Integrated apparatus used for fuel cell humidifying

A fuel cell and integrated technology, applied in the direction of fuel cells, fuel cell additives, solid electrolyte fuel cells, etc., can solve the problems of low humidification efficiency, large pressure loss, large humidification stack volume, etc., and achieve humidification efficiency High, increased humidification capacity, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

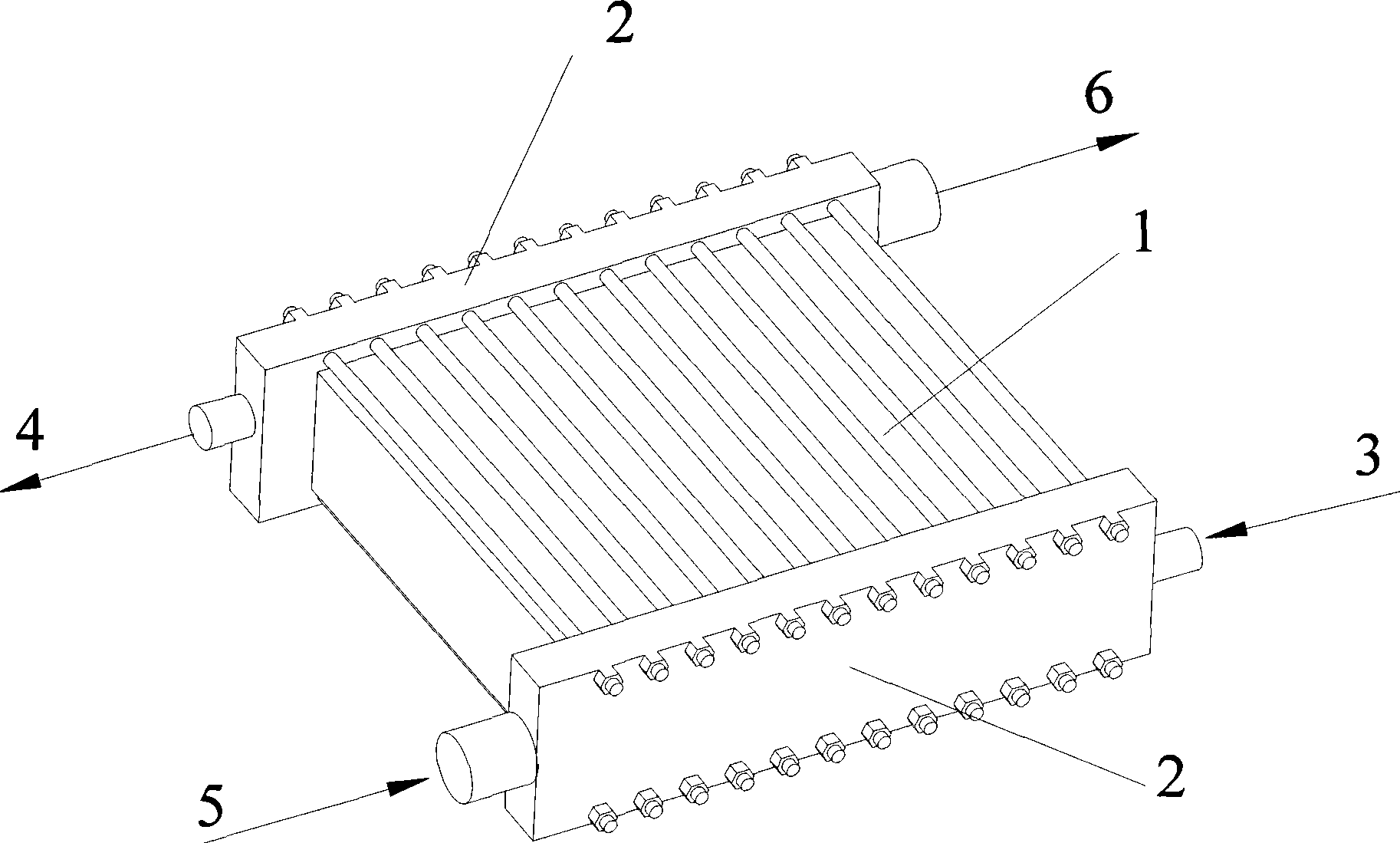

[0036] like figure 2 As shown, an integrated external humidification device for fuel cell cars has a length of 500mm, a width of 150mm, and a height of 200mm. Collector plate 7, terminal end plate 2a, 2b, described humidification pile 1 comprises 20 deflectors, 40 diaphragms, the deflectors and diaphragms are 40mm long and 10mm wide, and the diaphragms are water-permeable Air film, a diaphragm is interposed between the deflector and the deflector to form a humidification unit, and the humidification unit is stacked up and down to form a humidification part, and the air humidification stack 1a is formed by the air deflector , Diaphragm and cooling water deflector are stacked in sequence. Air deflectors are provided with air deflectors on both sides of the air deflector, and cooling water deflectors are provided on both sides of the cooling water deflector. Air inlet and outlet holes and cooling water inlet and outlet holes are arranged on the flow plate and the cooling water ...

