Production method of 8.7/10kV and below mining monitor rubber jacketed flexible cable

A production method and flexible cable technology, applied in the direction of conductor/cable insulation, insulated cables, bendable cables, etc., can solve urgent problems, lack of mass production supporting industries, increase of voltage level of underground transformers, etc., and achieve increased working capacity , Guarantee the effect of partial discharge level and withstand voltage level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

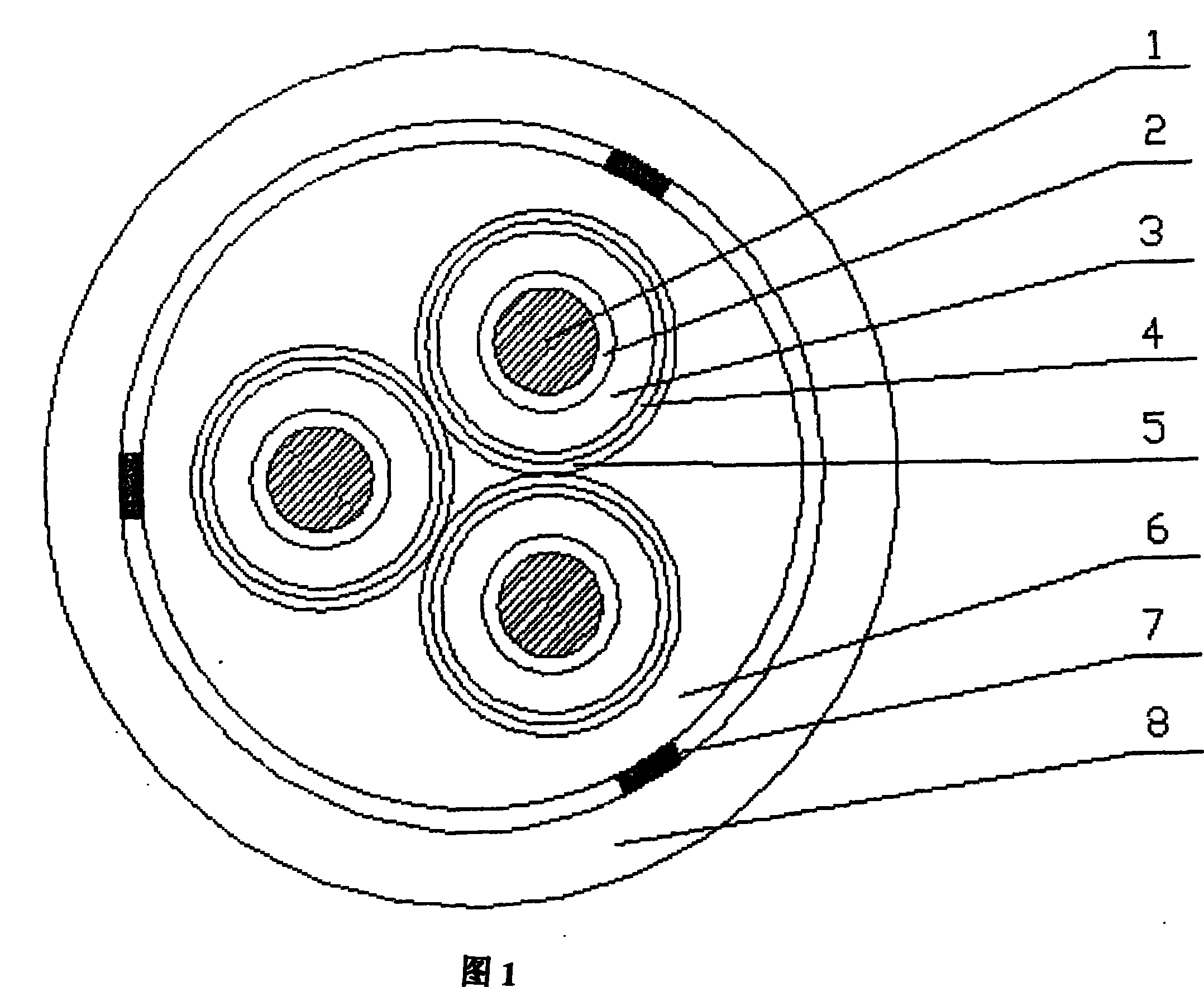

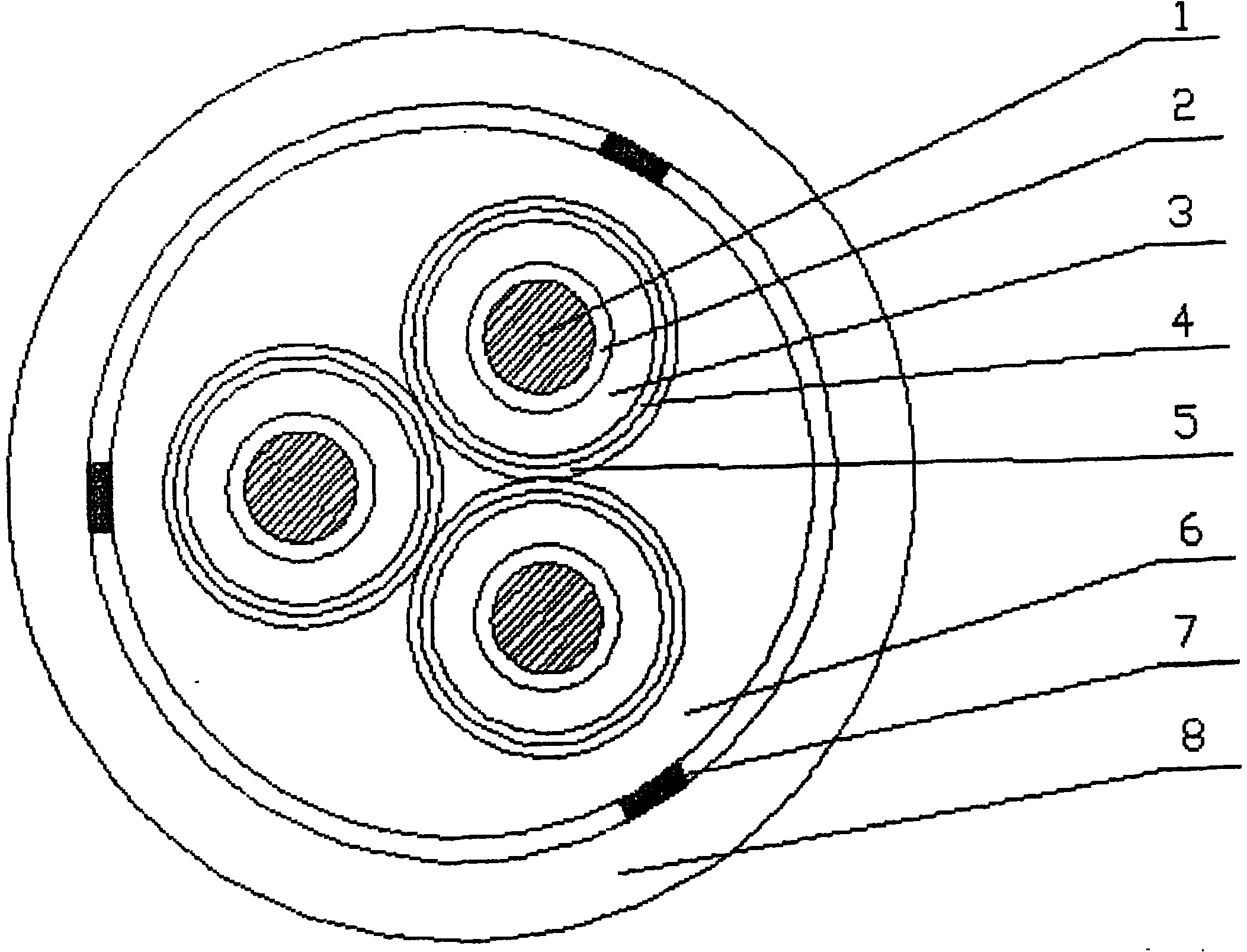

[0033] Below in conjunction with accompanying drawing, the present invention will be further described:

[0034] Such as figure 1 As shown, the 6 / 10kV and 8.7 / 10kV mine monitoring rubber-sheathed flexible cable of the present invention includes a power core flexible conductor 1, a conductive rubber inner shielding layer 2, an insulating layer 3 made of high-voltage ethylene-propylene rubber, Conductive rubber outer shielding layer 4, copper wire braided shielding layer 5, rubber inner sheath 6, rubber outer sheath 8, between the rubber inner sheath 6 and rubber outer sheath 8 there is a monitoring wire core and a semi-conductive wrapping tape The monitoring core layer consists of 7 layers.

[0035] The production method of the cable comprises the following steps:

[0036] 1. Firstly, the stranded flexible conductor 1 is extruded through the catenary three-layer continuous vulcanization production line at one time, layered and formed at one time to extrude the inner shielding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com