Heat radiating device for LED and manufacturing method therefor

A technology of light-emitting diodes and heat sinks, which is applied to the cooling/heating devices of lighting devices, lighting devices, semiconductor devices of light-emitting elements, etc., and can solve the problem of insufficient flat surface area, unequal lifespan of light-emitting diodes, and poor contact between light-emitting diodes and heat pipe surfaces Close and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

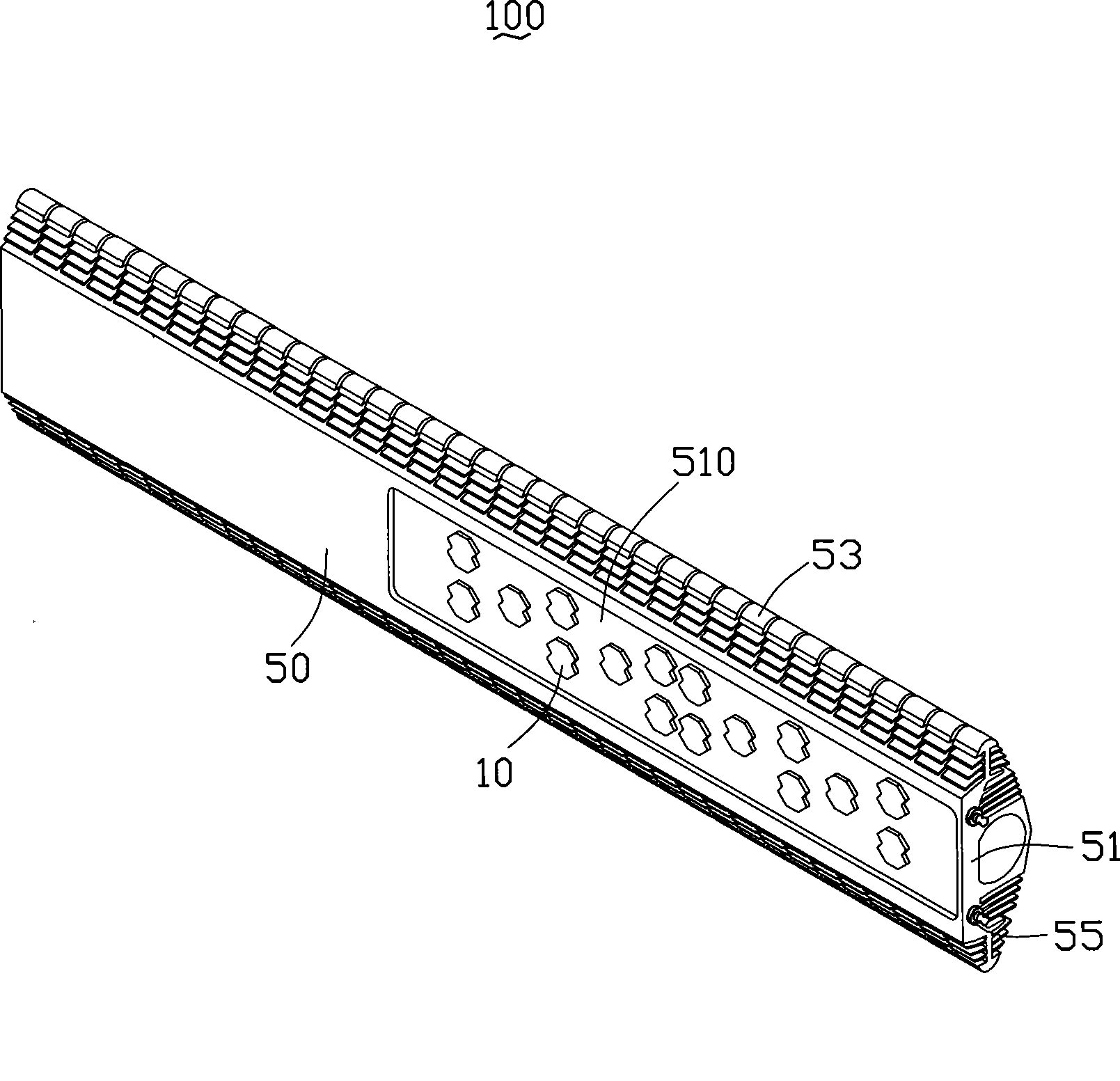

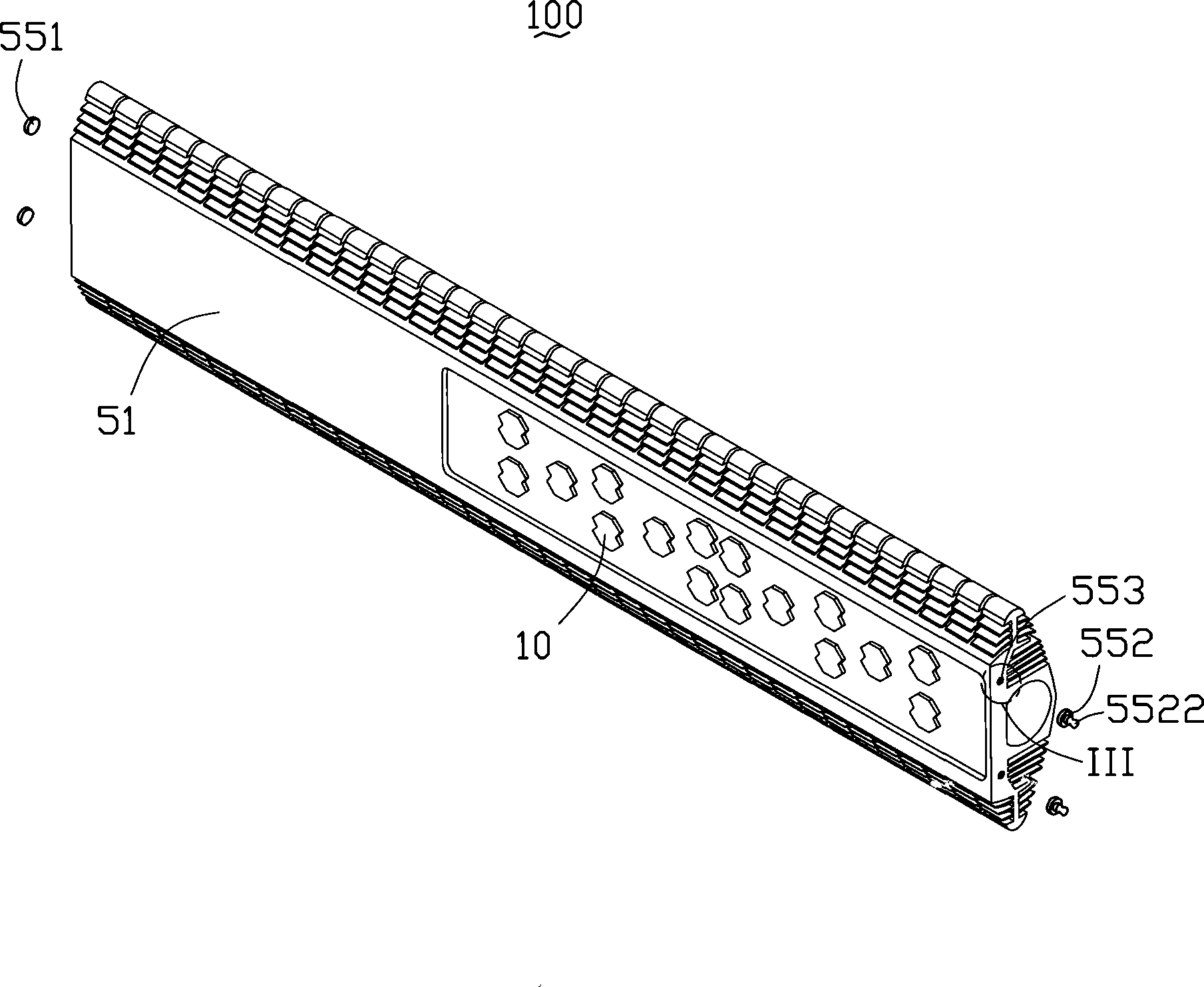

[0010] see figure 1 and figure 2 , is an LED lamp 100 according to an embodiment of the present invention. The lamp 100 includes a heat sink 50 and a plurality of LEDs 10 attached to the bottom of the heat sink 50 .

[0011] The heat dissipation device 50 includes a base plate 51 and a plurality of heat dissipation fins 53, and these heat dissipation fins 53 extend from the top surface and sides of the base plate 51 to expand the contact area between the heat dissipation device 50 and the surrounding air and improve heat dissipation. efficiency.

