Fault prewarning trailer axle

A fault warning and axle technology, applied in the directions of axles, wheels, vehicle parts, etc., can solve problems such as affecting road smoothness, delaying delivery time, brake drum rupture, etc. The effect of implementing and reducing breakdown maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

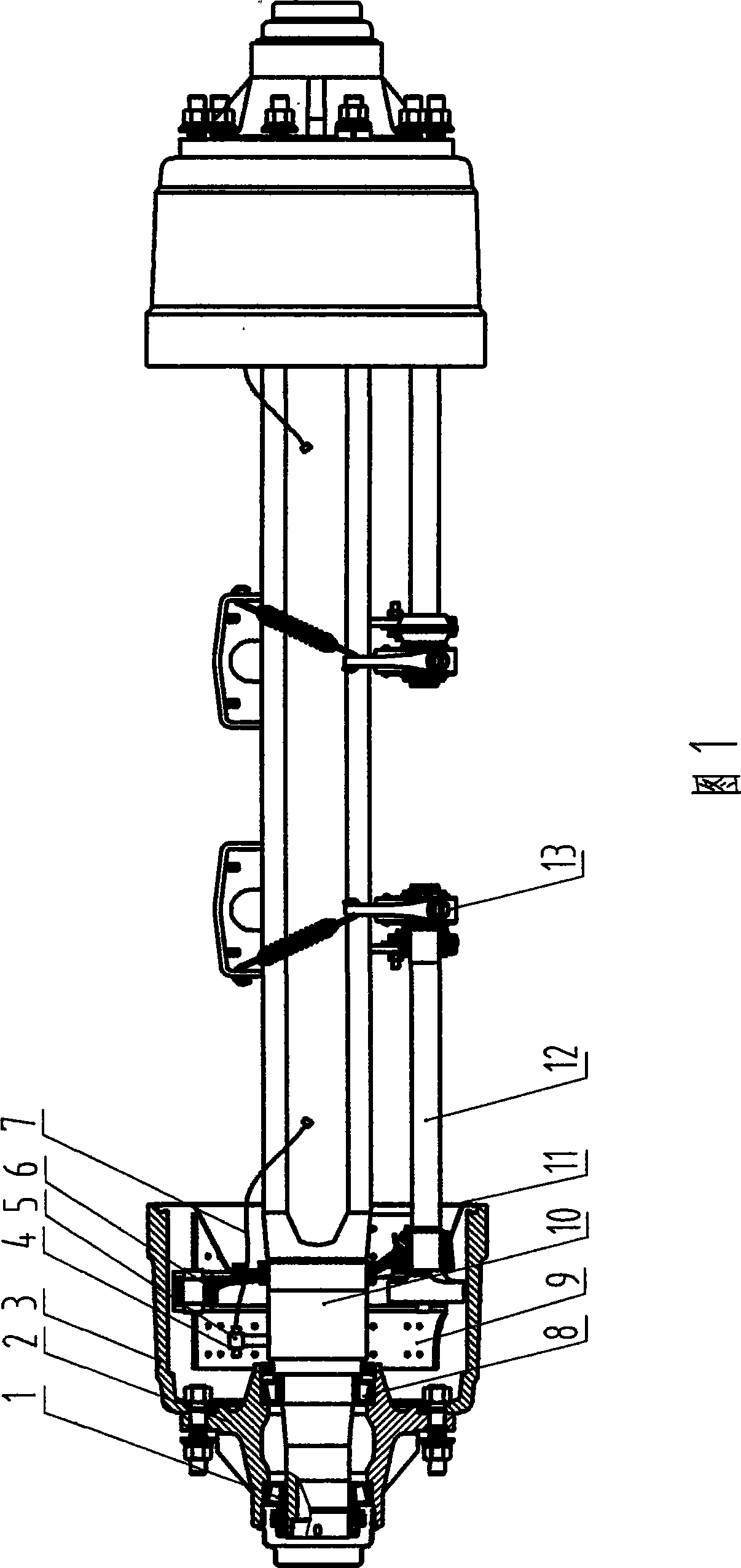

[0008] It can be seen from Figure 1 that the present invention is the axle 10, the outer bearing 1, the inner bearing 8, the hub 2, the brake drum 3, the brake base plate 6, the brake pad 9, the dust cover 11, the camshaft 12, and the adjusting arm 13. composition. The two ends of the axle 10 are fitted with outer bearing 1 and inner bearing 8, the hub 2 is fitted on the outer bearing 1 and the inner bearing 8. The brake drum 3 and the hub 2 are press-fitted together by bolts; the brake pad 9 is installed on the brake bottom plate 6, The brake base plate 6 is welded to the axle 10; one end of the camshaft 12 is flexibly installed in the preset installation hole of the brake base plate 6, and the adjusting arm 13 is sleeved on the camshaft 12. The thermal sensor seat 5 is arranged in the cavity formed by the brake drum and the dust cover 11, and is fixed on the axle 10, the thermal sensor 4 is installed in the thermal sensor seat 5, and the temperature of the outer bearing 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com