Light guide board

A light guide plate and light source technology, applied in the field of light guide plates, can solve the problems of poor pass rate of light guide plates, time-consuming and costly processing, etc., and achieve the effect of improving the pass rate of processing and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

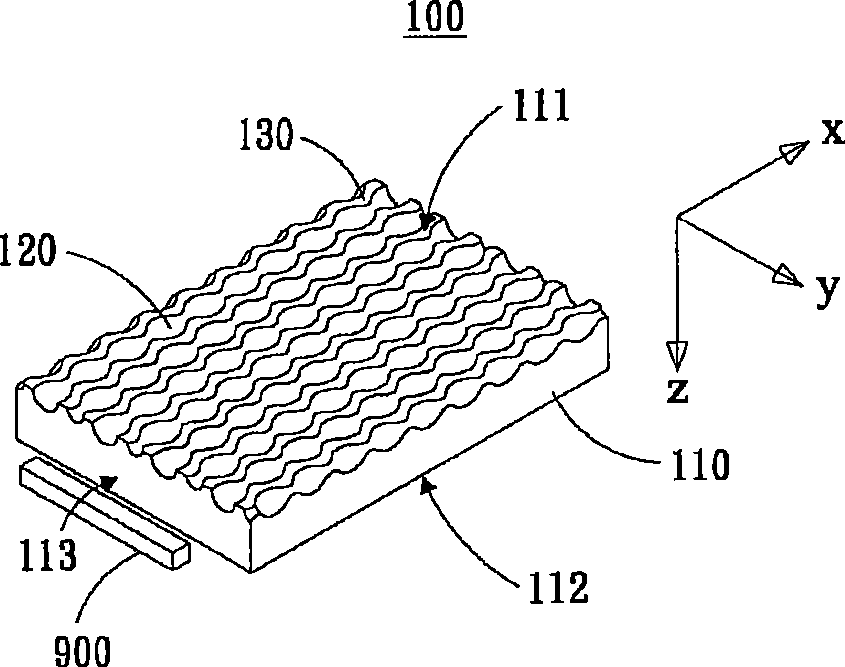

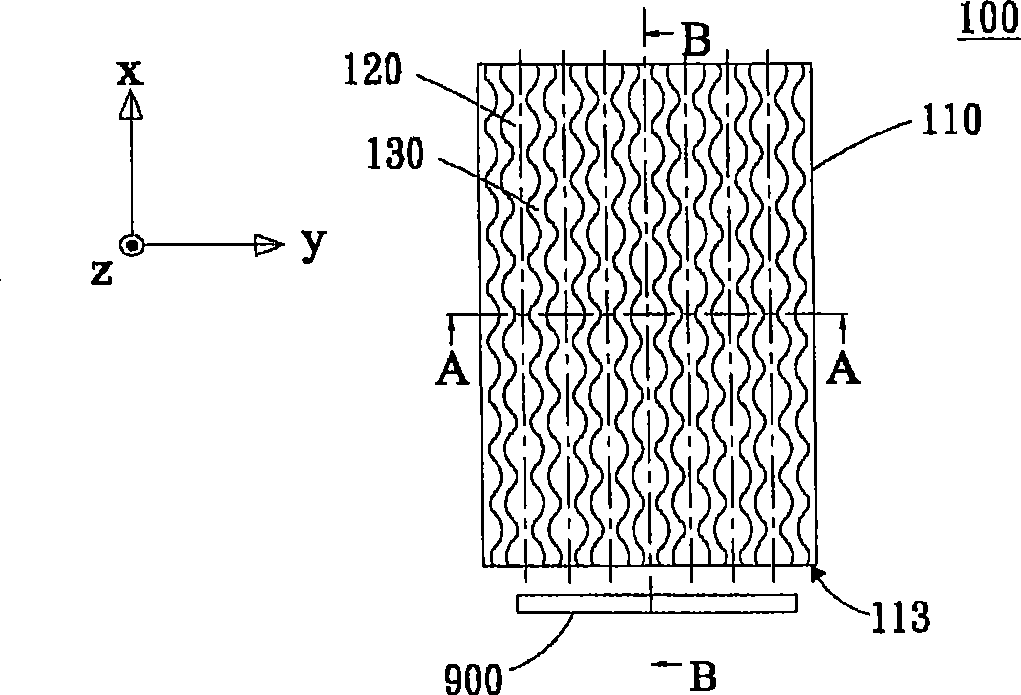

[0032] see figure 1 and figure 2 As shown, a light guide plate 100 disclosed in the first embodiment of the present invention is used to guide the light of a light source, change the direction of the light, and make the light uniformly pass through a liquid crystal panel. The light guide plate 100 includes a transparent layer 110 and a plurality of micro grooves 120 formed on the transparent layer 110 .

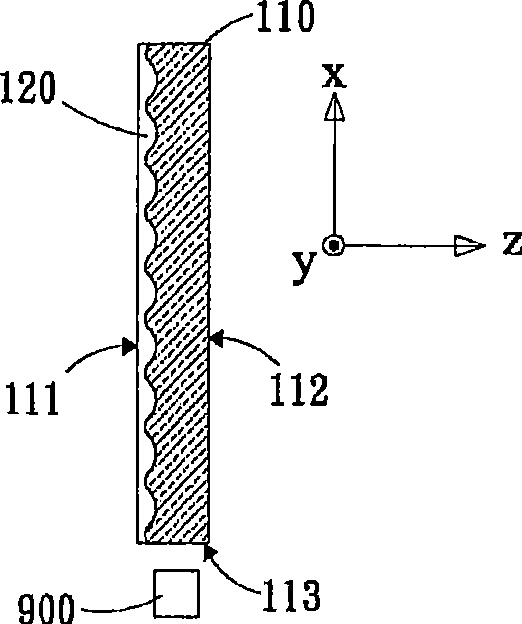

[0033] see again figure 1 , figure 2 , image 3 and Figure 4 As shown, the light-transmitting layer 110 has a light incident surface 113, a first plane 111 and a second plane 112, the first plane 111 and the second plane 112 are respectively connected to two opposite sides of the light incident surface 113, and The first plane 111 is opposite to the second plane 112 . Wherein, the light source 900 is disposed on one side of the light-incident surface 113 , so that light enters the light-transmitting layer 110 through the light-incident surface. The light is uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com