Automatic wire-distributing and wire-connecting system apparatus for packaging autolisp

A system device, assembly line technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of inability to adapt to wiring accuracy and fast response, high-line packaging products, wiring errors, long time, etc. problems, to achieve the effect of performance display, improve efficiency, and reduce the connection error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

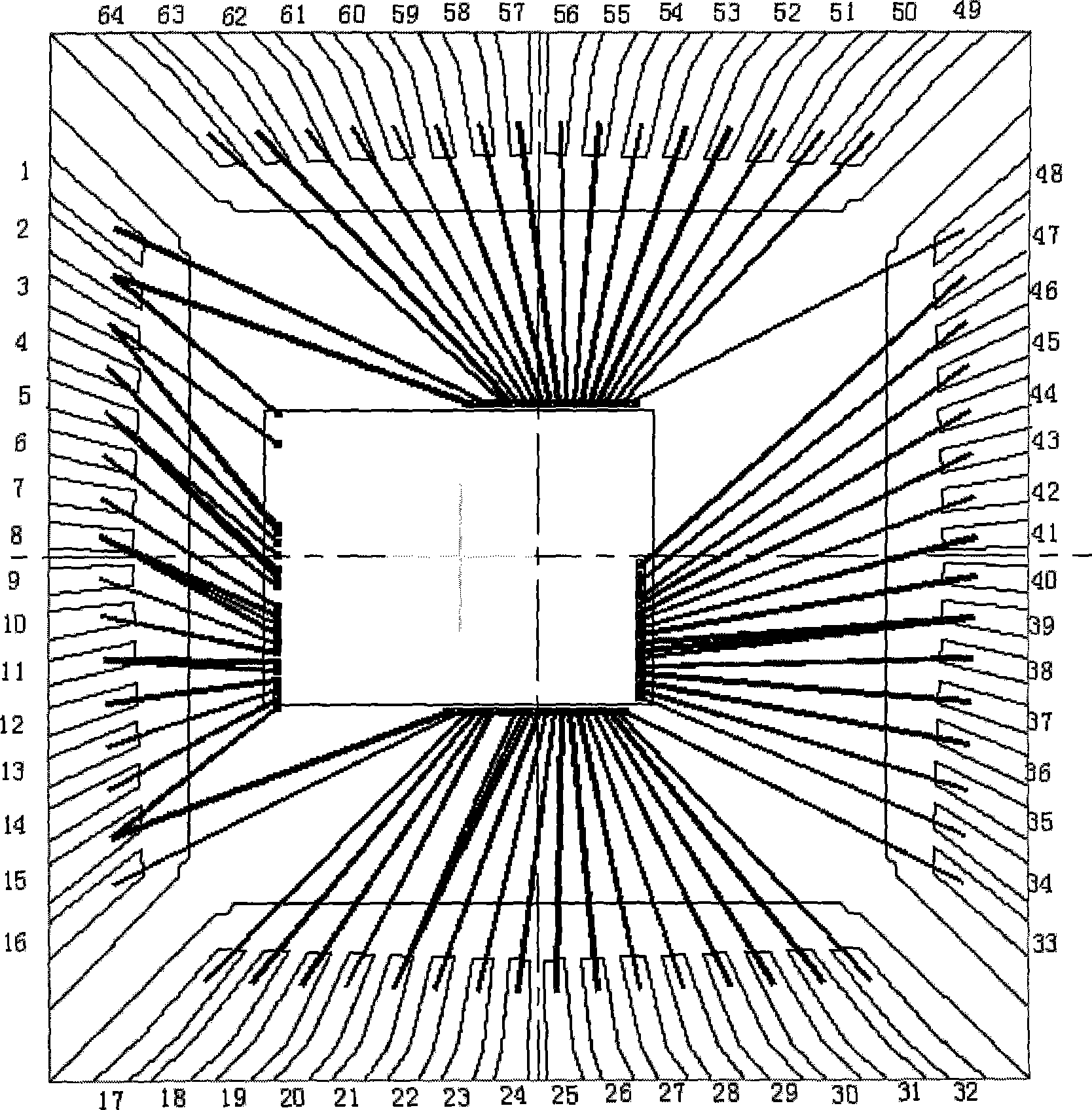

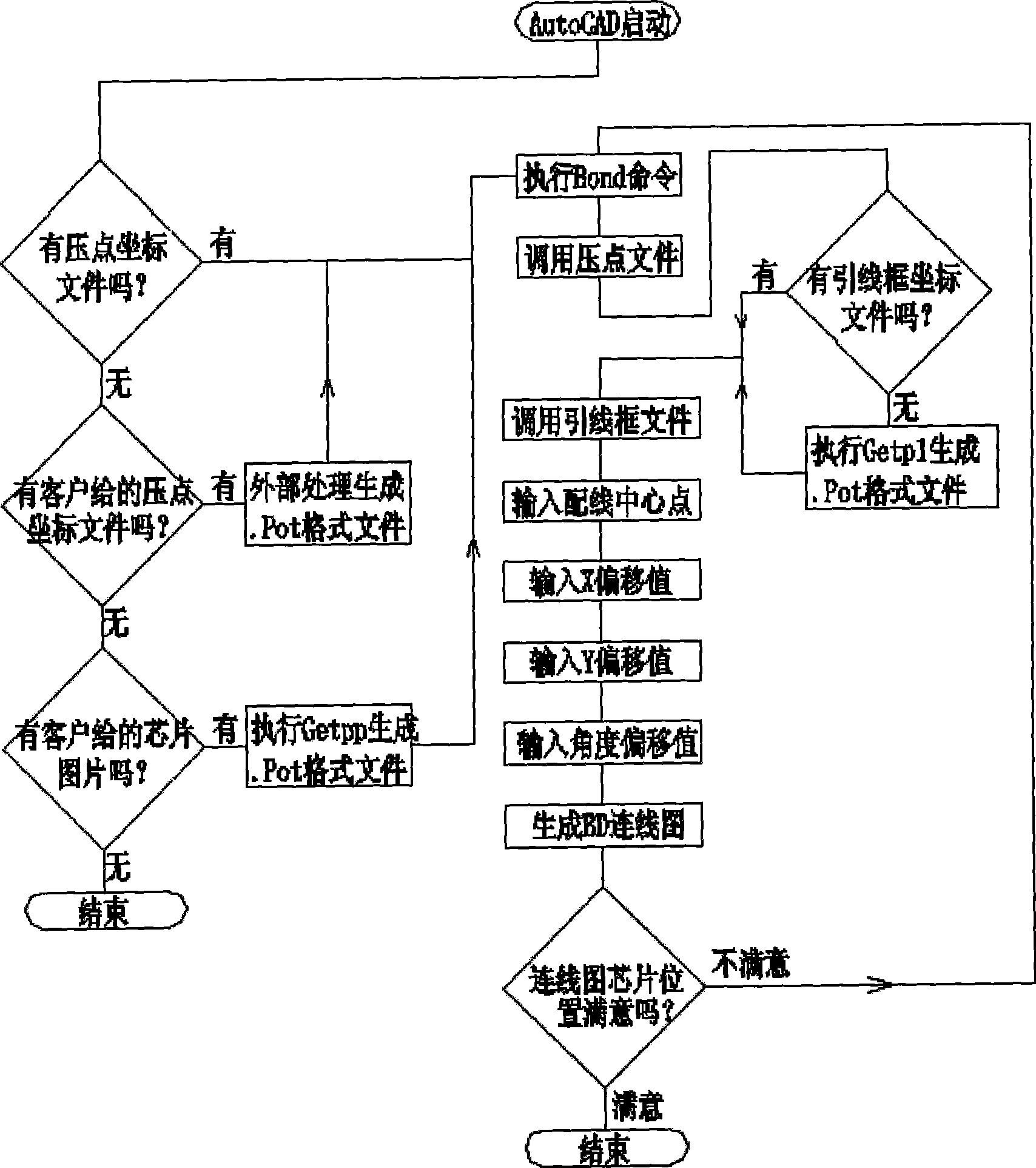

