Aerosol particle sensor with axial fan

一种传感器、风扇的技术,应用在气流系统领域,能够解决没有成本优势、不可能所有采样位置实时监测等问题,达到降低成本、系统装置简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In this disclosure, the term "light" is not limited to visible radiation, but is used in a broad sense to refer to any electromagnetic radiation, including infrared, ultraviolet, extreme ultraviolet and x-ray radiation. It should be noted that the particle sensors and particle counters disclosed in this specification are designed to detect free single particles in a flowing gas, which distinguishes them from the detection and analysis of particles in the gas itself, in a cloud of particles suspended in a gas, or in a gas In other systems such as confined particles that are constrained to flow in a line through a beam of light. Those of ordinary skill in the art will recognize that detecting and determining the size of free-flowing single particles in gases is a much more difficult task, especially for particles less than 1 micron in size; Different technologies than analysis systems.

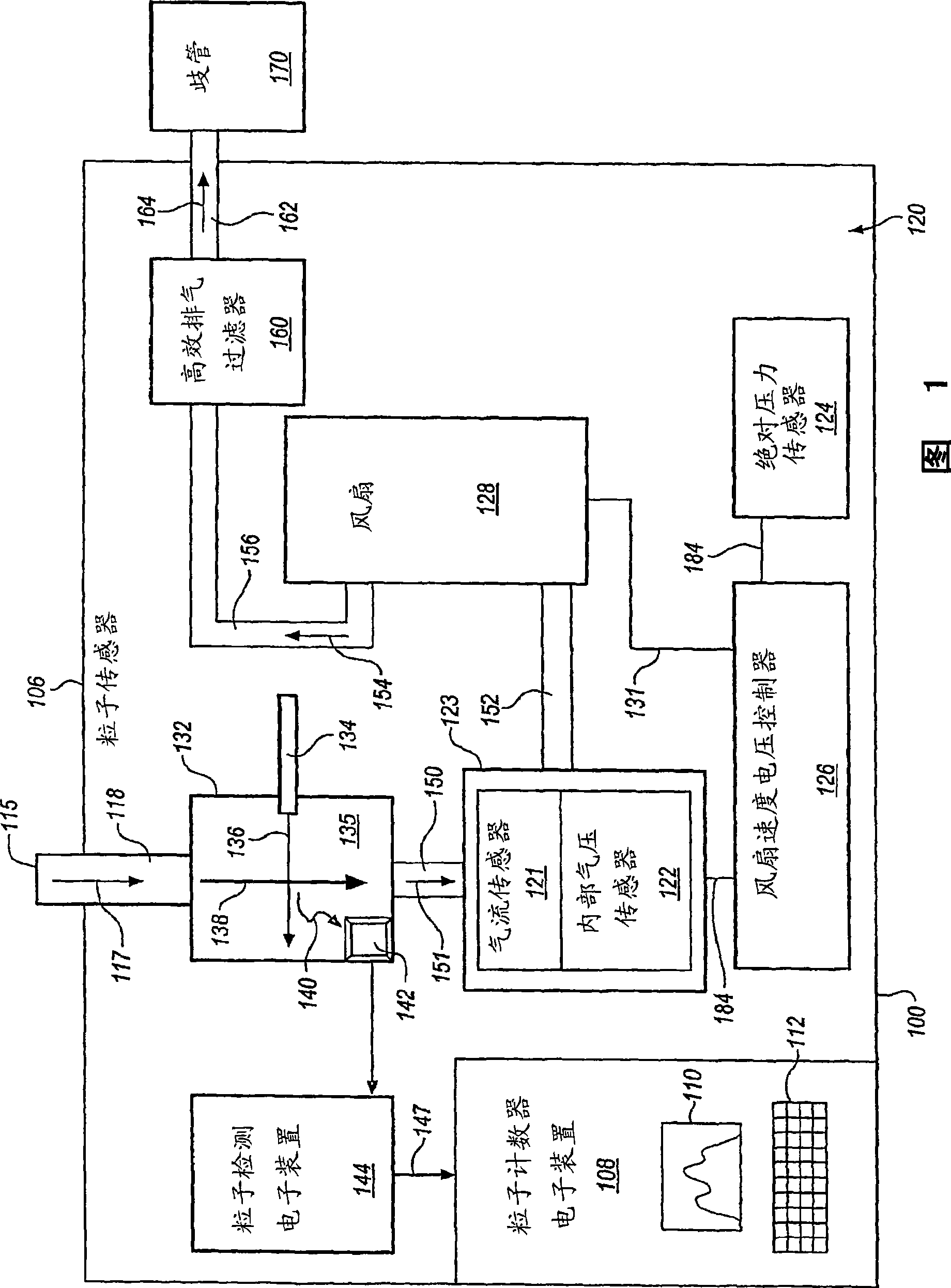

[0029] Aerosol counter or sensor instruments utilize high static pressure fans or co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com