Ultrasonic straight line motor and automatic focusing/zooming system driven thereby

A linear motor and auto-focusing technology, applied in generator/motor, camera focusing device, projector focusing device, etc., can solve problems such as quick start and stop response, imaging error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

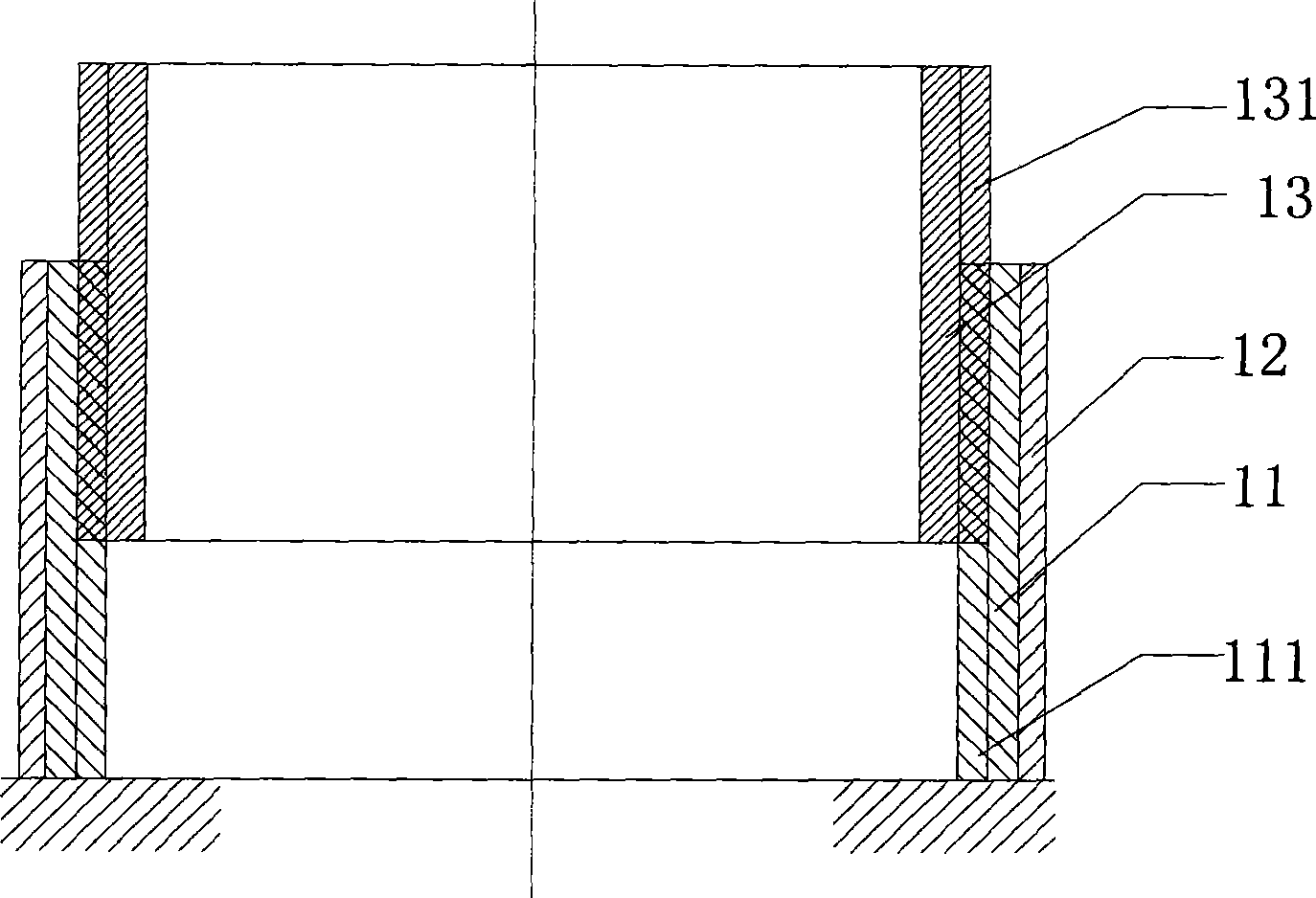

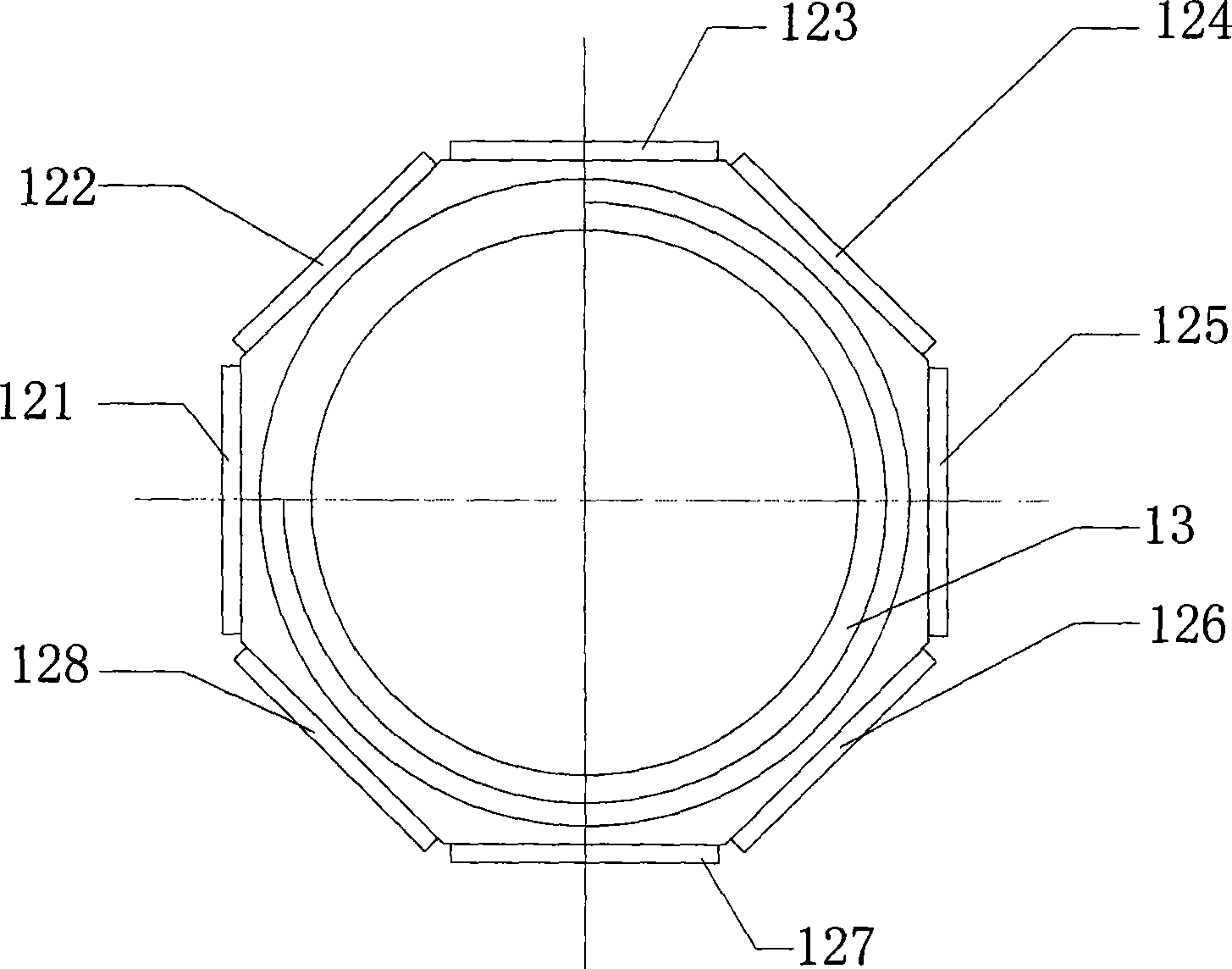

[0045] It is an octahedral ultrasonic linear motor driven by two-stage threads, and its basic structure is as follows: Figure 3a and Figure 3b As shown, it consists of an outer cylinder stator, a middle cylinder rotor, an inner cylinder and a guide mechanism.

[0046] The base 31 of the outer cylinder stator is a hollow barrel-shaped regular octahedron of metal material, and its inner wall is processed with threads 311; the outer surface of the stator base 31 is fixed with a piezoelectric sheet 32, and in this embodiment, the piezoelectric sheet 32 includes eight The piezoelectric sheets 321-328, the piezoelectric sheets 321-328 will generate the required mechanical vibration traveling waves after being excited.

[0047] Usually, the piezoelectric plates on the polyhedral stator are sequentially fed with two-phase orthogonal voltages, that is, the voltages whose phases are sinωt and cosωt respectively. Each piezoelectric sheet vibrates correspondingly after being excited...

Embodiment 2

[0054] Example 2 is a variant of Example 1. The difference between it and the above-mentioned Embodiment 1 is that the guide rod 35 integrates a column 351 for shape retention, such as Figure 4a and Figure 4b As shown, the column 351 fixed on the stator and the guide rod 35 are integrally formed. The cross section of the column 351 is a right triangle, and the cross section of the guide rod 351 is an arc shape. The middle of the hypotenuse of the triangle protrudes. The guide rod 35 with a circular arc cross section is embedded in the chute 341, and the two right-angled surfaces of the column 351 are respectively on the same plane as the adjacent piezoelectric sheet, so that the two columns located at the outer corners of the octahedral motor 351 (also can be four) expands the external shape of whole motor to more regular tetrahedron, and this column 351 also can play the effect of keeping shape to the corner part of octagonal motor, is more conducive to picking up and ins...

