Piezoresistive micro-cantilever beam sensor based on suture stress concentration and manufacture method

A technology of micro-cantilever beam and stress concentration, which is applied in the direction of biological testing, material inspection products, etc., to achieve large bending stress and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but is not limited to the examples.

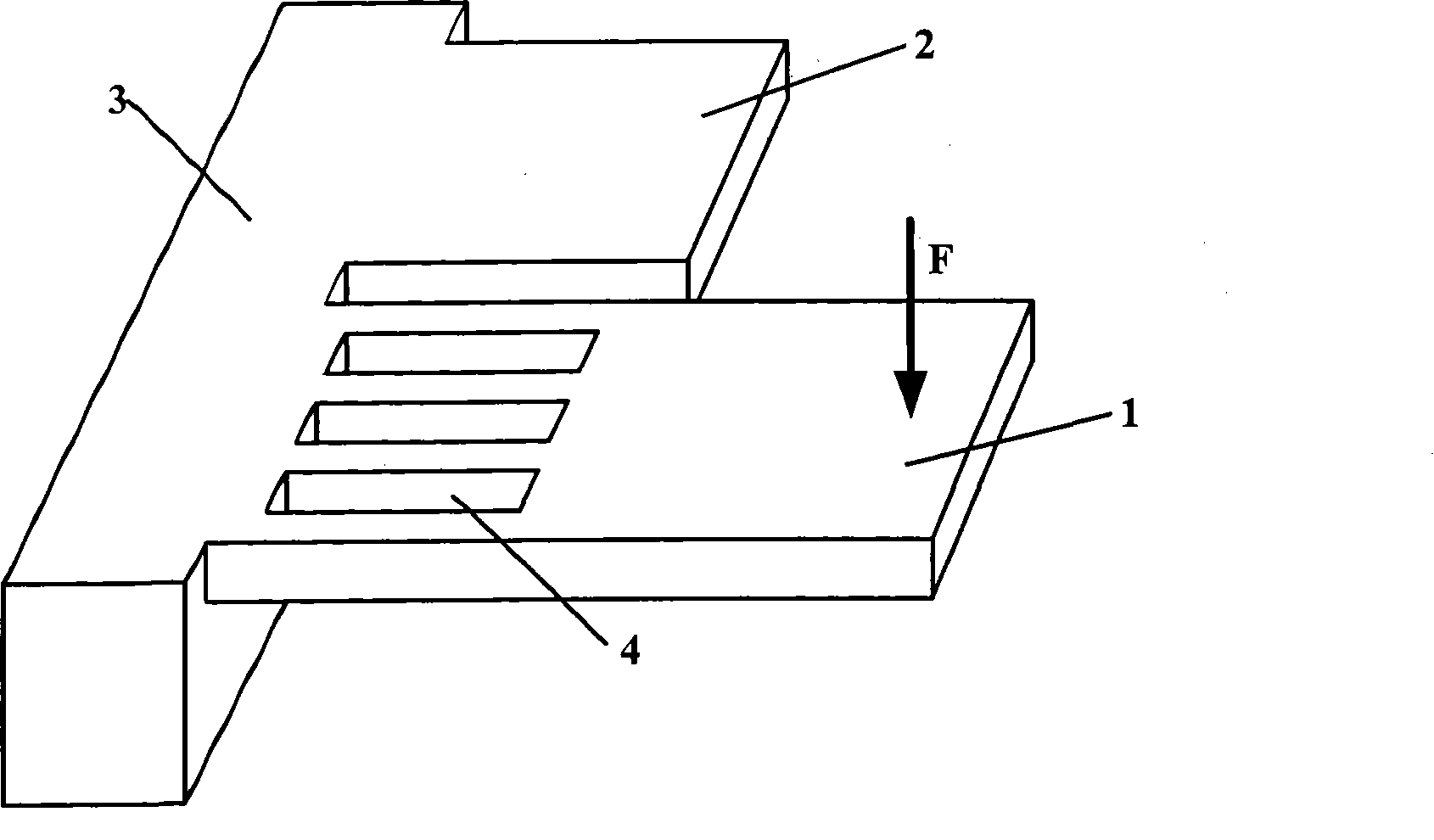

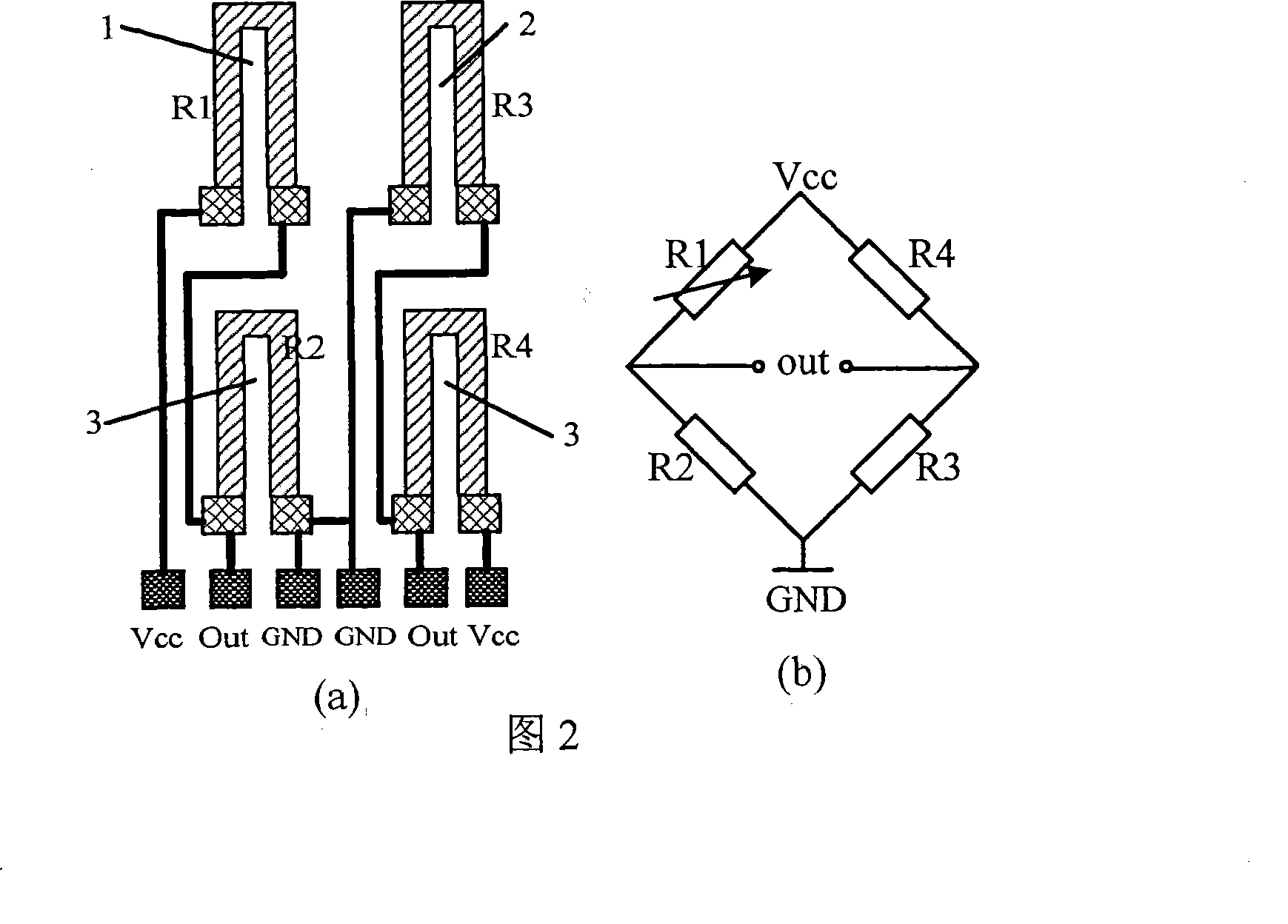

