Method of preparing vancomycin through cyclopentadiene-acrolein

A technology of vancomycin and cyclopentadiene, applied in the direction of peptides, etc., can solve the problems of slow growth of vancomycin hydrochloride crystals, difficult crystallization, and difficult crystallization, and achieve simple production methods, improved effective components, Effect of appearance color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

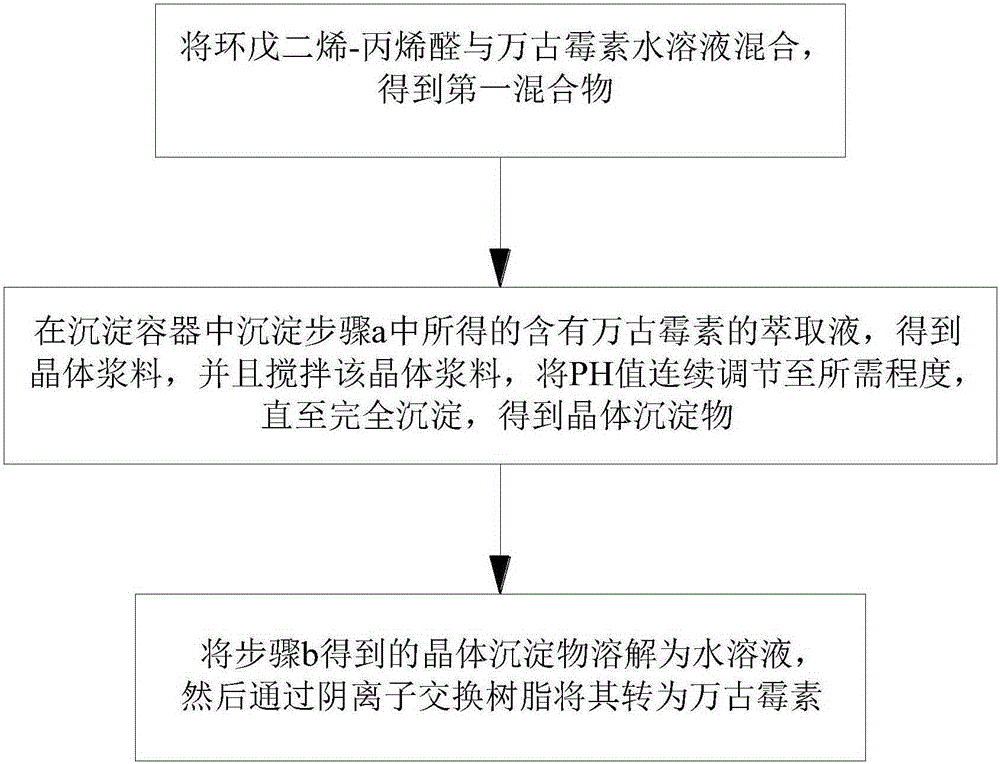

[0019] see figure 1 , the invention provides a kind of preparation method that prepares vancomycin by cyclopentadiene-acrolein, comprises the following steps:

[0020] a. Mixing cyclopentadiene-acrolein and vancomycin aqueous solution to obtain a first mixture, and making the pH of the first mixture less than 6, dividing the first mixture into an oil phase and an aqueous phase, Separate the oil phase to obtain an extract containing vancomycin;

[0021] b. Precipitate the vancomycin-containing extract obtained in step a in a precipitation container to obtain a crystal slurry, and stir the crystal slurry to continuously adjust the pH value to the required level until complete precipitation to obtain a crystal precipitate ;

[0022] c. Dissolving the crystal precipitate obtained in step b into an aqueous solution, and then converting it to vancomycin through an anion exchange resin.

[0023] According to step a, the pH range of the cyclopentadiene-acrolein is 1.0-3.0.

[0024...

Embodiment 1

[0029] Include the following steps:

[0030] a. Mix cyclopentadiene-acrolein and vancomycin aqueous solution to obtain the first mixture, and make the pH value of the first mixture 6, divide the first mixture into an oil phase and an aqueous phase, separate The oil phase is removed to obtain an extract containing vancomycin, and the pH of the cyclopentadiene-acrolein is 3.0;

[0031] b. Precipitate the vancomycin-containing extract obtained in step a in a precipitation container to obtain a crystal slurry, and stir the crystal slurry to continuously adjust the pH value to the required level until complete precipitation to obtain a crystal precipitate , the initial temperature of the crystallization process is 60°C; the end temperature of the crystallization process is 30°C; the cooling rate of the crystallization process is 5°C / min;

[0032] c. Dissolving the crystal precipitate obtained in step b into an aqueous solution, and then converting it to vancomycin through an anion...

Embodiment 2

[0034] Include the following steps:

[0035] a. Mix cyclopentadiene-acrolein and vancomycin aqueous solution to obtain the first mixture, and make the pH value of the first mixture 3, divide the first mixture into an oil phase and an aqueous phase, separate The oil phase is removed to obtain an extract containing vancomycin, and the pH range of the cyclopentadiene-acrolein is 1.0;

[0036] b. Precipitate the vancomycin-containing extract obtained in step a in a precipitation container to obtain a crystal slurry, and stir the crystal slurry to continuously adjust the pH value to the required level until complete precipitation to obtain a crystal precipitate , the initial temperature of the crystallization process is 25°C; the end temperature of the crystallization process is 0°C; the cooling rate of the crystallization process is 0.5°C / min;

[0037] c. Dissolving the crystal precipitate obtained in step b into an aqueous solution, and then converting it to vancomycin through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com