Purification method of teicoplanin

A technology for the purification of teicoplanin, which is applied in the field of purification of teicoplanin, can solve the problems of difficult crystallization and small change range, and achieve the improvement of effective components, change of appearance and color, and reduction of other impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Teicoplanin fermentation broth 100L, potency 1268μg / ml, containing 126.8g teicoplanin, adjusted pH to 9.5 with 1M NaOH, filtered into ceramic membrane, the pore size of ceramic membrane is 0.02μm. After filtration and top washing with water, 110 L of mixed filtrate was obtained, with a titer of 928 μg / ml, containing 102.08 g of teicoplanin. The macroporous adsorption resin on the filtrate is adsorbed, the volume of the resin is 4L, and the flow rate is 10L / hr. After washing the resin with water, after washing 6 times the column volume, elute with an aqueous solution containing 60% acetone and pH 3.5 at a flow rate of 8 L / hr to obtain 3.8 L of eluent with a titer of 14105 μg / hr. ml, pH6.9, containing 53.599g of teicoplanin. After adjusting the pH to 5.0 with 1M HCl, add 50 g of activated carbon to the eluate, stir for 30 minutes, and filter to obtain 3.7 L of decolorized solution with a titer of 12680 μg / ml, pH 4.8, and 46.916 g of teicoplanin. The decolorization solut...

Embodiment 2

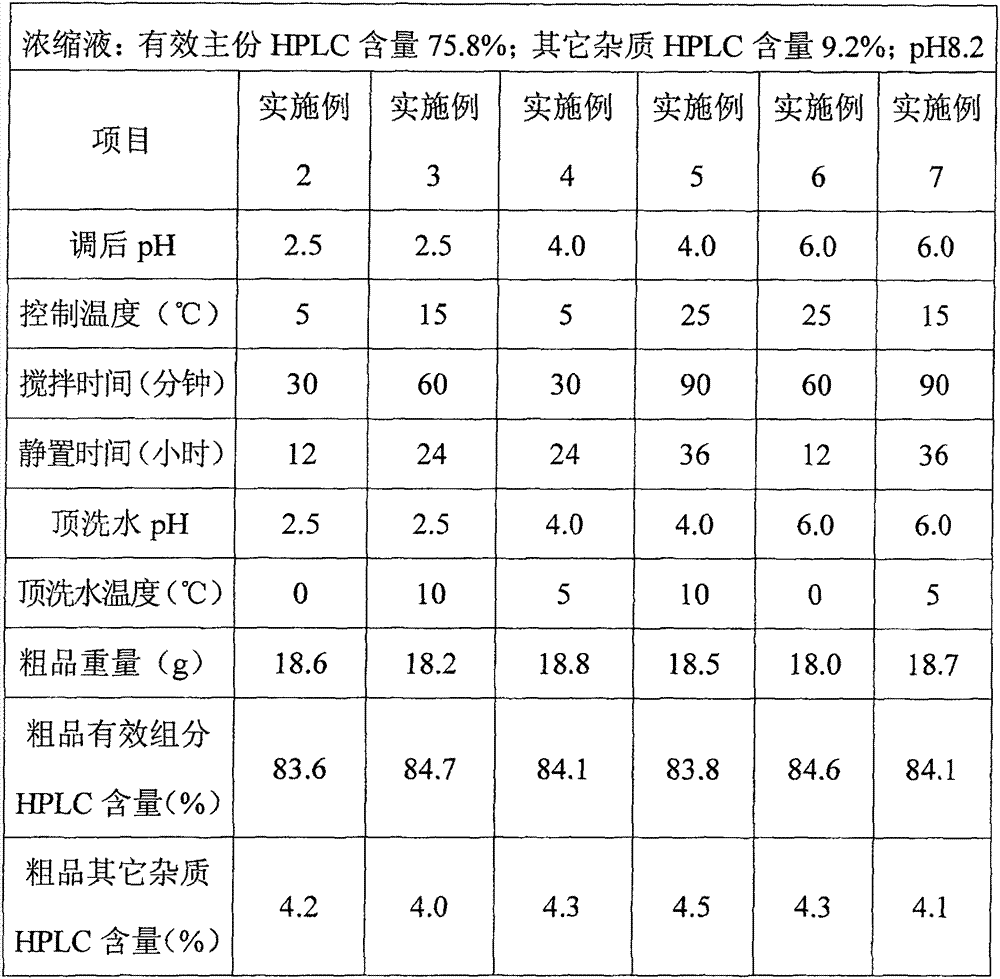

[0038] The concentration of the concentrated aqueous solution of teicoplanin obtained according to the method of Example 1 was 52000 μg / ml, the HPLC peak area ratio of the active ingredient was 75.8%, the HPLC peak area ratio of other impurities was 9.2%, the volume was 200ml, and the pH=8.2. After filtering through a 1 μm filter element, add 1M HCl solution while stirring to adjust the pH of the solution until the pH is stable at 2.5, from which teicoplanin is precipitated to form a suspension. After continuing to stir for 30 minutes, stop stirring, let stand for 12 hours, and control the process temperature at about 5°C. The mixture was filtered, and finally 50 ml of water was top-washed with pH=2.5 and temperature 0° C., and 18.6 g of wet crude product of teicoplanin was obtained after top-washing. The HPLC peak area ratio of the effective component of teicoplanin obtained by precipitation was 83.6%, and the HPLC peak area ratio of other impurities was 4.2%, and the appeara...

Embodiment 3

[0040] The concentration of the concentrated aqueous solution of teicoplanin obtained according to the method of Example 1 is 52000 μg / ml, and the effective component HPLC peak area ratio is 75.8% (, other impurity HPLC peak area ratios are 9.2%, volume 200ml, pH=8.2. By 1 μm Add 1M HCl solution while stirring to adjust the pH of the solution until the pH is stable at 2.5, and teicoplanin is separated out from it to form a suspension. Continue to stir for 60 minutes and then stop stirring, let stand for 24 hours, process temperature control At about 15°C. The mixture is filtered, and finally 50ml of water with pH=2.5 and temperature of 10°C is used for top washing, and 18.2g of wet crude product of teicoplanin is obtained after top washing. Part HPLC peak area ratio is 84.7%, other impurity HPLC peak area ratio is 4.0%, product outward appearance color obtains obvious improvement simultaneously.See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com