Embodiment 3

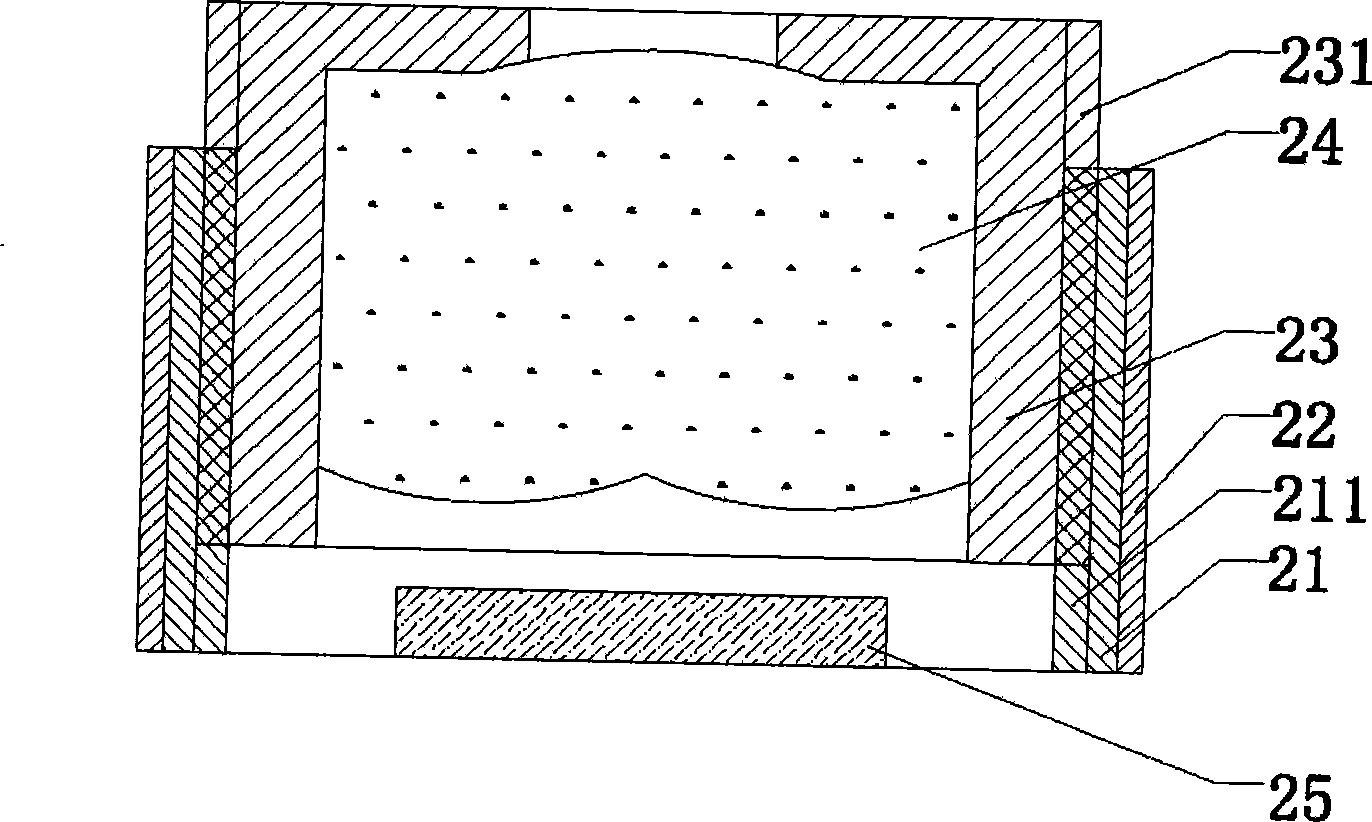

[0056] Embodiment 3 On the basis of Embodiment 1, an optical lens and a photosensitive chip are added to form an AF Lens Module. Such as Figure 5a and Figure 5b As shown, a group of optical lenses 443 are embedded in the inner tube 44 for collecting external visual signals. At the same time, on the plane perpendicular to the optical axis of the optical lens 443 at the center of the bottom of the motor, a photosensitive chip 471 is fixed to convert the optical signal collected from the lens group into an electrical signal to provide material for further image processing.

[0057]A square cavity is provided at the bottom of the stator base 46 for accommodating a photosensitive chip 471 . In the embodiment, the photosensitive chip 471 is firstly fixed on a flexible circuit board (FPC) 47 , and the flexible circuit board 47 is then fixed on the bottom frame of the stator base 46 . The other end of the flexible circuit board 47 has a circuit interface 472 external to the photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com