-span separation structure. A combined catwalk is set up on both sides. Since the mid-span main cable needs to undergo a space conversion process, two independent catwalks are used for the mid-span catwalk.

[0025] 2. Weaving cables on the vertical plane

[0026] The main cable 2 is set above the catwalk 1, and the main cable unit strands adopt a relatively mature vertical plane erection technology, which is divided into two types: general strand erection and reference strand erection. The main construction steps are: cable s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com