Thyristor resistor transition switching on-load tap-changer

A technology of changeover switch and on-load tap, which is applied in the direction of electronic switches, circuits, inductors, etc., to achieve the effects of reliable operation, reduced workload and cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

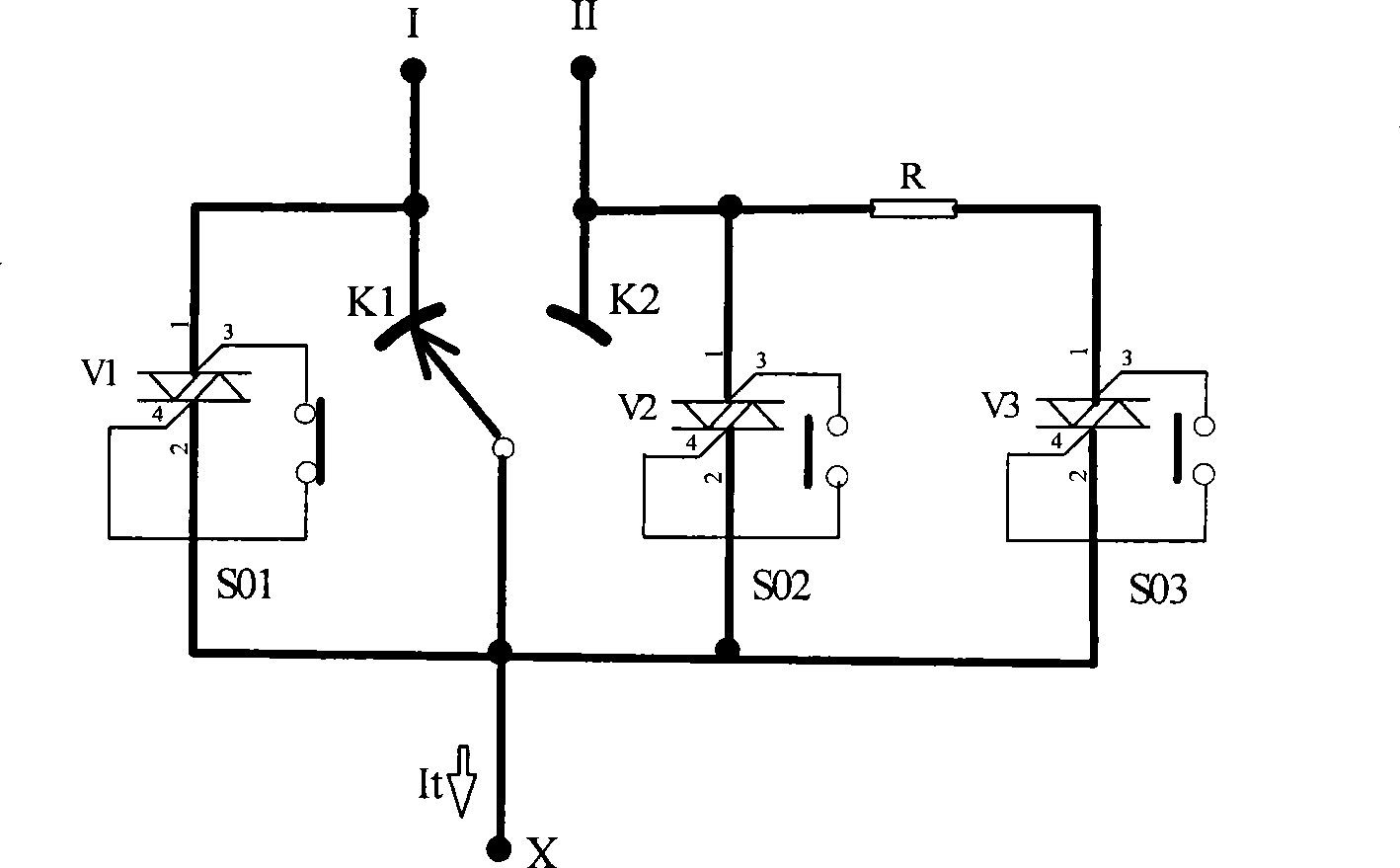

[0025] This embodiment describes a thyristor resistance transition combination on-load tap changer, which includes a switching circuit, and the switching circuit includes a thyristor switching circuit, a transition resistance branch formed by a transition thyristor switch and a transition resistance.

