A kind of mold roasting method of aluminum frame anode

An anode and aluminum frame technology, applied in the field of aluminum electrolysis, can solve problems affecting the firing start-up of the electrolytic cell, uneven anode current distribution, and long time for raising the current of the whole series, so as to achieve a safe and stable roasting process, uniform current distribution, and smooth roasting. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A casting mold baking method for an aluminum frame anode, comprising the following steps:

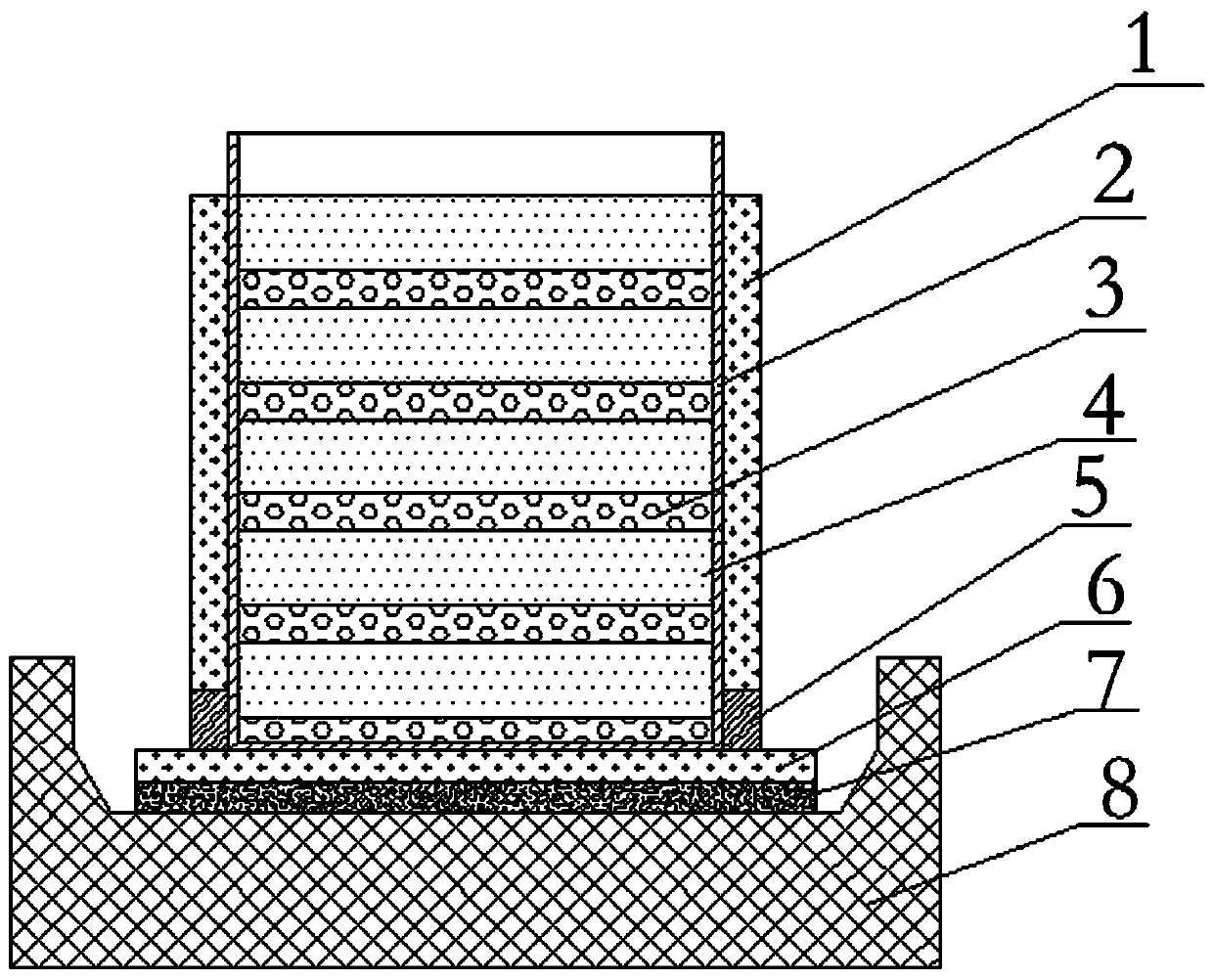

[0025] a. Lay coke particles 7 on the upper surface of the cathode 8 of the aluminum electrolytic cell;

[0026] b. Lay metal aluminum 6 on the coke grains 7 paved in step a;

[0027] c. Place an aluminum frame anode with a conductor 4 and a carbon material 3 on the metal aluminum 6;

[0028] d. Vertically arrange several anode guide rods 1 around the aluminum frame anode;

[0029] e. The anode of the aluminum frame is energized and roasted until the start-up requirements of the electrolytic cell are met.

[0030] The coke particles 7 are any one or any combination of calcined petroleum coke, pitch coke and graphite in any proportion.

[0031] The shape of the coke particles 7 is granular or powdery or a mixture of granular and powdery.

[0032] The shape of the metal aluminum 6 is plate shape, block shape, granular shape, chip shape or a mixture of any several shapes.

[00...

Embodiment 2

[0035] A casting mold baking method for an aluminum frame anode, comprising the following steps:

[0036] a, paving petroleum coke on the upper surface of the cathode 8 of the aluminum electrolytic cell;

[0037] B, lay aluminum plate on the petroleum coke laid in step a;

[0038] c. Place an aluminum frame anode with a conductor 4 and a carbon material 3 on the aluminum plate;

[0039] d. Vertically set several anode guide rods 1 around the aluminum frame anode; set a shunt block 5 around the aluminum frame anode, the shunt block 5 connects the aluminum frame anode and the aluminum plate, and the shunt block 5 is an aluminum block.

[0040] e. The aluminum frame anode is energized and roasted. After the full current is applied for 24 hours, the shunt block 5 is taken out from the electrolytic cell, and the casting and roasting speed of the aluminum frame anode is accelerated until the start-up requirement of the electrolytic cell is met.

Embodiment 3

[0042] A casting mold baking method for an aluminum frame anode, comprising the following steps:

[0043] a. Lay a mixture of petroleum coke, pitch coke and graphite on the upper surface of the cathode 8 of the aluminum electrolytic cell;

[0044] B, lay aluminum plate on the mixture of petroleum coke, pitch coke, graphite laid in step a;

[0045] c. Place an aluminum frame anode with a conductor 4 and a carbon material 3 on the aluminum plate, and fill the gap between the aluminum plate and the aluminum frame anode with aluminum debris;

[0046] d. Several anode guide rods 1 are vertically arranged around the aluminum frame anode, and a diverter block 5 is also arranged at the bottom end of the anode guide rod 1. The diverter block 5 is connected to the anode guide rod and the aluminum plate, and the diverter block 5 is carbon materials;

[0047] e. The anode of the aluminum frame is energized and roasted. After 36 hours of full current, the shunt block 5 is taken out from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com