Perimeter injection moulding method and system device thereof

A system device and injection molding machine technology, applied in the direction of coating, etc., can solve the problems of high labor intensity and the influence of product production speed, and achieve the effect of reducing labor intensity, improving work efficiency and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

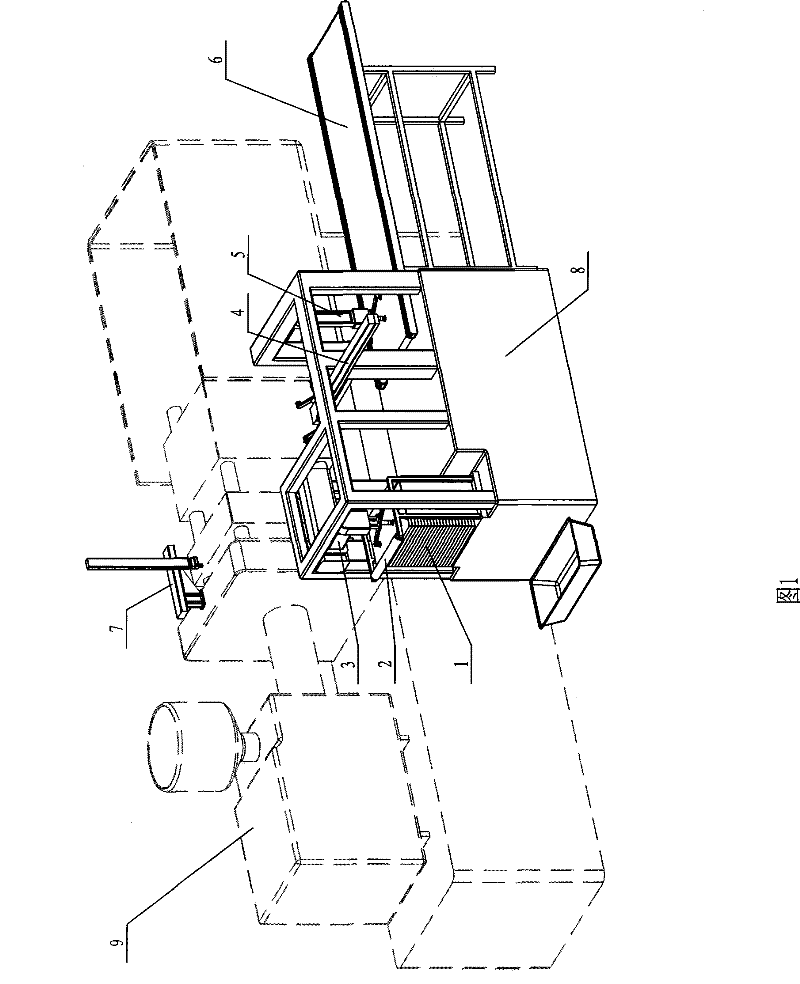

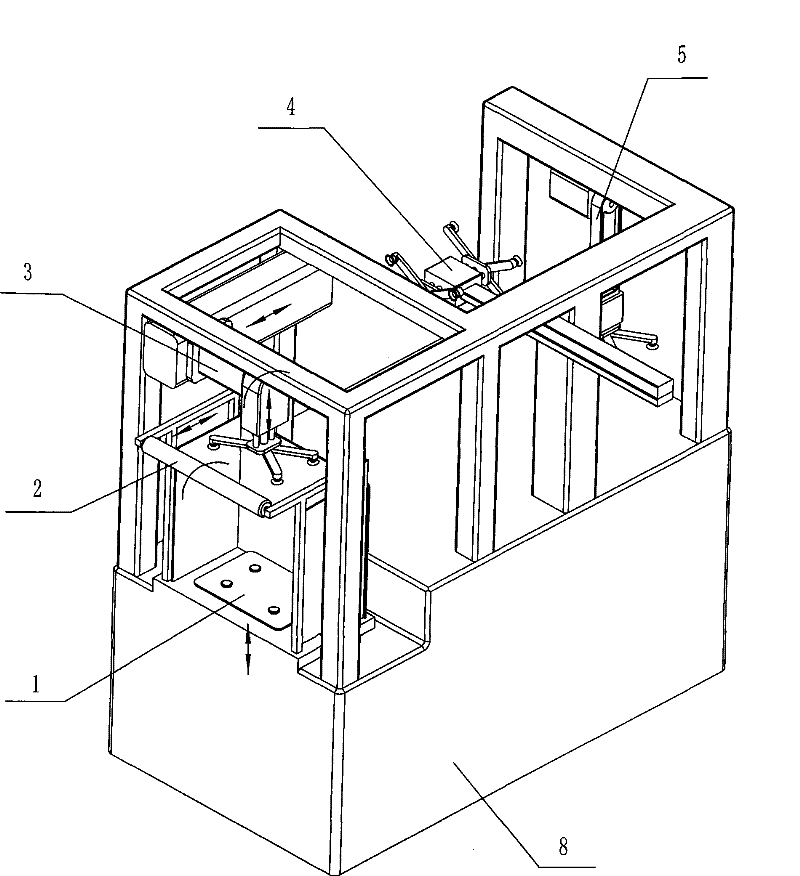

[0029] As shown in Figure 1, the peripheral injection molding system device is composed of a silo 1, a paper removal unit 2, a feeding unit 3, a feeding unit 4, a feeding unit 5, a conveyor belt 6, a nozzle unit 7 and a combined frame 8: among them

