Rotary vane type high pressure steering engine

A technology of rotating vane and steering gear, which is applied in the direction of rudder steering and steering, which can solve the problems of high maintenance cost, dislocation splicing, large occupied area, etc., and achieve the effect of low maintenance cost, simple sealing structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

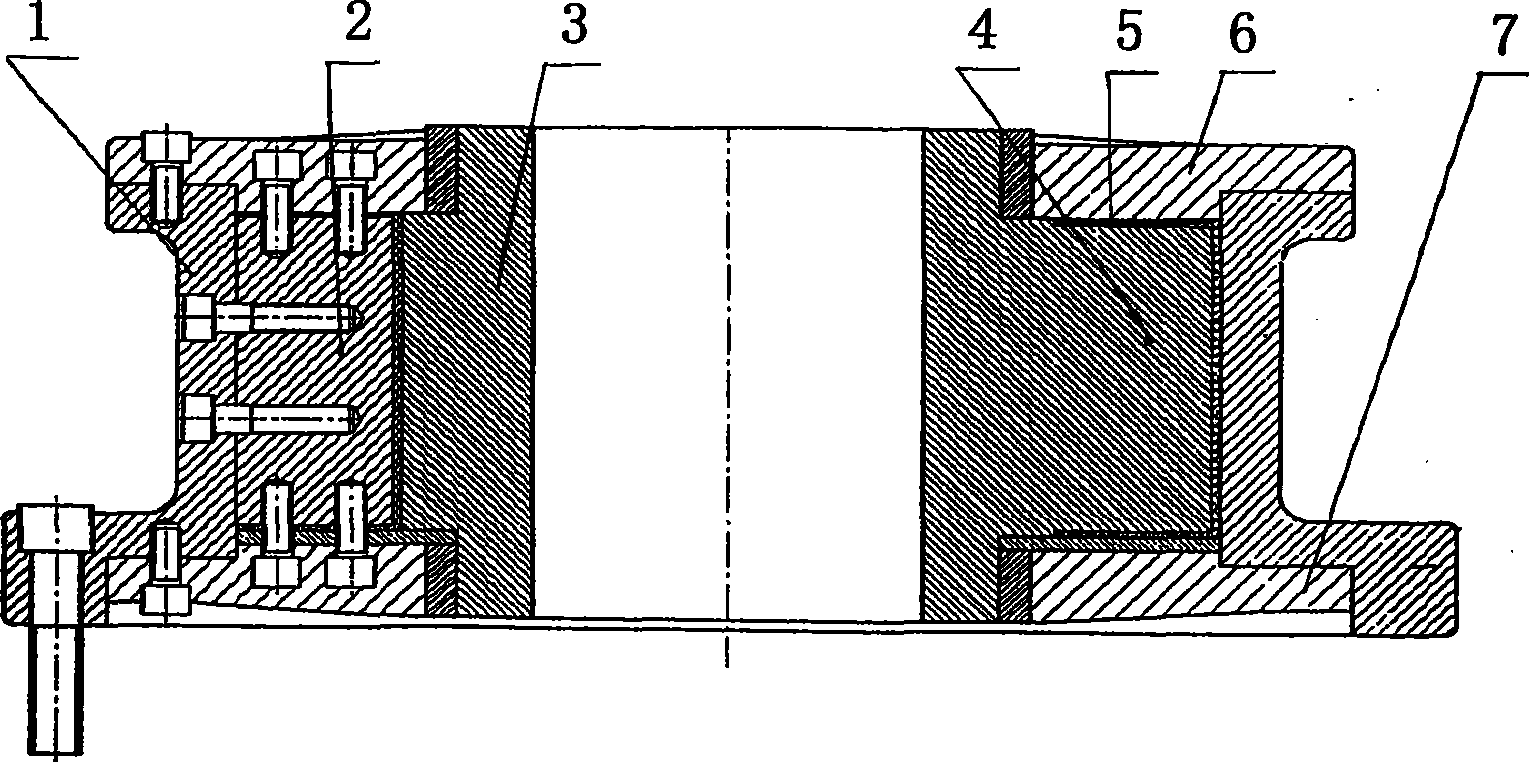

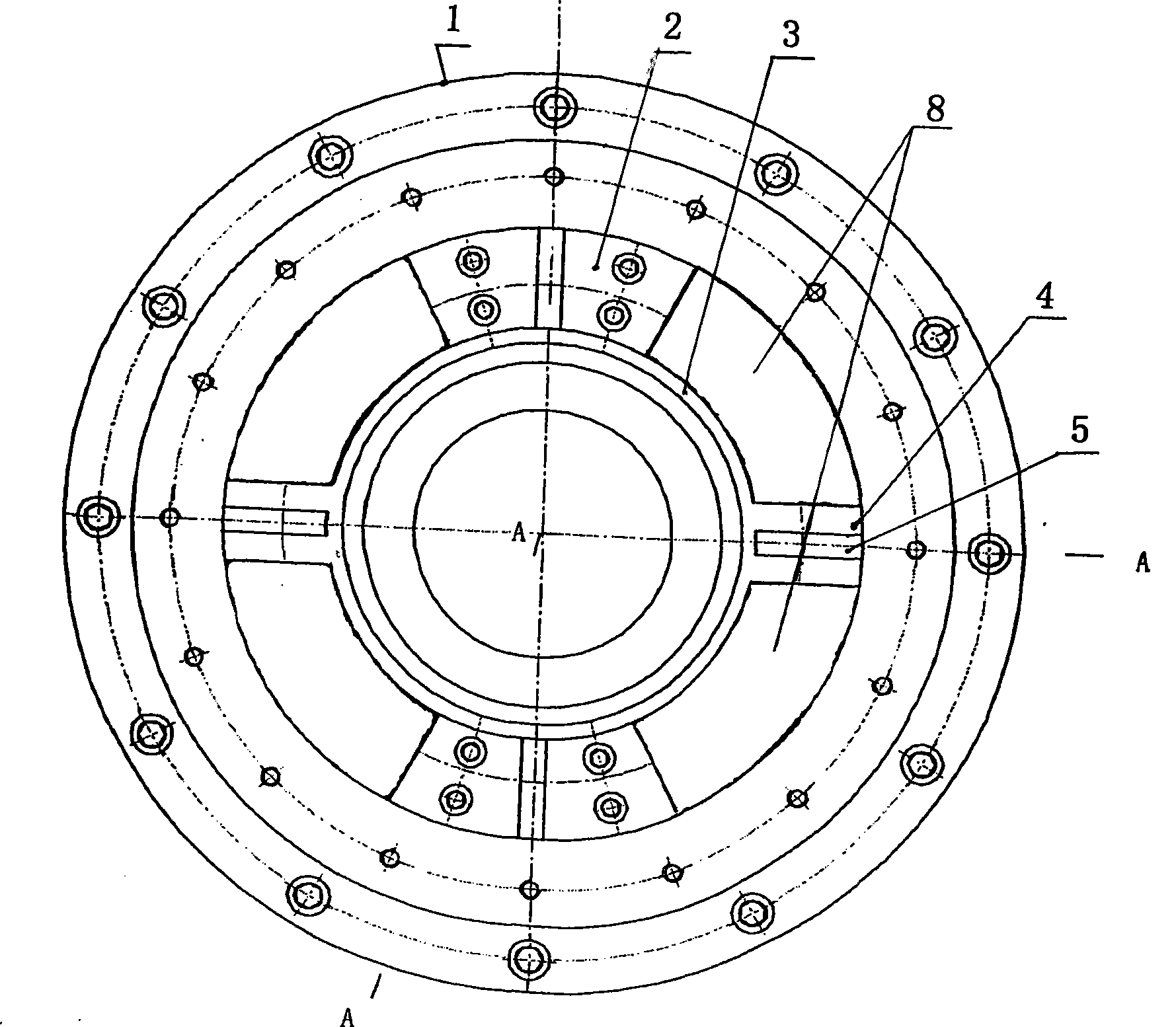

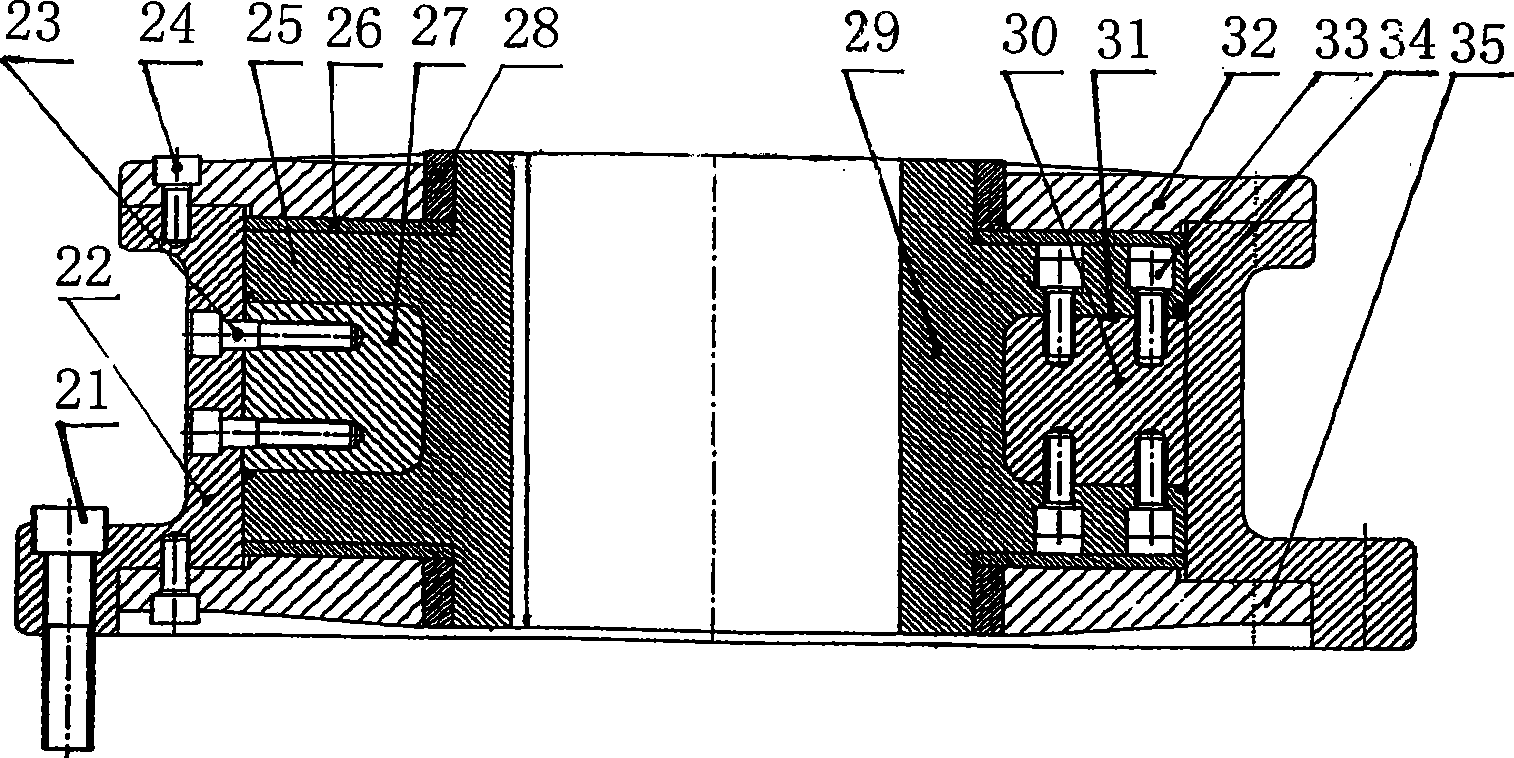

[0017] See attached Figure 3-5 In the figure, 21 is a bolt, 22 is a cylinder block, 23 is a bolt, 24 is a cover plate bolt, 25 is a round end face, 26 is a washer, 27 is a stator, 28 is a shaft sleeve, 29 is a rotating shaft, and 30 is a moving piece , 31 is the sealing strip and sealing groove, 32 is the upper cover, 33 is the bolt, 34 is the sealing ring and the sealing groove, 35 is the lower cover, 36 is the oil inlet and return chamber, 37 is the return and oil inlet chamber, 38 is the return , oil inlet, 39 are inlet and outlet holes.

[0018] The rotary blade type high-voltage steering gear of the present invention mainly includes a rotating shaft 29, a fixed piece 27, a moving piece 30, a cylinder body 22, an upper cover 32 and a lower cover 35, and the rotating shaft 29 is a coil with round end faces 25 at both ends. type rotating shaft, the cylinder body 22 is set on the round end face 25 of the wire-drum type rotating shaft, and a sealing ring 34 is installed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com