Longitudinal displacement measuring method for railway rail by employing laser measurement technology

A technology of laser measurement and longitudinal displacement, applied in the direction of using optical devices, measuring devices, instruments, etc., to achieve the effects of convenient detection, simple operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

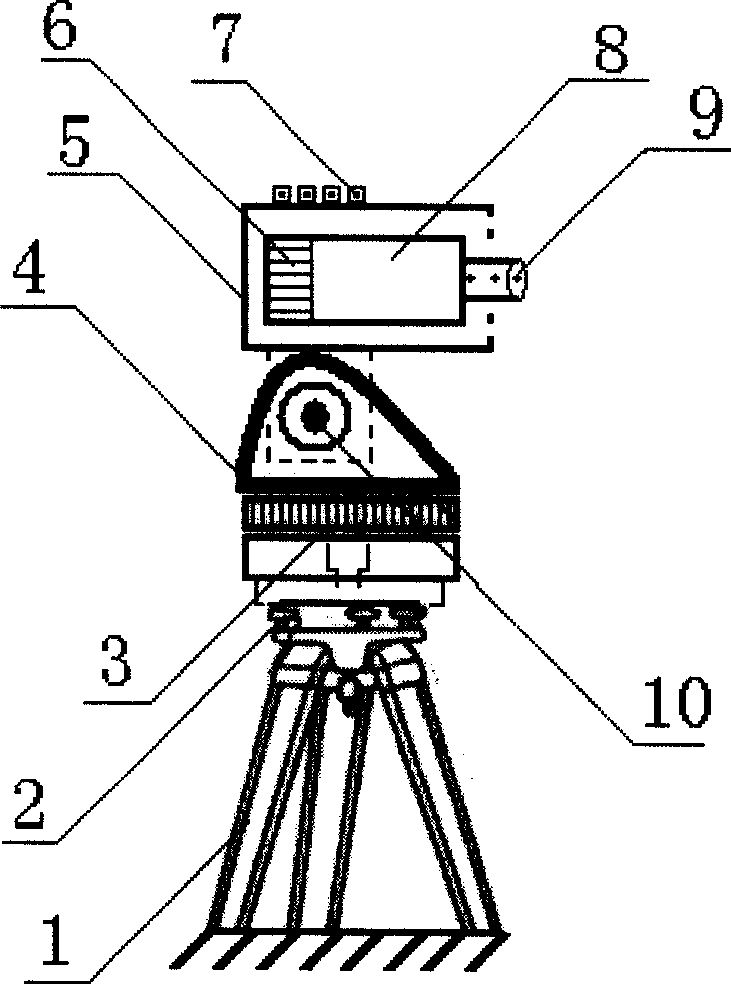

[0025] figure 1 Middle: The laser emitter consists of a fixed bracket 4, a housing 5, a control and power supply unit 6, an operation keyboard 7, a laser 8, a lens 9, and a stepping motor 10; 3 on the bracket 1.

