Method for processing soft land base/tail slag/lake silt by supercharging preconsolidation at vacuum

A soft soil foundation and tailings slag technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as poor stability, stepping on, and large safety hazards, and achieves shortened strengthening time, low cost, and solid The effect of increased knot depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

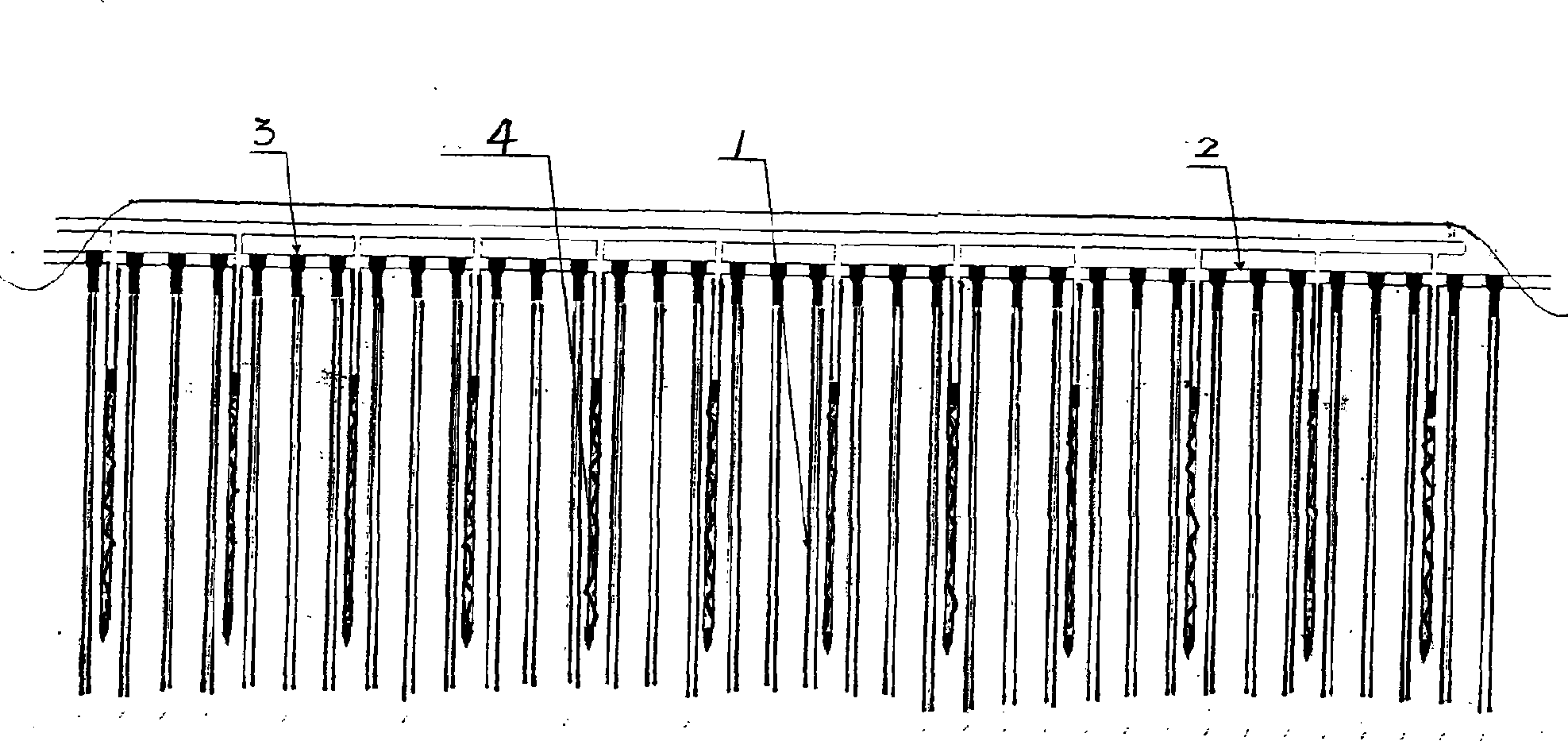

[0012] Embodiment 1, the method for pressurized vacuum preloading consolidation treatment of soft soil foundation / tailings slag / lake silt, vacuumize the interior of several rows of plastic drainage boards arranged horizontally in the soil body / slag / silt, and simultaneously vacuum the plastic drainage boards Part of the soil / slag / silt in between is evenly pressurized.

[0013] That is to say, the top of each plastic drainage board 1 is directly connected to the vacuum tube 2. When the plastic drainage board 1 is connected to the vacuum tube 2, a hand joint 3 is used. The hand joint is composed of two parts. The lower end is in the shape of a hollow box. Several evenly distributed convex tubes are arranged on the top.