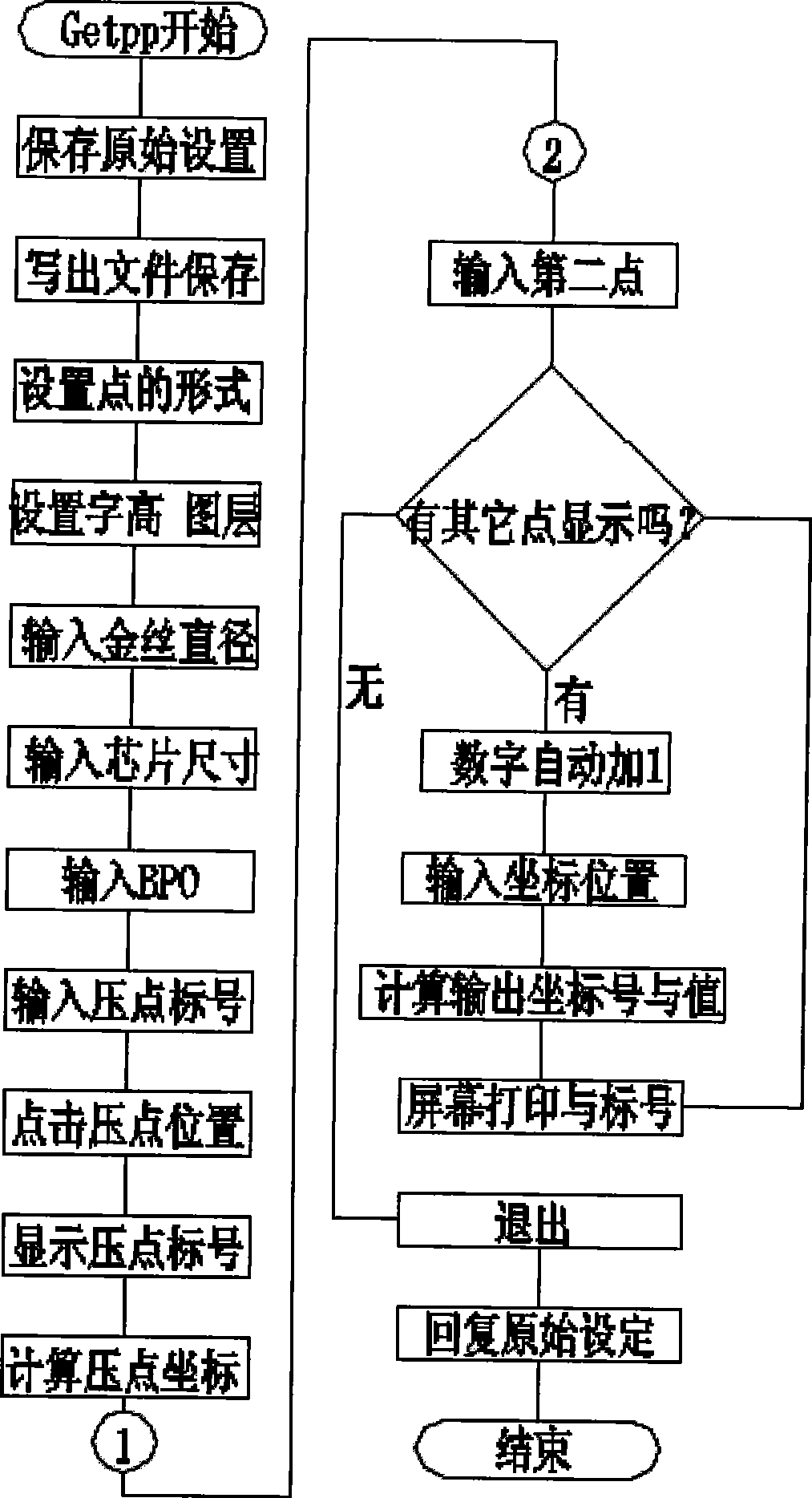

[0014] The present invention runs under the environment after the AutoCAD R14 version of Windows95 / 98 / ME / XP / 2003 or above operating system or higher version runs, is compiled and completed by AutoLisp language, and it comprises lead frame coordinate data extraction device Getpl (wherein Getpl It is the English abbreviation of the self-defined Get point one, which means to obtain the coordinates of a point on each foot of the lead frame), and the pressure point extraction device Getpp on the chip image (where Getpp is the English abbreviation of the self-defined Get picture point, which means to obtain the picture Coordinates of pressing points), automatic wiring device Bond (wherein Bond is the English abbreviation of self-defined Auto Wire Bond, which means automatic wiring connection), automatic erasing device Delbd (wherein Delbd is a custom Auto Wire Bond DeleteBond Drawing English abbreviation, which means to automatically erase the wiring diagram) four parts, which will e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com