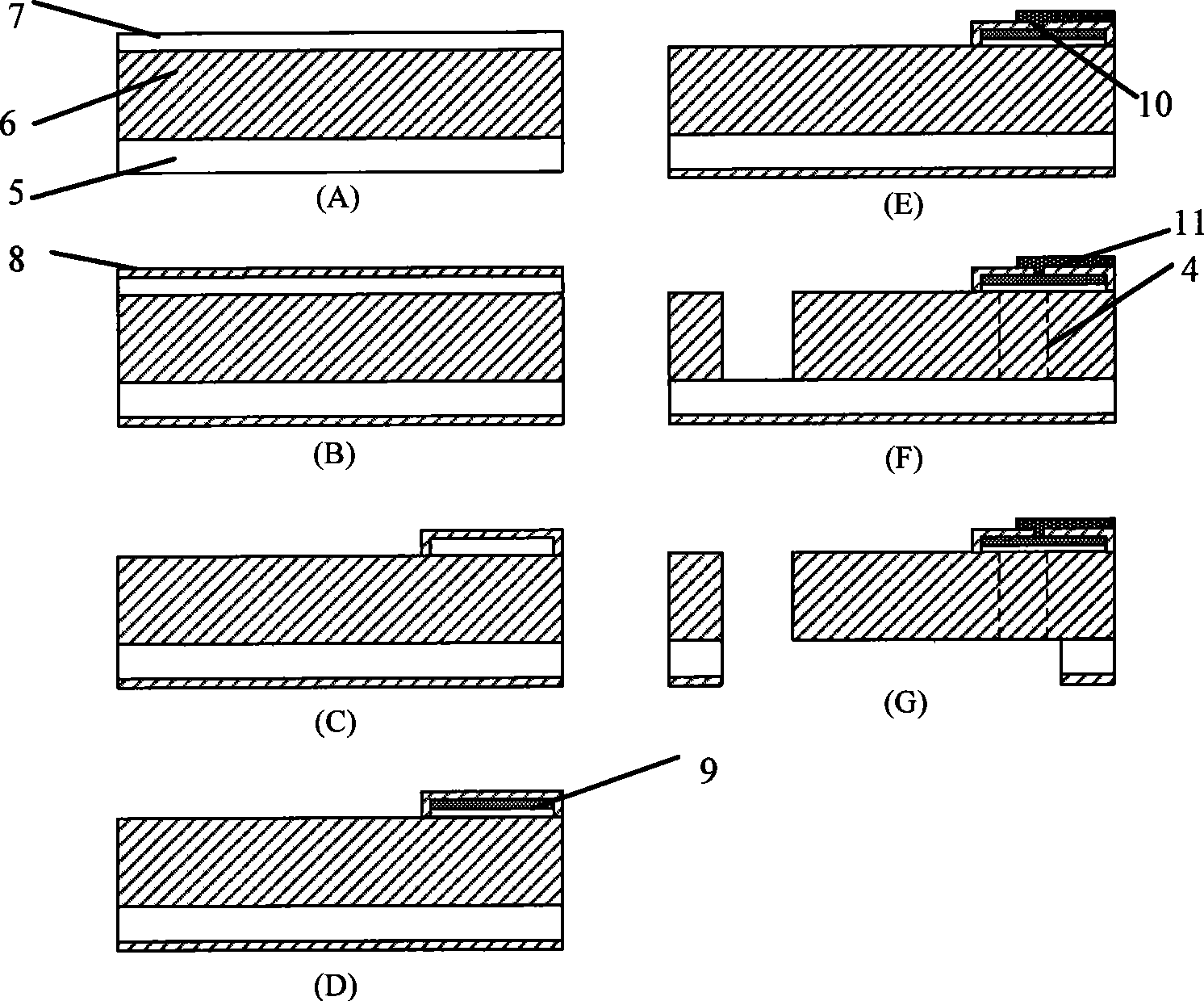

[0034] The invention belongs to micro-electromechanical system piezoresistive micro-cantilever sensor. The sensing unit includes a Wheatstone bridge composed of a detection cantilever beam 1, a reference cantilever beam 2 and four identical piezoresistive sensitive resistors R1, R2, R3, and R4. Such as figure 1, it is detected that three equidistant rectangular holes 4 are etched on the cantilever beam 1 as the stress concentration area, and there is no hole structure on the cantilever beam 2 for reference. As shown in Fig. 2(a), the two piezoresistive elements R1 and R3 integrated on the surface of the cantilever are respectively located on the two cantilever beams (R1 is arranged on the surface of the micro-cantilever beam in a U-shaped surrounding rectangular hole structure, and is close to the micro-cantil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com