Embodiment 2

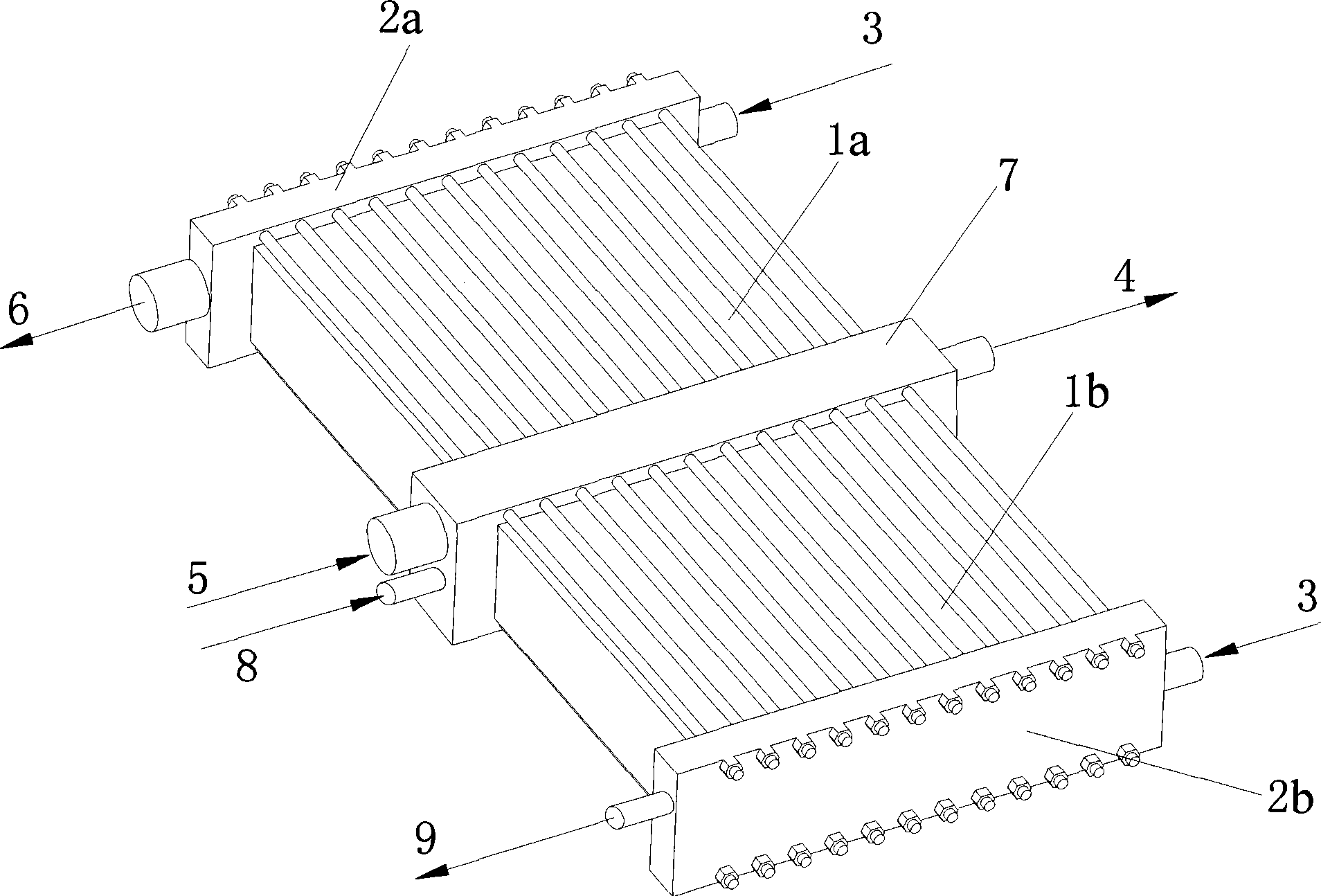

[0039] like image 3 As shown, an integrated external humidification device for a fuel cell forklift is 300mm long, 250mm wide, and 250mm high. , the humidification stacks 1a and 1b are respectively arranged at the upper and lower positions on the same side of the central collector plate 7, the humidification stack 1a includes a hydrogen humidification part 11a and an air humidification part 12a, and the hydrogen humidification part 11a is close to the central collector plate 7. The air humidifying part 12a is close to the terminal end plate 2a; the humidifying stack 1b includes a hydrogen humidifying part 11b and an air humidifying part 12b, the hydrogen humidifying part 11b is close to the central collector plate 7, and the air humidifying part 12b is close to the terminal end plate 2b, after the air flows in from the air inlet pipe 5 on the central collector plate 7, it flows into the two humidifying stacks 1a, 1b at the upper and lower positions respectively, passes throug...

