Technological process and special apparatus for preparing 4A zeolite

A zeolite and process technology, applied in the field of 4A zeolite synthesis, to achieve the effect of narrow particle size distribution, perfect crystal shape and small device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

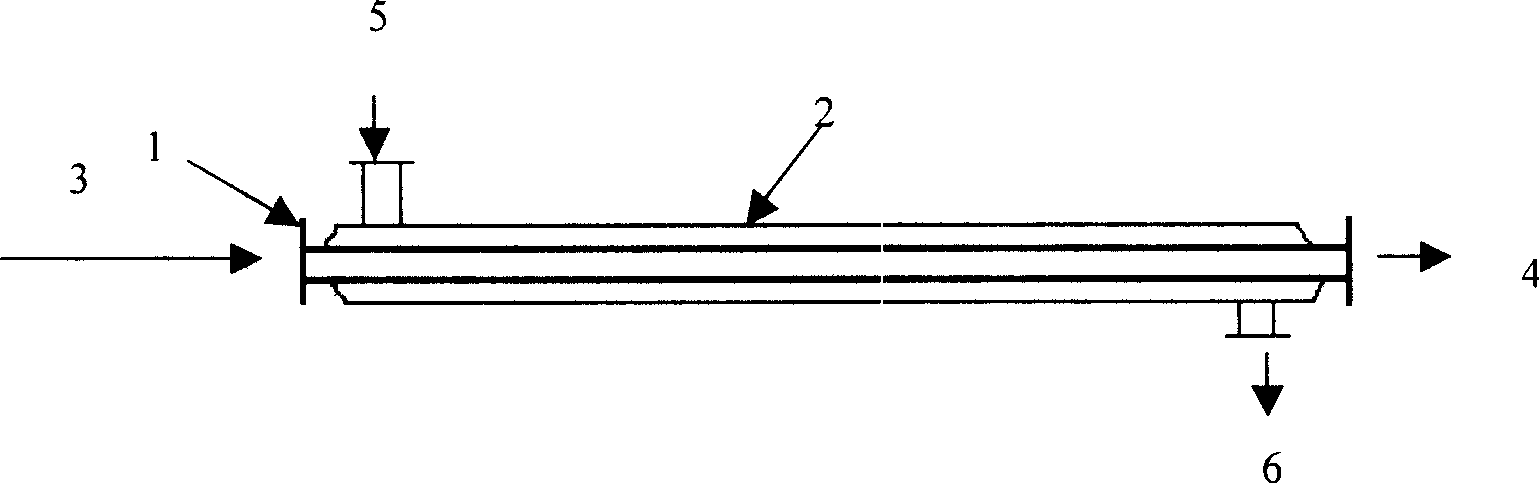

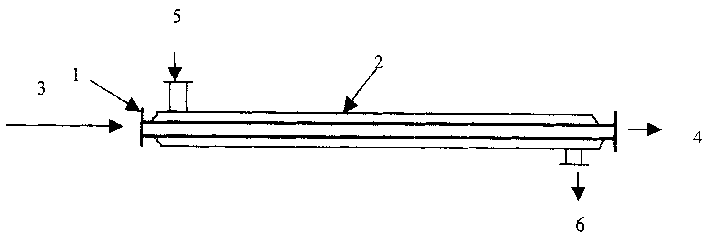

[0019] Sodium silicate solution (Na 2 O: 45g / l; SiO 2 : 120g / l), sodium aluminate is dissolved in NaOH solution to configure sodium aluminate solution (Na 2 O: 90g / l; Al 2 o 3 : 60g / l). The heating medium enters the heating tube 2 from the heating medium inlet 5, flows out from the heating medium outlet 6, and heats up to 75°C. The above two solutions are continuously entered into the mixing reactor through the pipeline to carry out the mixing reaction gelling according to the molar ratio of silicon to aluminum being 2, and then enter the material pipe 1 of the continuous sleeve type crystallizer from the material inlet 3 at a flow rate of 0.5m / min, Stay in material pipe 1 for 30 minutes. After crystallization, it flows out from the material outlet 4, and the mother liquor is removed by a continuous filter washing device, and the pH value is washed with deionized water to 8, and the filtered mother liquor is reused in the preparation of sodium aluminate solution. Finally...

Embodiment 2

[0021] Dissolve sodium silicate in water to form sodium silicate solution (Na 2 O: 75g / l; SiO 2 : 180g / l), alumina colloid is dissolved in NaOH solution to form sodium aluminate solution (Na 2 O: 70g / l; Al 2 o 3 : 40g / l). The heating medium enters the heating tube 2 from the heating medium inlet 5, flows out from the heating medium outlet 6, and heats up to 85°C. Above-mentioned two kinds of solutions are 5 according to the silicon-aluminum molar ratio, respectively enter the mixing reactor continuously through the pipeline and carry out the mixing reaction gelation, then enter the material pipe 1 of the continuous casing type crystallizer from the material inlet 3 with the flow rate 1m / min, in Material pipe 1 stays for 30min. After crystallization, it flows out from the material outlet 4, and the mother liquor is removed by a continuous filter washing device, and the pH value is washed with deionized water to 10, and the filtered mother liquor is reused in the preparatio...

Embodiment 3

[0023] Sodium silicate solution (Na 2 O: 90g / l; SiO 2 : 250g / l), sodium aluminate is dissolved in NaOH solution to configure sodium aluminate solution (Na 2 O: 120g / l; Al 2 o 3 : 40g / l). The heating medium enters the heating tube 2 from the heating medium inlet 5, flows out from the heating medium outlet 6, and heats up to 95°C. The above two solutions are continuously entered into the mixing reactor through the pipeline to carry out the mixing reaction gelation according to the silicon-alumina molar ratio of 6, and then enter the material pipe 1 of the continuous casing type crystallizer from the material inlet 3 at a flow rate of 0.1m / min, Stay in material pipe 1 for 15 minutes. After crystallization, it flows out from the material outlet 4, and the mother liquor is removed by a continuous filter washing device, and the pH value is washed with deionized water to 8, and the filtered mother liquor is reused in the preparation of sodium aluminate solution. Finally, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com