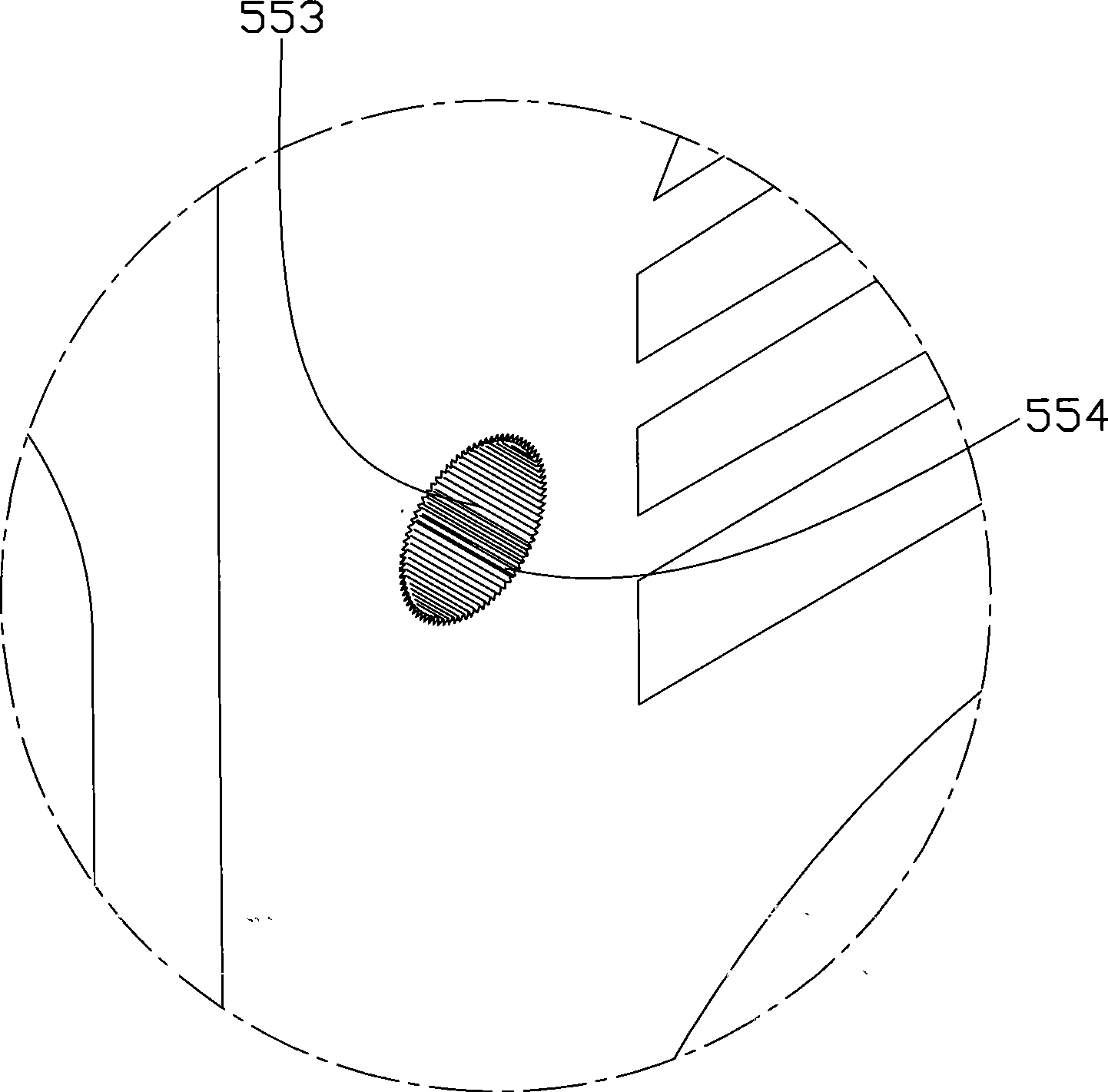

[0012] The substrate 51 is roughly in the shape of a rectangular plate with a certain thickness. A notch 510 is provided on the right side of the bottom of the substrate 51. The LEDs 10 are attached to the bottom surface of the notch 510. A The lampshade (not shown) snapped on the edge of the notch 510 . Please also see image 3 , the substrate 51 includes two channels 553 disposed at the bottom thereof and adjacent to the LEDs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com