Piston for an internal combustion engine

A technology for internal combustion engines and pistons, applied in the field of internal combustion engine pistons, to achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

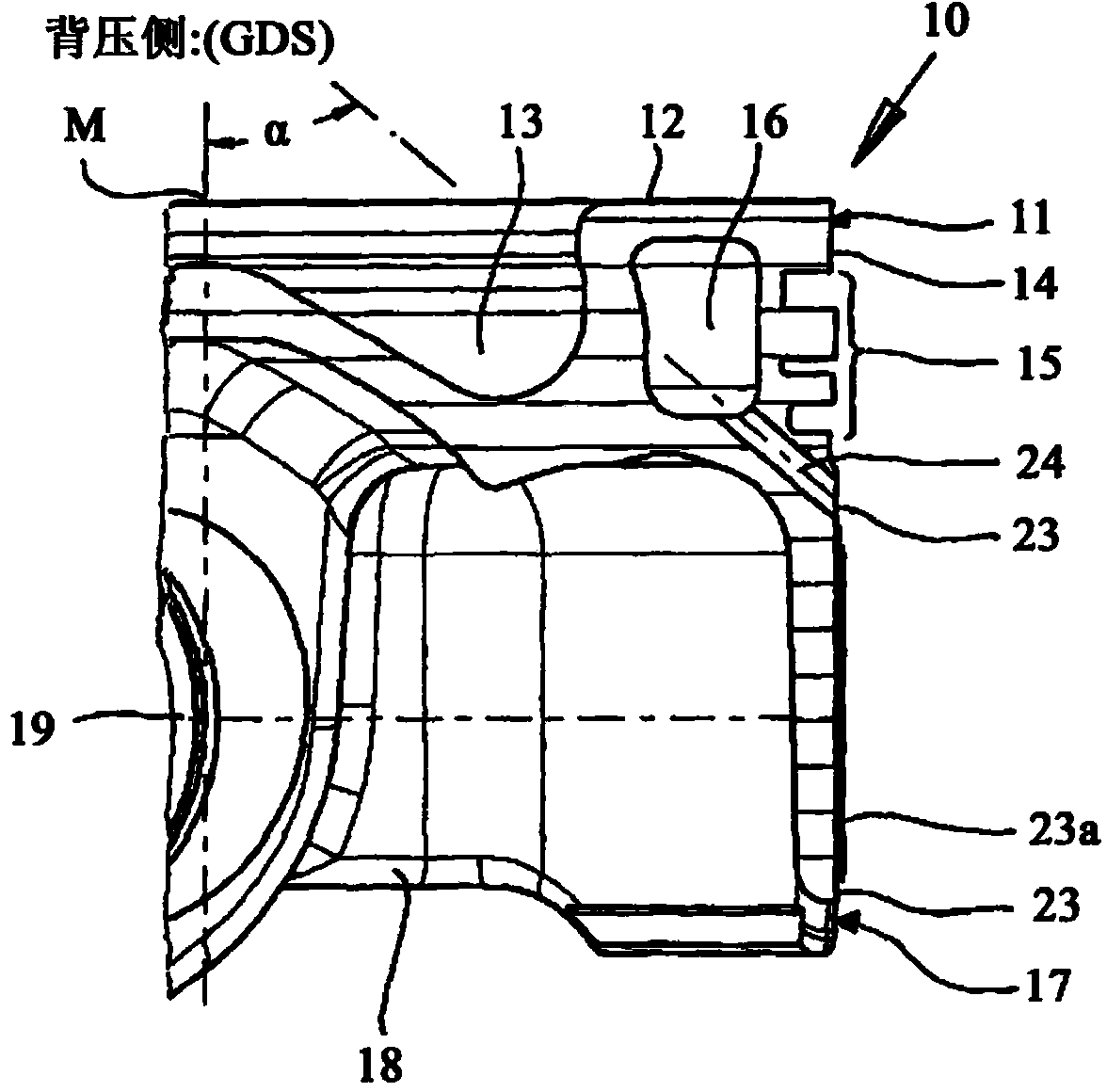

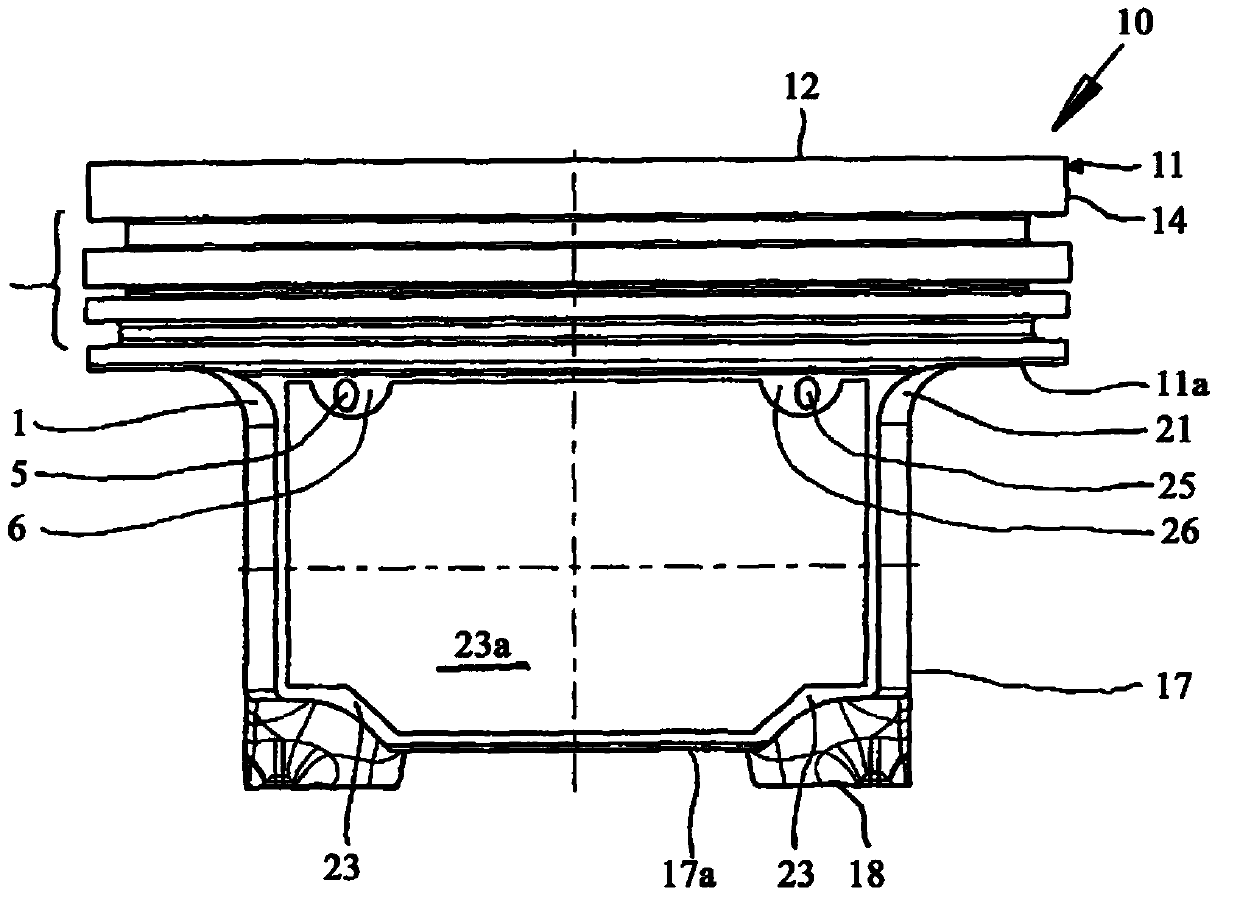

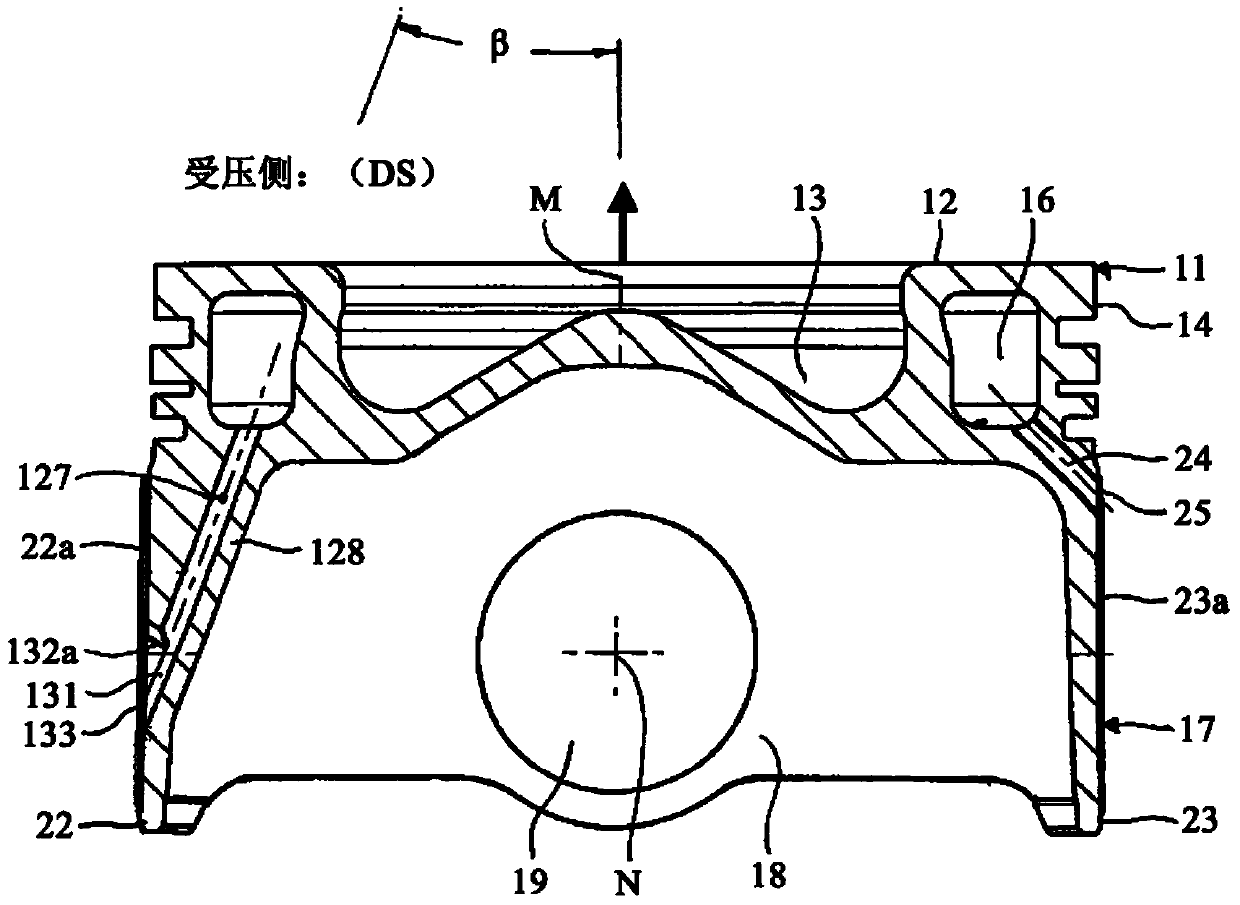

[0028] figure 1 and 2 A first embodiment of a piston 10 according to the invention is shown. Piston 10 may be a one-piece piston or a piston consisting of several parts. Piston 10 can be made of steel and / or light metal material. figure 1 and 2 A one-piece box piston 10 is shown as an example. The piston 10 has a piston head 11 with a piston crown 12 , a surrounding crown land 14 and a piston ring section 15 for receiving piston rings (not shown), the piston crown having a crown recess 13 . A circumferential cooling channel 16 is provided at the level of the piston ring part 15 . Furthermore, the piston 10 has a piston skirt 17 with a pin hub 18 and a hub bore 19 for receiving a piston pin (not shown). The pin boss 18 is connected to the underside 11 a of the piston head 11 via a pin boss connection 21 . The pin hubs 17 are connected to each other via working faces 22 , 23 . In this case the working surface 22 corresponds to the pressure side DS of the piston 10 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com