[0030] Combined frame 8: set on one side of the frame of the injection molding machine 9, it provides a basis for integrating the bin 1, the paper removal unit 2, the feeding unit 3, the feeding unit 4 and the feeding unit 5 into one.

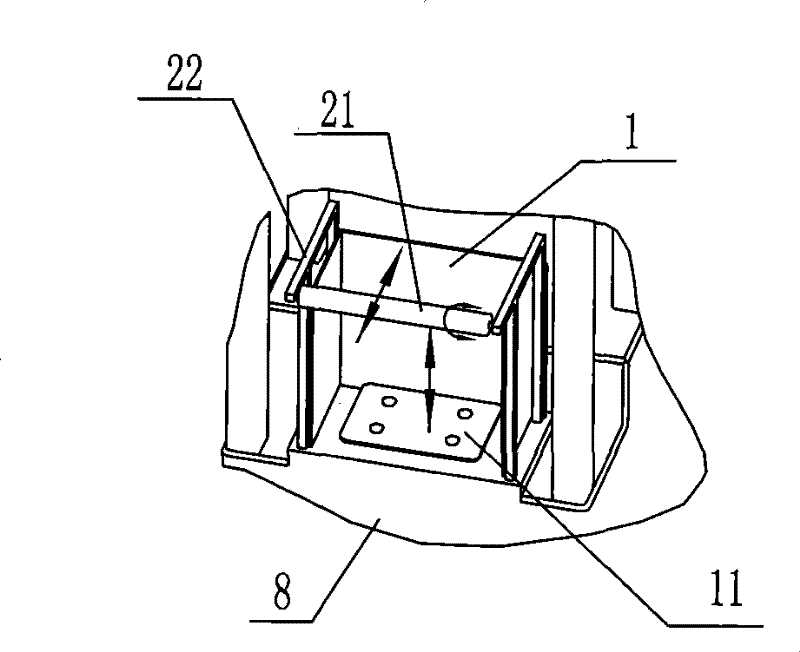

[0031] Silo 1: used to place semi-finished glass. There is a top plate 11 at the bottom of the silo. The top plate 11 is installed in the silo 1 by moving up and down. The adjustable length and width are suitable for glass products of different sizes; 120-150 pieces of glass can be stored inside, and based on the 30-second injection molding cycle, one feeding can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com