Hydraulic motor with axial pistons

A hydraulic motor and axial piston technology, applied in the field of hydraulic motors, can solve the problems of changing the displacement of the motor, the displacement is not carried out gradually and comfortably, and it is unfavorable for the operator to intervene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

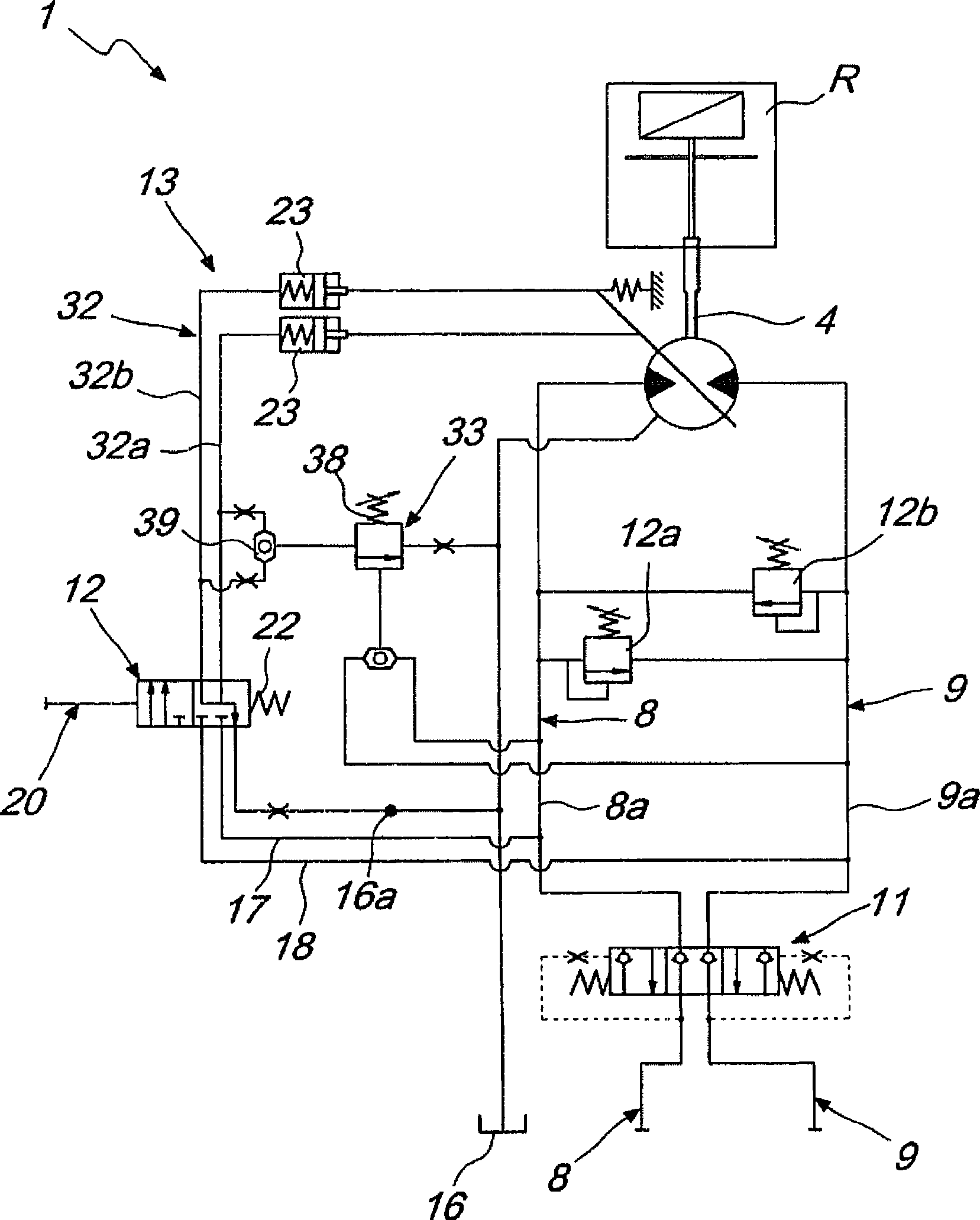

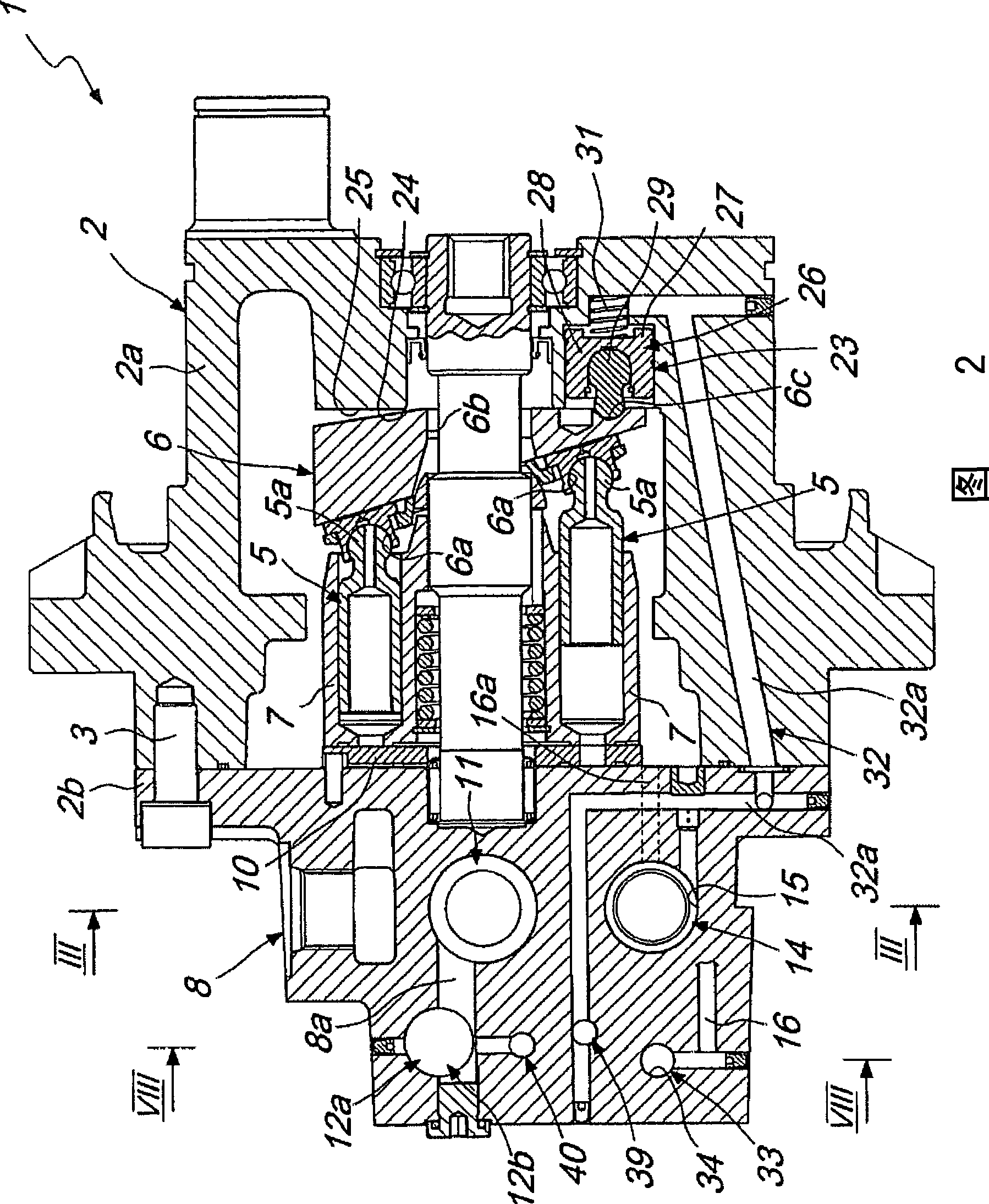

[0031] Referring to the drawings, reference numeral 1 generally denotes a hydraulic motor with an axial piston, in particular a hydraulic motor for driving a wheel drive of a crawler belt of a small excavator or the like.

[0032] Conventionally, the motor 1 can be placed on a small excavator (not shown in the figure), and together with the epicycloidal reducer unit R connected thereto, the motor 1 constitutes a so-called wheel drive for driving the crawler.