Embodiment 3

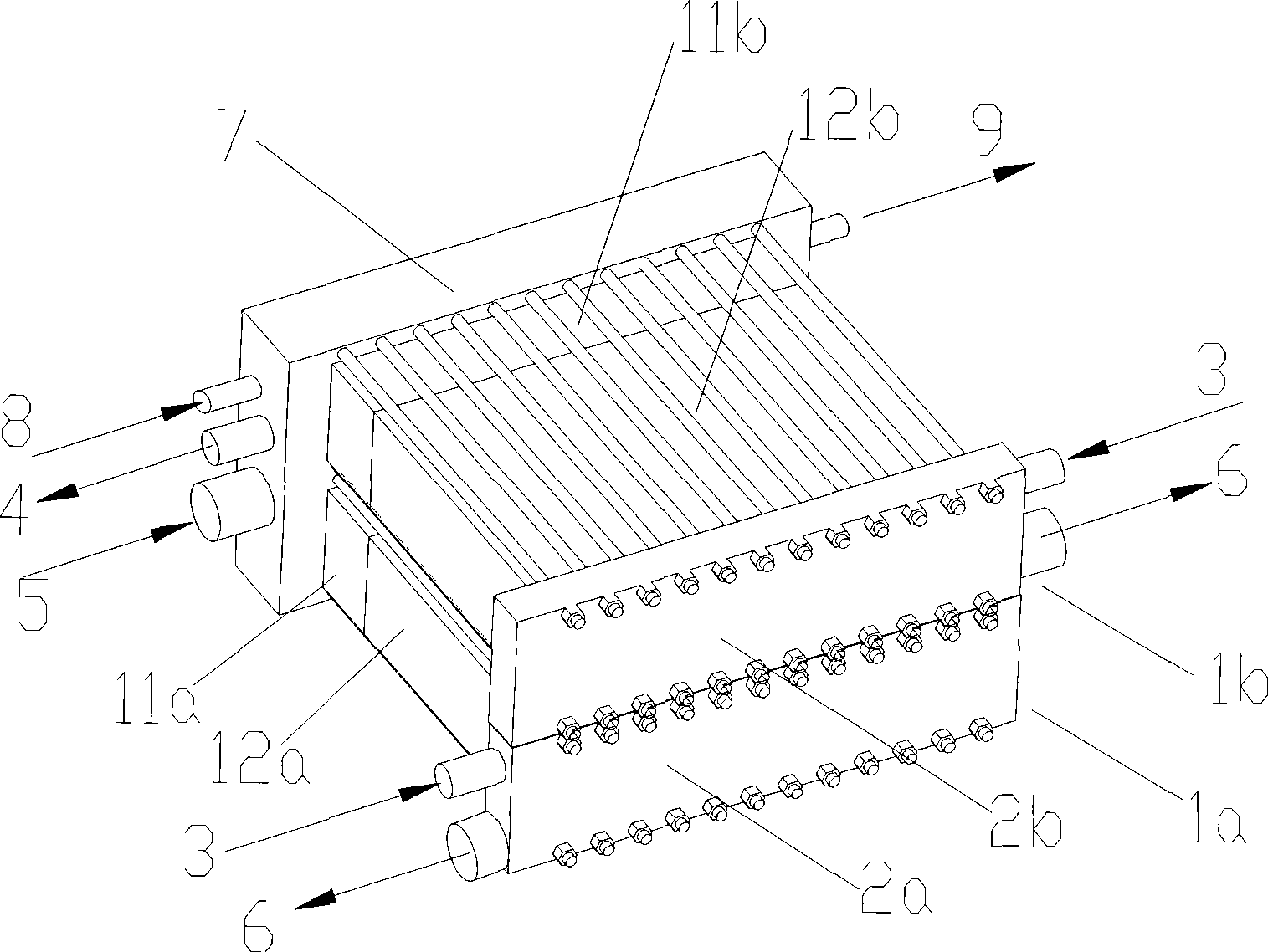

[0042] like Figure 4 As shown, an integrated external humidification device for a fuel cell bus, the device includes four sets of humidification stacks 1a, 1b, 1c, 1d, a central collector plate 7, end end plates 2a, 2b, 2c, 2d, The four groups of humidifying stacks 1a, 1b, 1c, and 1d are respectively arranged at the front, rear, left, and right ends of the central collector plate 7, wherein the humidifying stacks 1a are all composed of hydrogen humidification parts, and the humidifying stacks 1b, 1c are all composed of air humidification The humidification stack 1d is composed of a hydrogen humidification part 11d and an air humidification part 12d, the hydrogen humidification part 11d is close to the end end plate 2d, and the air humidification part 12d is close to the central collector plate 7.

[0043] Air flows in from the air inlet pipes 5 on the terminal end plates 2b, 2c, 2d of the humidification stacks 1b, 1c, 1d, and flows out from the air outlet pipes 6 on the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com