Efficient energy saving method for driving LED (light-emitting diode) by high frequency and narrow pulse

A high-efficiency, energy-saving, narrow-pulse technology, applied in the field of electric light sources, can solve the problems affecting the life and efficiency of LED light sources, and LED heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

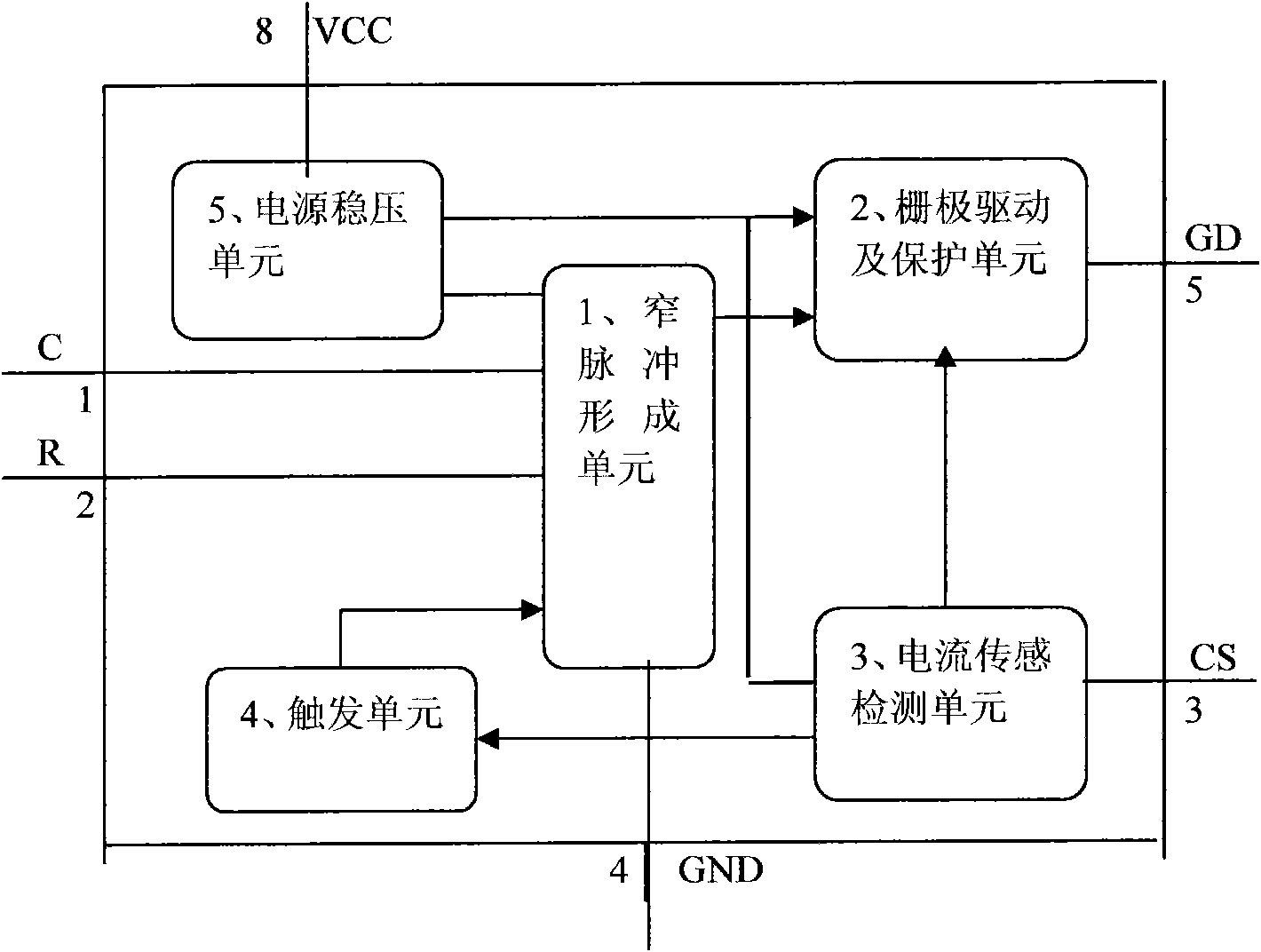

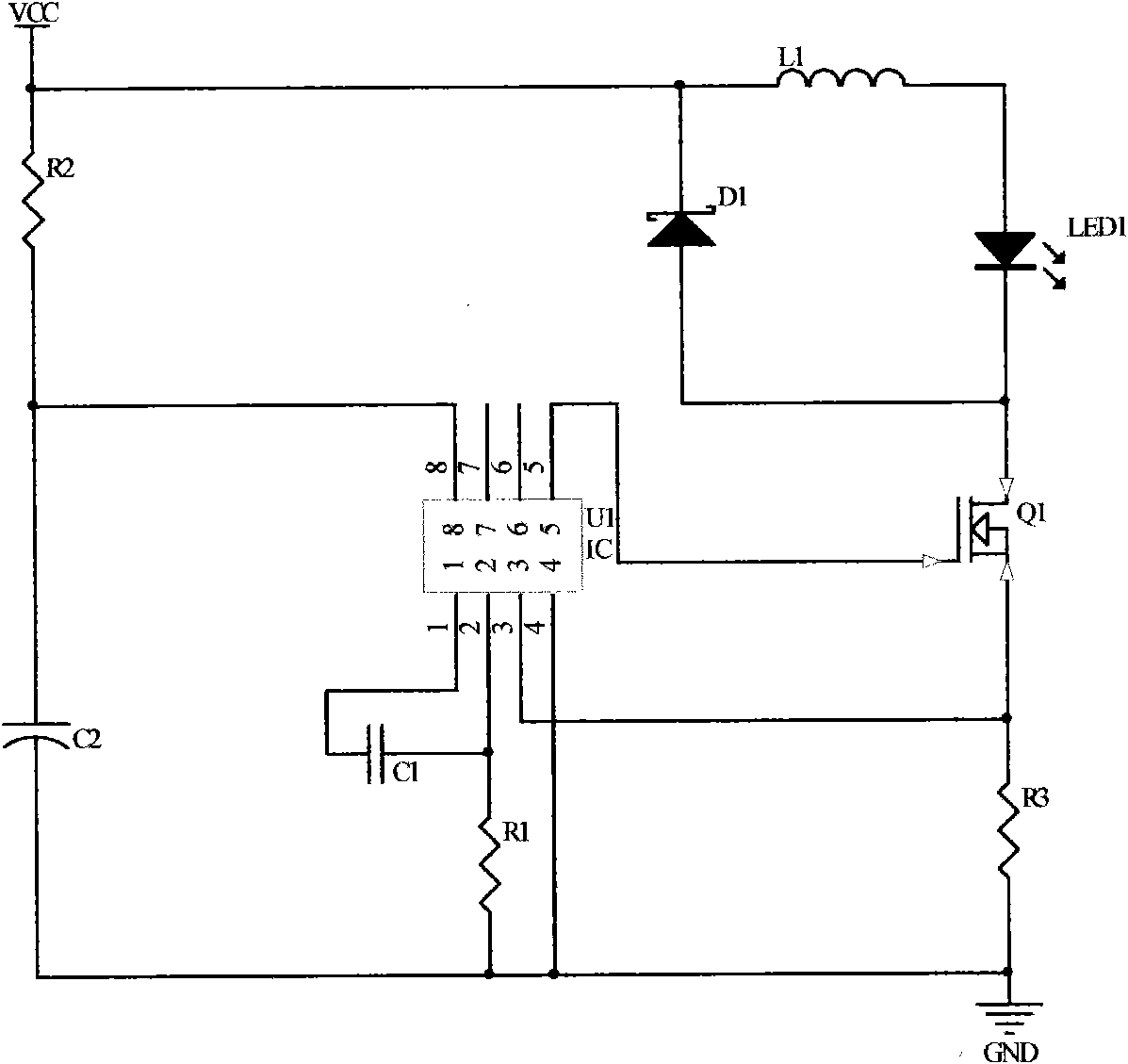

[0018] Attached below figure 2 and one A high-frequency narrow-pulse driving LED embodiment will further illustrate the present invention.

[0019] According to the principle of the method of the present invention, a high-frequency narrow-pulse LED driver chip is packaged in an S0-8 package U1, the first pin C of U1 is connected to the left end of the timing capacitor C1; the second pin R of U1 is connected to the timing capacitor The right end of C1 and the upper end of the timing resistor R1; the 4th pin of U1 is connected to the lower end of R1 and grounded to GND; the 8th pin of U1 is connected to the lower end of the current limiting resistor R2 and the positive pole of the filter capacitor C2; the negative pole of C2 is grounded to GND; the upper end of the resistor R2 is connected to To the positive pole of the DC power supply VCC; the negative pole of the DC power supply is grounded to GND; the 5th pin GD of U1 is connected to the gate G of the external MOS switch Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com