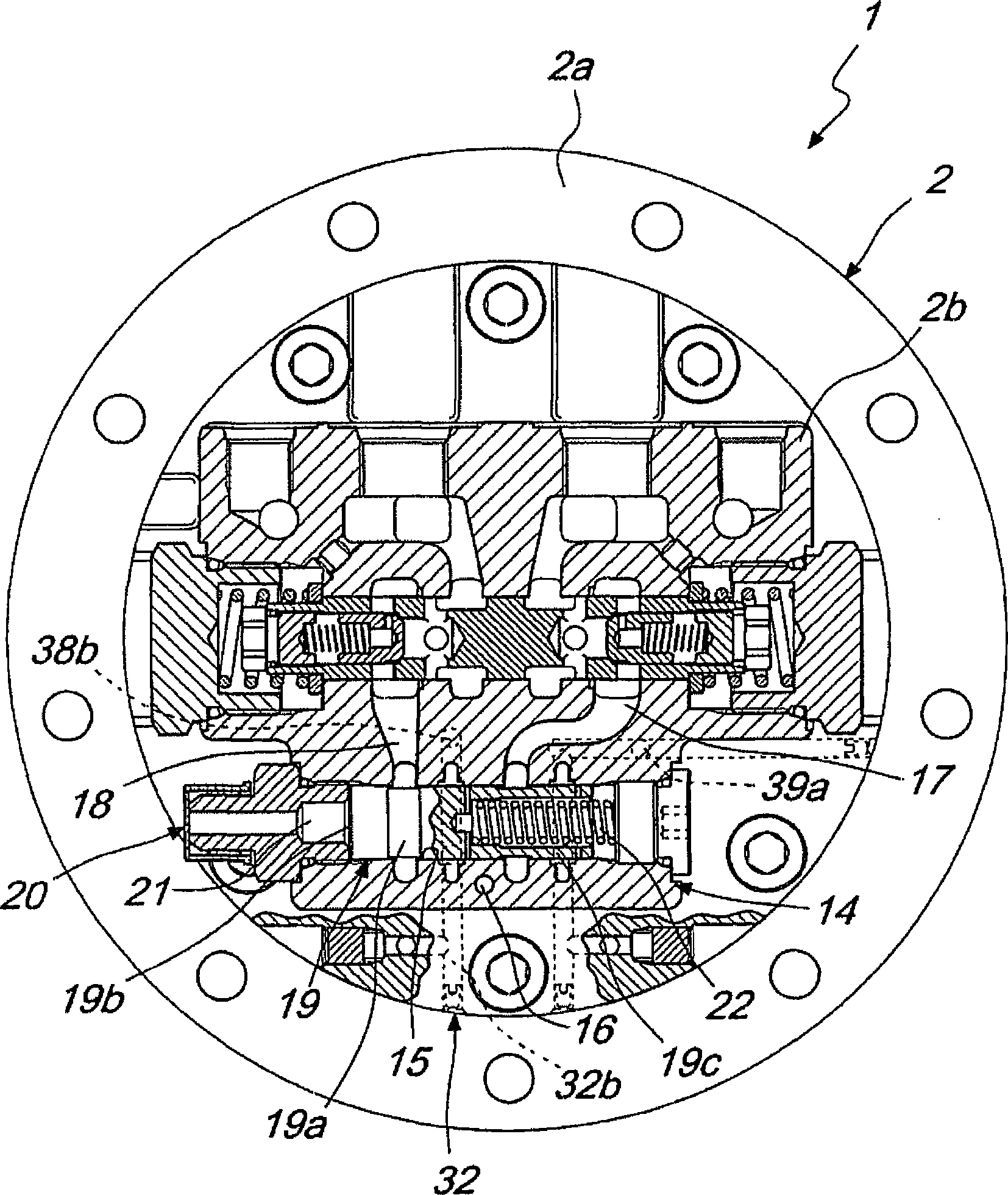

[0033] The motor 1 comprises a housing 2 divided into a first part 2a and a second part 2b, the second part 2b serving as a cover, said two parts being fixed to each other by means of conventional screw means 3 .

[0034] The first part 2a is hollow and houses inside it a motor shaft 4 and a plurality of pistons 5 parallel to the motor shaft and acting on an oscillating swash plate 6 having opposite faces inclined to each other. The second part 2b may be provided in two or more parts coupled to each other.

[0035] Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com