Process and equipment for synthesis of sub-micron 4A zeolite with continuous crystallization

A submicron, crystallization technology, applied in the direction of crystalline aluminosilicate zeolite, A-type crystalline aluminosilicate zeolite, etc., can solve the problems that large particles are easy to deposit into clothes or sewer pipes, and the application effect is poor, so as to achieve convenient Industrialized production, high crystallinity, repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

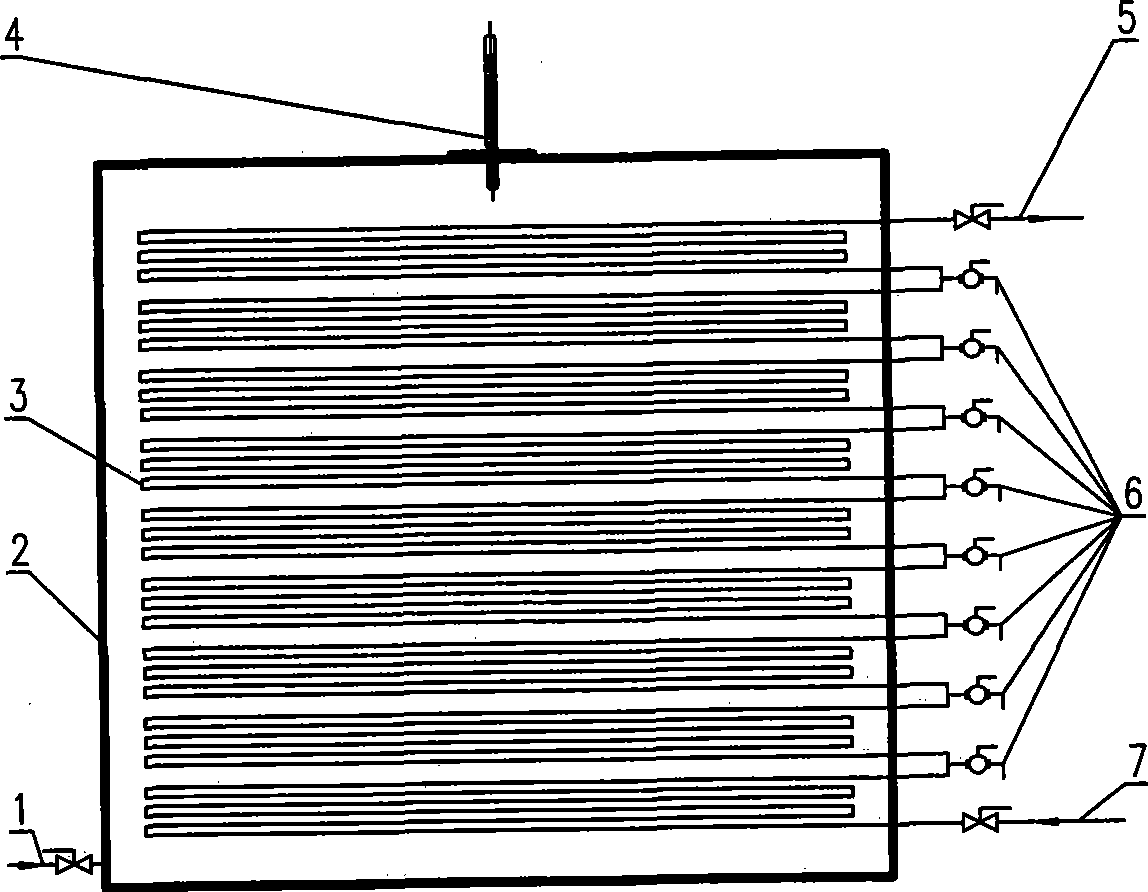

[0024] Dissolve sodium silicate with a modulus of 2.0 in water or alkaline water to form a sodium silicate solution (Na 2 O: 45g / L; SiO 2 : 120g / L), sodium aluminate is dissolved in NaOH solution to configure sodium aluminate solution (Na 2 O: 90g / L; AL 2 o 3 : 60g / L). The above two solutions are based on a silicon-aluminum molar ratio of 2:1, the flow rate of the sodium aluminate solution is 0.5L / h, and the flow rate of the sodium silicate solution is 0.28L / h, and they are respectively continuously fed into the online high-shear emulsifier through the pipeline Carry out mixed reaction gelation, after passing through the aging tank, enter the crystallization tube 3 from the feed port 7 of the temperature-controllable tubular flow crystallization reactor through a pump, and control the heating through the thermometer at the temperature measuring port 4 on the upper part of the constant temperature tank 2 The regulating valve of the steam port 1 reaches the temperature of th...

Embodiment 2

[0026] Dissolve sodium silicate with a modulus of 3.2 in water or alkaline water to form a sodium silicate solution (Na 2 O: 75g / L; SiO 2 : 180g / L), sodium aluminate is dissolved in NaOH solution to configure sodium aluminate solution (Na 2 O: 70g / L; AL 2 o 3 : 40g / L). The above-mentioned two kinds of solutions are carried out according to the silicon-aluminum molar ratio of 5:1, the flow rate of the sodium aluminate solution is 1L / h, and the flow rate of the sodium silicate solution is 0.65L / h. The mixed reaction is gelled, and after passing through the aging tank, it is pumped into a temperature-controllable tubular flow crystallization reactor for crystallization (heating to 65°C, flow rate 1m / min, residence time 30min). After crystallization, the mother liquor is removed by a continuous filter washing device and the pH value is washed with deionized water to 10 (the filtered mother liquor is reused in the preparation of sodium aluminate solution). Finally, it is dried...

Embodiment 3

[0028] Sodium silicate solution (Na 2 O: 90g / L; SiO 2 : 250g / L), sodium aluminate is dissolved in NaOH solution to configure sodium aluminate solution (Na 2 O: 120g / L; AL 2 o 3 : 40g / L). The above two solutions are prepared according to the silicon-aluminum molar ratio of 6:1, the flow rate of the sodium aluminate solution is 6L / h, and the flow rate of the sodium silicate solution is 3.39L / h. The mixed reaction is gelled, and after passing through the aging tank, it is pumped into a temperature-controllable tubular flow crystallization reactor for crystallization (heating to 95°C, flow rate 0.1m / min, residence time 15min). After crystallization, the mother liquor is removed by a continuous filter washing device and the pH value is washed with deionized water to 7 (the filtered mother liquor is reused in the preparation of sodium aluminate solution). Finally, it is dried into powder by drying equipment at 300°C to obtain a submicron 4A zeolite product. Others are with emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com