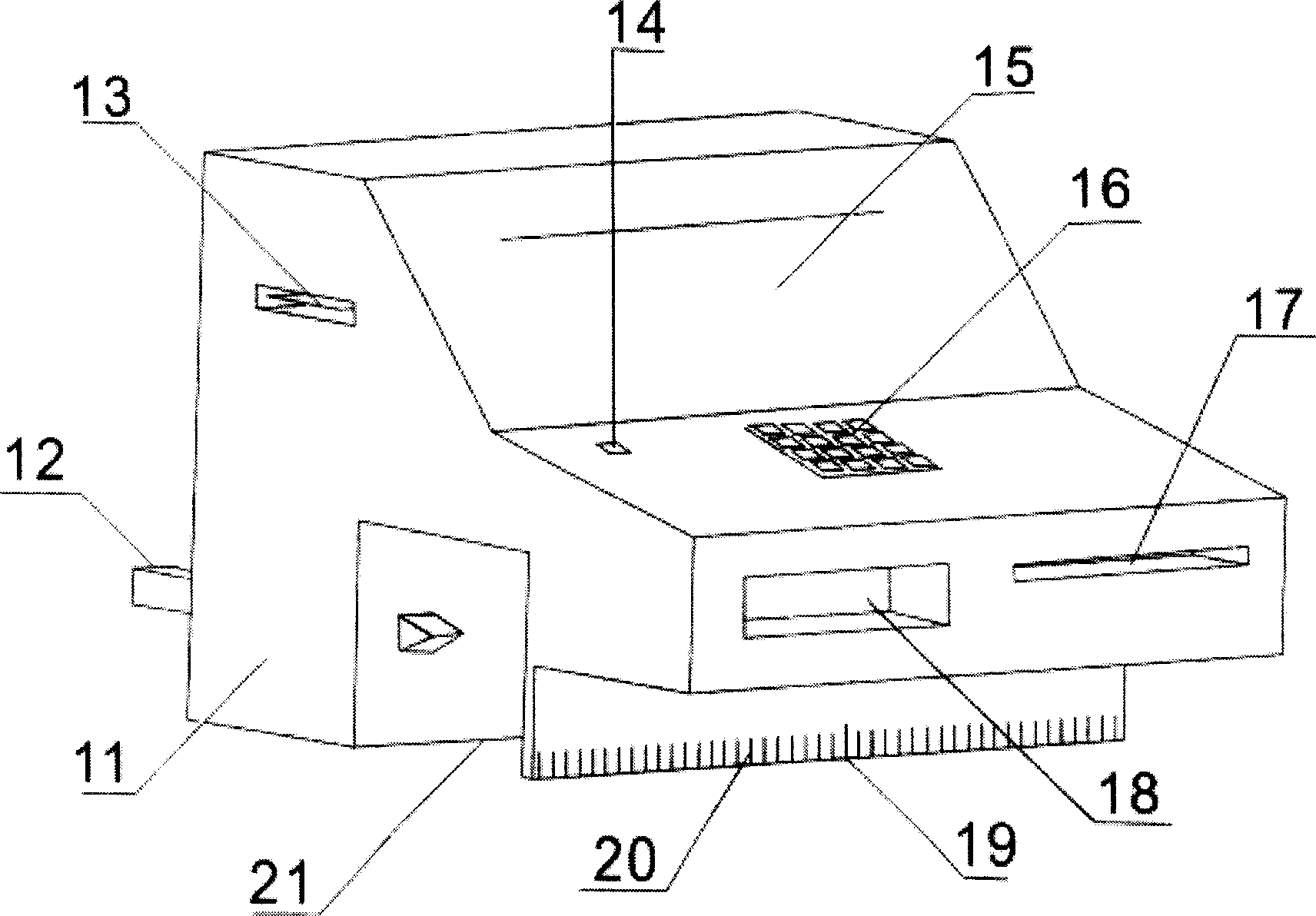

[0026] figure 2 Middle: housing 11, rail positioning pin 12, IC card storage port 13, power switch 14, LCD display 15, operating keyboard 16, light detection slot 17, light positioning display 18, positioning scale 19, capacitance scale 20 , The guide rail groove 21 forms a laser detector and a microprocessor control system.

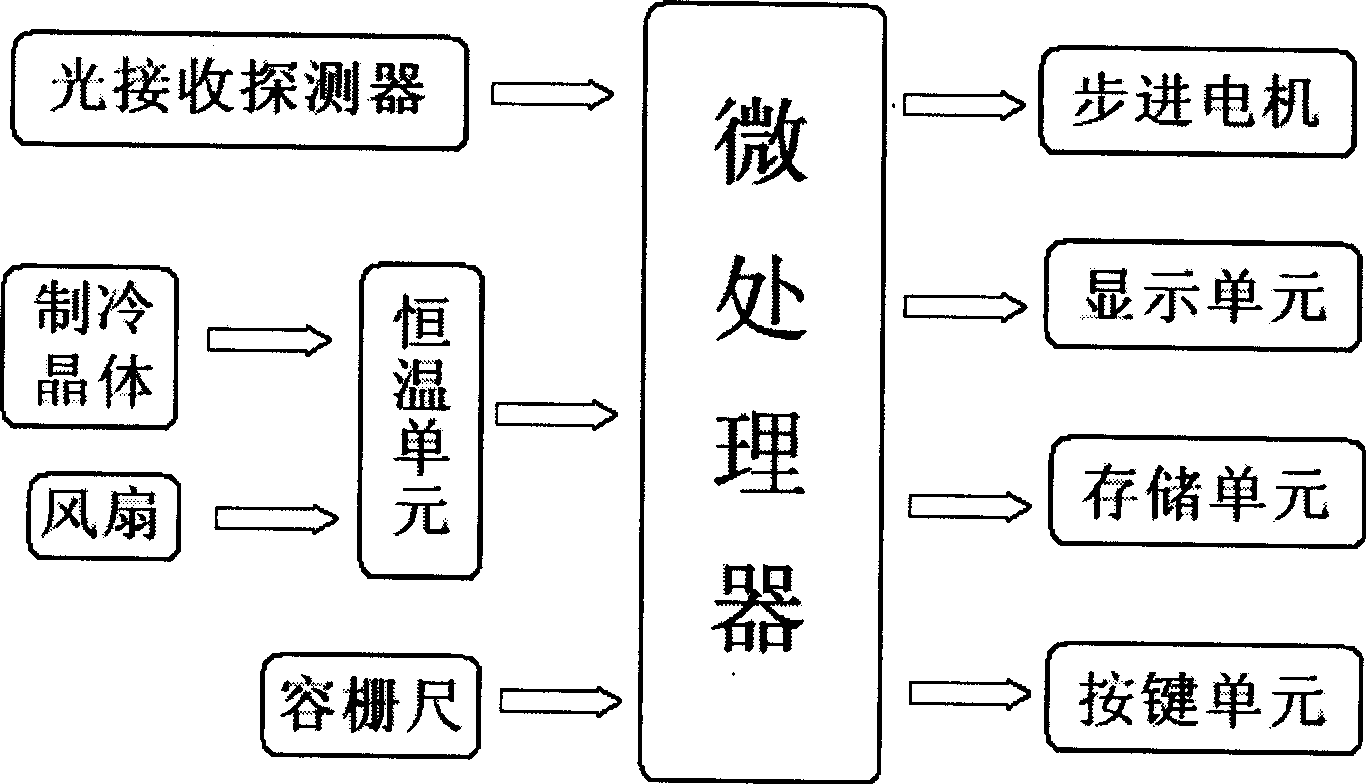

[0027] image 3 Middle: The microprocessor control system includes a microprocessor, a laser detector, a constant temperature unit, a capacitive scale, a stepping motor, a display unit, a storage unit, and a key unit. The constant temperature unit is composed of a cooling crystal and a fan.

[0028] Figure 4 Middle: The traditional subgrade test platform is composed of rail beams 22, tracks 23, reference points 24, test platforms 25, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com