Processing method of high-cleanness stainless steel cable

A treatment method, stainless steel technology, applied in textiles, papermaking, textile cables, etc., can solve problems such as oxide skin, and achieve the effects of increasing surface pitting potential, improving corrosion resistance, and improving refraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

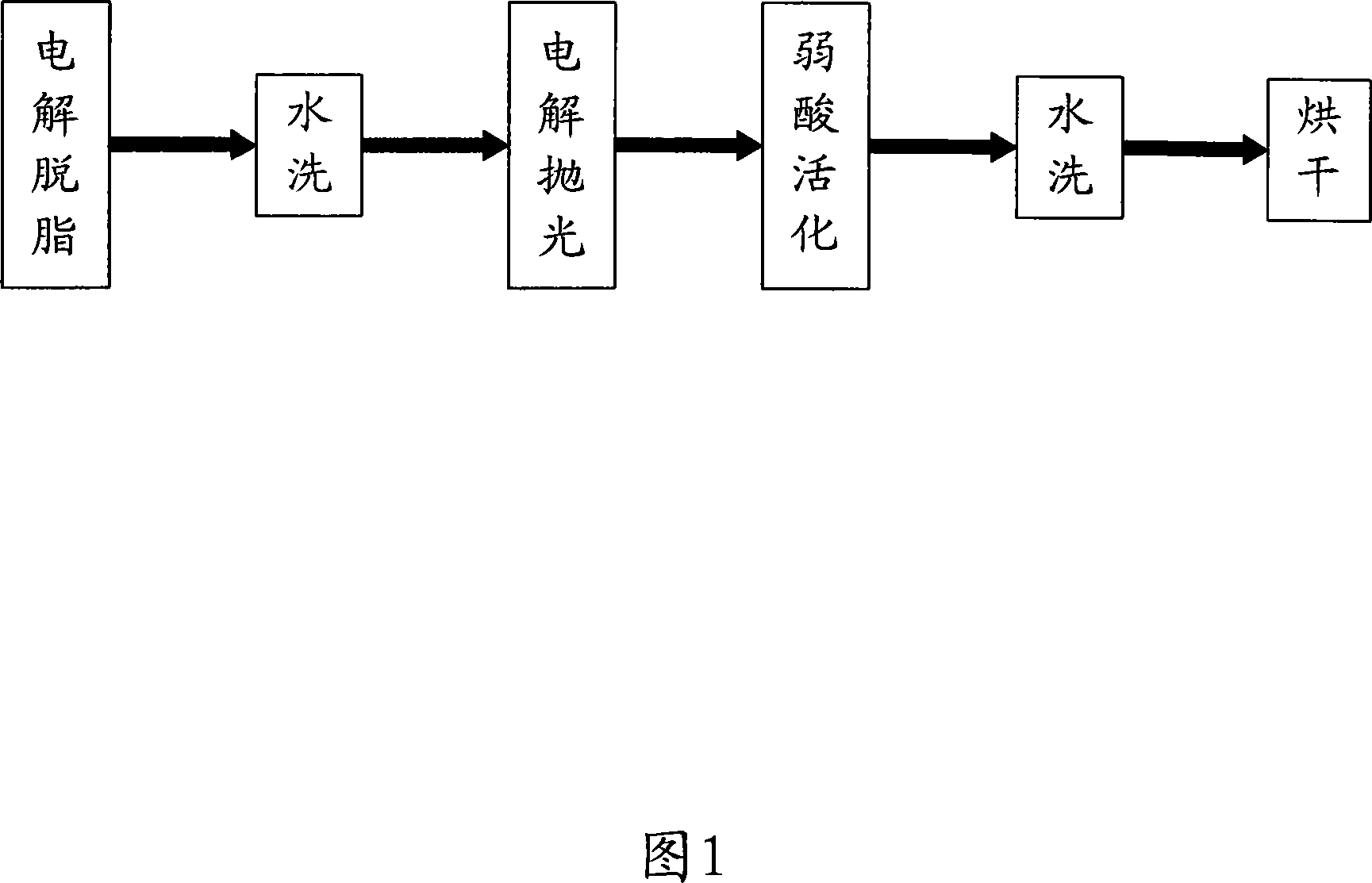

[0024] The structure of the high-clean stainless steel cable designed by the present invention and its processing method, such as figure 1 , 2 As shown, the main purpose is to achieve effective degreasing of the finished stainless steel cable manufactured by weaving stainless steel wires, and to accurately and flatly polish the rough surface caused by the processing of the stainless steel cable. Complete degreasing treatment, followed by water washing 2 to remove the degreasing agent, and then electrolytic polishing 3 of the stainless steel wire or stainless steel cable to accurately smooth and improve the rough surface of the finished product to improve the corrosion resistance of the finished product, followed by weak acid activation 4 and washing with water 5 to carry out drying 6 of the finished product, so that the surface of the stainless steel wire or stainless steel cable has better corrosion resistance characteristics and increases the luster of its surface. in,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com