[0026] see figure 1 A thyristor changeover switch branch is connected to the fixed contacts of the odd-number tap and the even-number tap, and a transition resistance branch composed of a transition thyristor switch and a transition resistor is connected to the even-number tap side.

[0027] When switching, first connect the gate of the corresponding thyristor, so that the thyristor connects the transition resistance branch and passes the transformer current between the original tap and the new tap; then disconnect the two thyristor switches connected in series in the transition resistance branch as required. One gate circuit can complete the switching from the original tap to t...

Embodiment 2

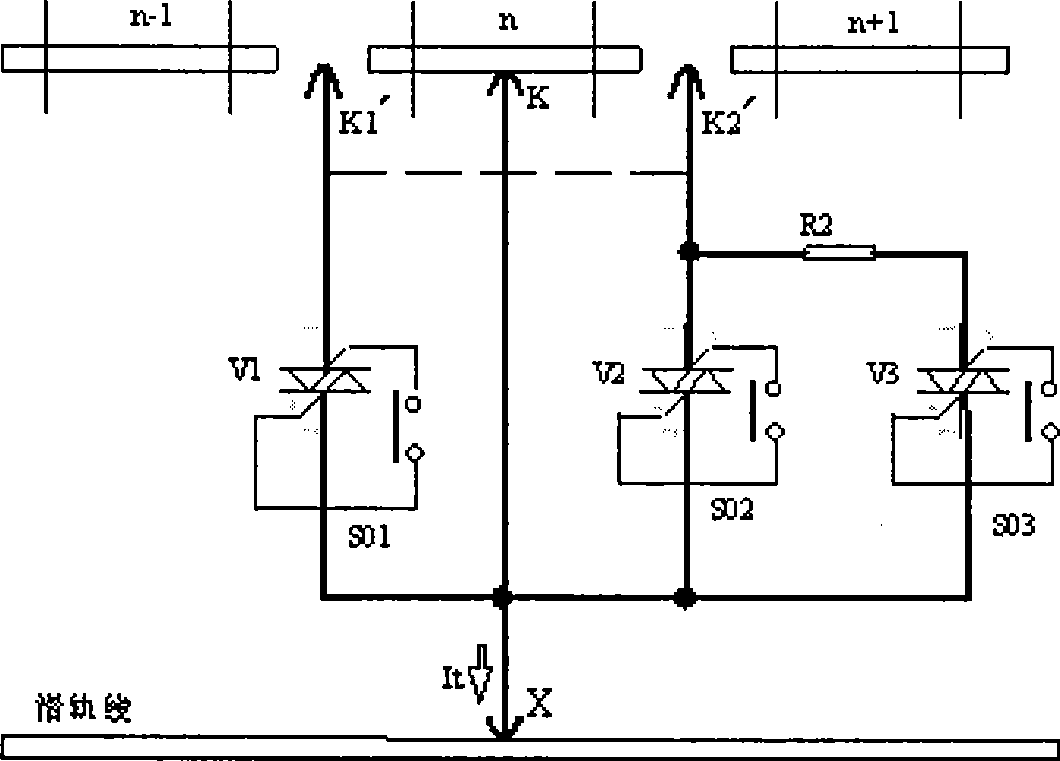

[0037] This embodiment describes the thyristor resistance transition compound on-load tap-changer (see figure 2 ). Both transition moving contacts are connected with a thyristor changeover switch branch, and one of the moving contacts is also connected with a transition resistance branch. When the moving contact moves to the switching position, first connect the gate of the relevant thyristor switch, so that the thyristor switch connects the transition resistance branch and passes the transformer current between the original tap and the new tap; and then disconnects the thyristor switch as required The gate circuit of one of the two thyristor switches connected in series in the transition resistance branch can complete the switching from the original tap to the new tap when the transformer current appears to cross zero. It is not necessary to consider the zero-crossing point of the current when turning on and off the gate circuit of the thyristor switch, and the gate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com