Molding calcination method for aluminum frame anode

An anode and aluminum frame technology, which is applied in the field of aluminum electrolysis, can solve the problems of affecting the roasting start-up work of the electrolytic cell, the long time to raise the whole series of current, and the uneven distribution of anode current, so as to achieve a safe and stable roasting process, low roasting cost, and current Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A casting mold baking method for an aluminum frame anode, comprising the following steps:

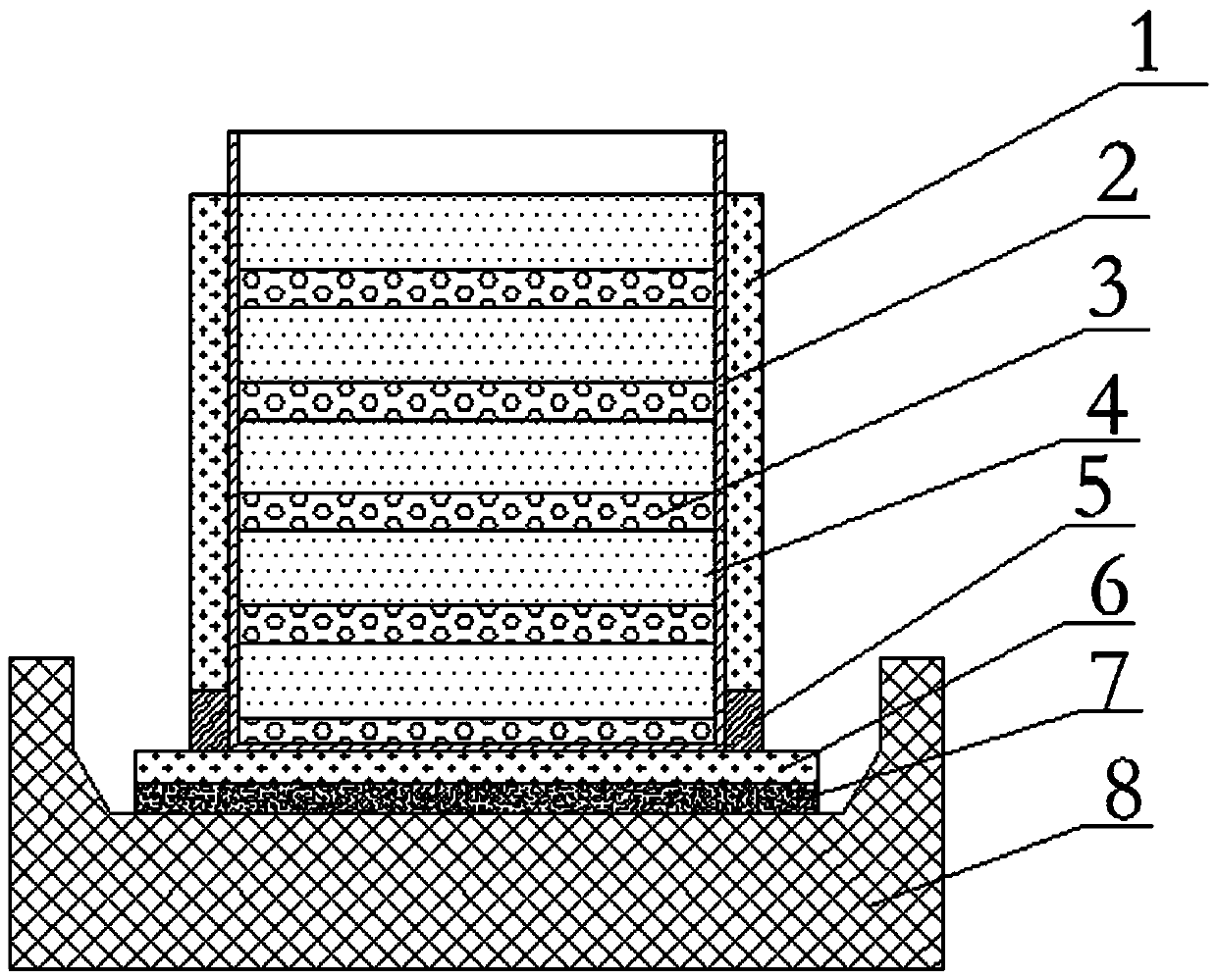

[0025] a. Lay coke particles 7 on the upper surface of the cathode 8 of the aluminum electrolytic cell;

[0026] b. Lay metal aluminum 6 on the coke grains 7 paved in step a;

[0027] c. Place an aluminum frame anode with a conductor 4 and a carbon material 3 on the metal aluminum 6;

[0028] d. Vertically arrange several anode guide rods 1 around the aluminum frame anode;

[0029] e. The anode of the aluminum frame is energized and roasted until the start-up requirements of the electrolytic cell are met.

[0030] The coke particles 7 are any one or any combination of calcined petroleum coke, pitch coke and graphite in any proportion.

[0031] The shape of the coke particles 7 is granular or powdery or a mixture of granular and powdery.

[0032] The shape of the metal aluminum 6 is plate shape, block shape, granular shape, chip shape or a mixture of any several shapes.

[00...

Embodiment 2

[0035] A casting mold baking method for an aluminum frame anode, comprising the following steps:

[0036] a, paving petroleum coke on the upper surface of the cathode 8 of the aluminum electrolytic cell;

[0037] B, lay aluminum plate on the petroleum coke laid in step a;

[0038] c. Place an aluminum frame anode with a conductor 4 and a carbon material 3 on the aluminum plate;

[0039] d. Vertically set several anode guide rods 1 around the aluminum frame anode; set a shunt block 5 around the aluminum frame anode, the shunt block 5 connects the aluminum frame anode and the aluminum plate, and the shunt block 5 is an aluminum block.

[0040] e. The aluminum frame anode is energized and roasted. After the full current is applied for 24 hours, the shunt block 5 is taken out from the electrolytic cell, and the casting and roasting speed of the aluminum frame anode is accelerated until the start-up requirement of the electrolytic cell is met.

Embodiment 3

[0042] A casting mold baking method for an aluminum frame anode, comprising the following steps:

[0043] a. Lay a mixture of petroleum coke, pitch coke and graphite on the upper surface of the cathode 8 of the aluminum electrolytic cell;

[0044] B, lay aluminum plate on the mixture of petroleum coke, pitch coke, graphite laid in step a;

[0045] c. Place an aluminum frame anode with a conductor 4 and a carbon material 3 on the aluminum plate, and fill the gap between the aluminum plate and the aluminum frame anode with aluminum debris;

[0046] d. Several anode guide rods 1 are vertically arranged around the aluminum frame anode, and a diverter block 5 is also arranged at the bottom end of the anode guide rod 1. The diverter block 5 is connected to the anode guide rod and the aluminum plate, and the diverter block 5 is carbon materials;

[0047] e. The anode of the aluminum frame is energized and roasted. After 36 hours of full current, the shunt block 5 is taken out from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com