[0014] In the soil / slag / silt between the plastic drainage boards 1, the water-permeable booster pipes 4 are evenly distributed. The water-permeable booster pipes for horizontal wells are preferably composed of several sections of water-permeable hoses connected i...

Embodiment 2

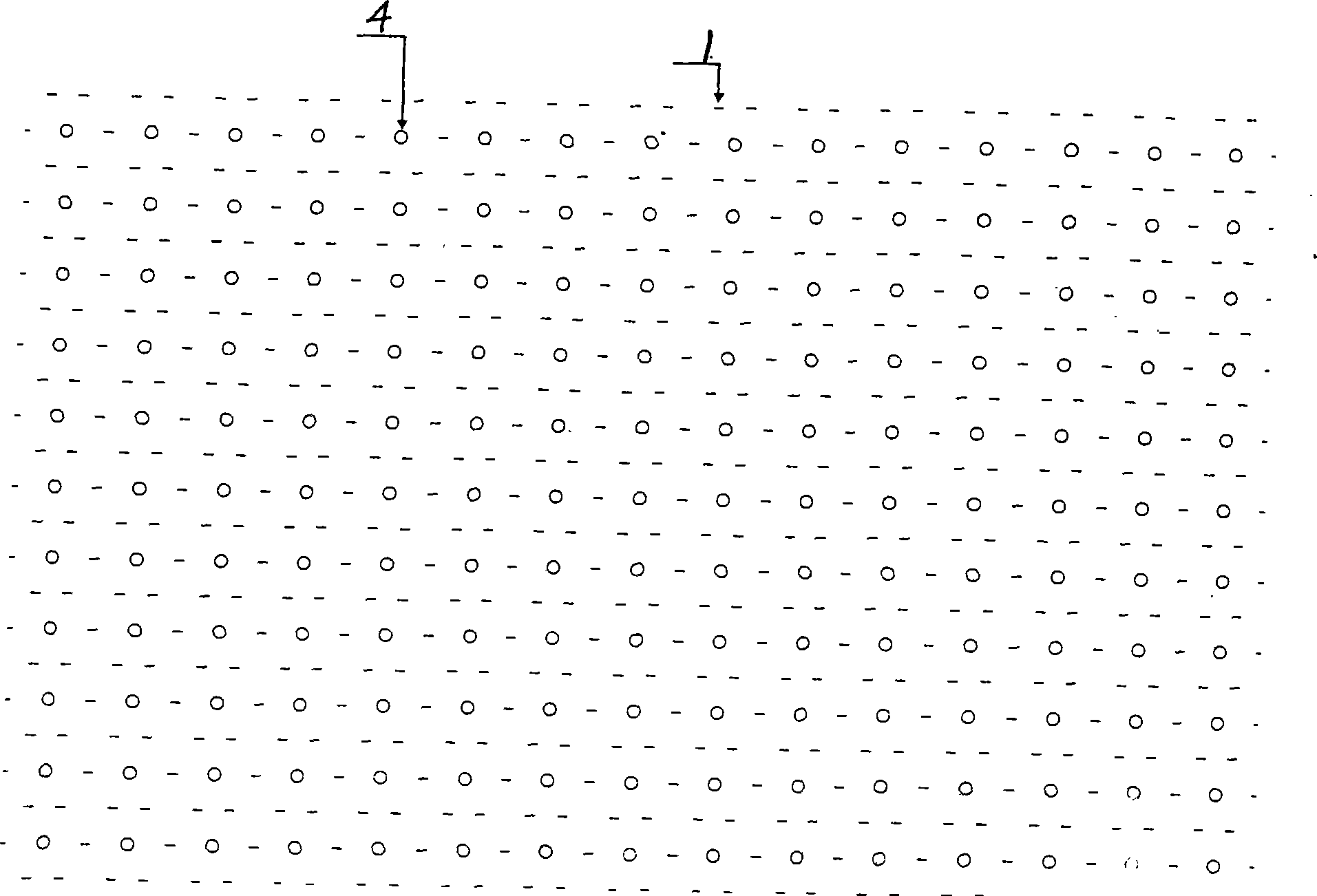

[0015] Embodiment 2, with reference to Example 1, each row of plastic drainage boards 1 placed horizontally is arranged in a regular hexagon, and the distance between each plastic drainage board is designed to be 0.8-1.5m (determined according to design requirements), and each regular hexagonal A permeable booster pipe 4 is placed in the center.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com