Horizontal unloading construction method of tower building temporary support girders

A technology for temporary support and tower construction, which is applied in construction, building structure, and construction material processing, etc. It can solve the problem of jack loosening and synchronous operation with many operators, difficulty in making and installing reaction frame, and difficulty in personnel operation, etc. problems, to achieve obvious unloading effect, uniform and simultaneous stress release, and reduce the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

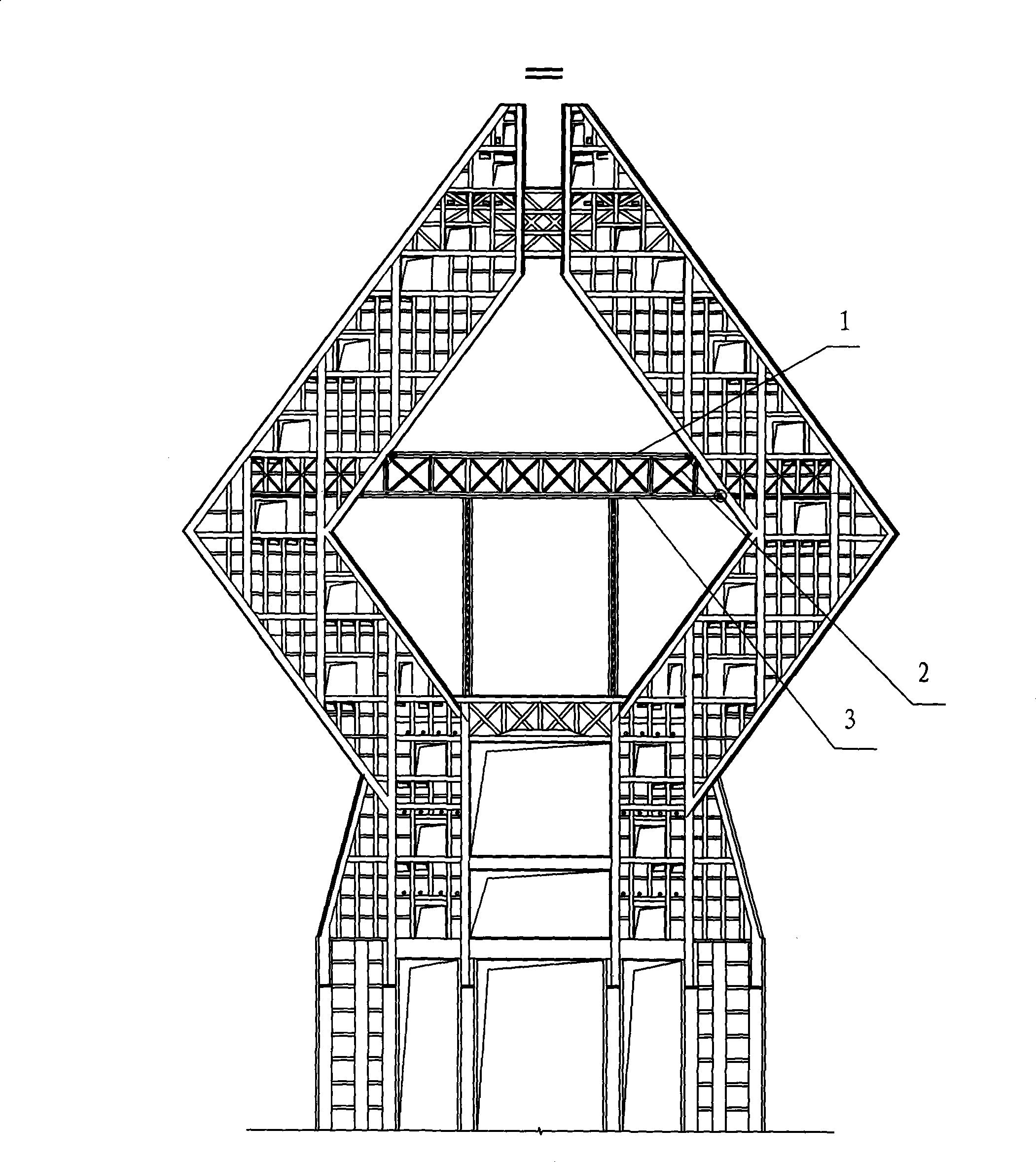

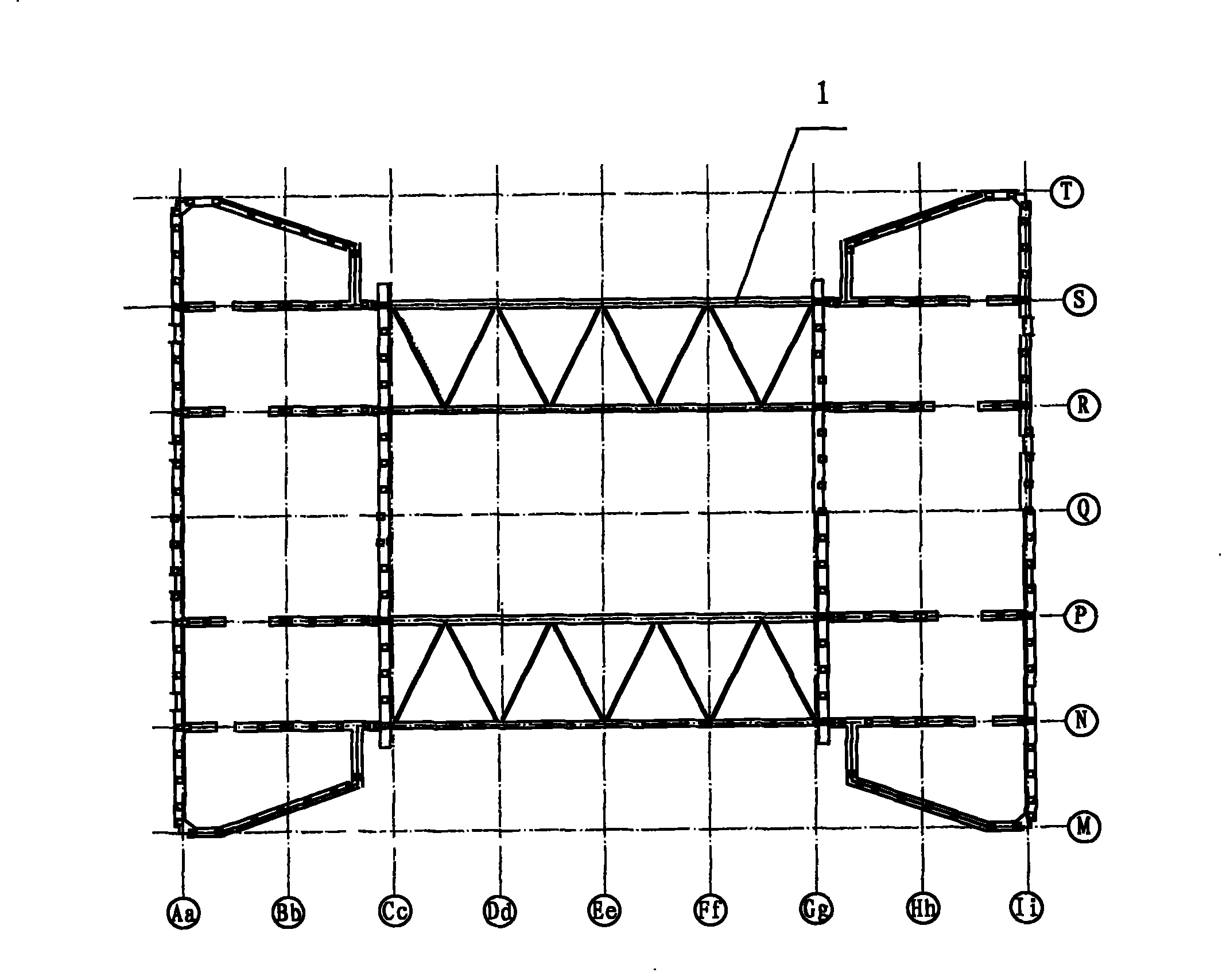

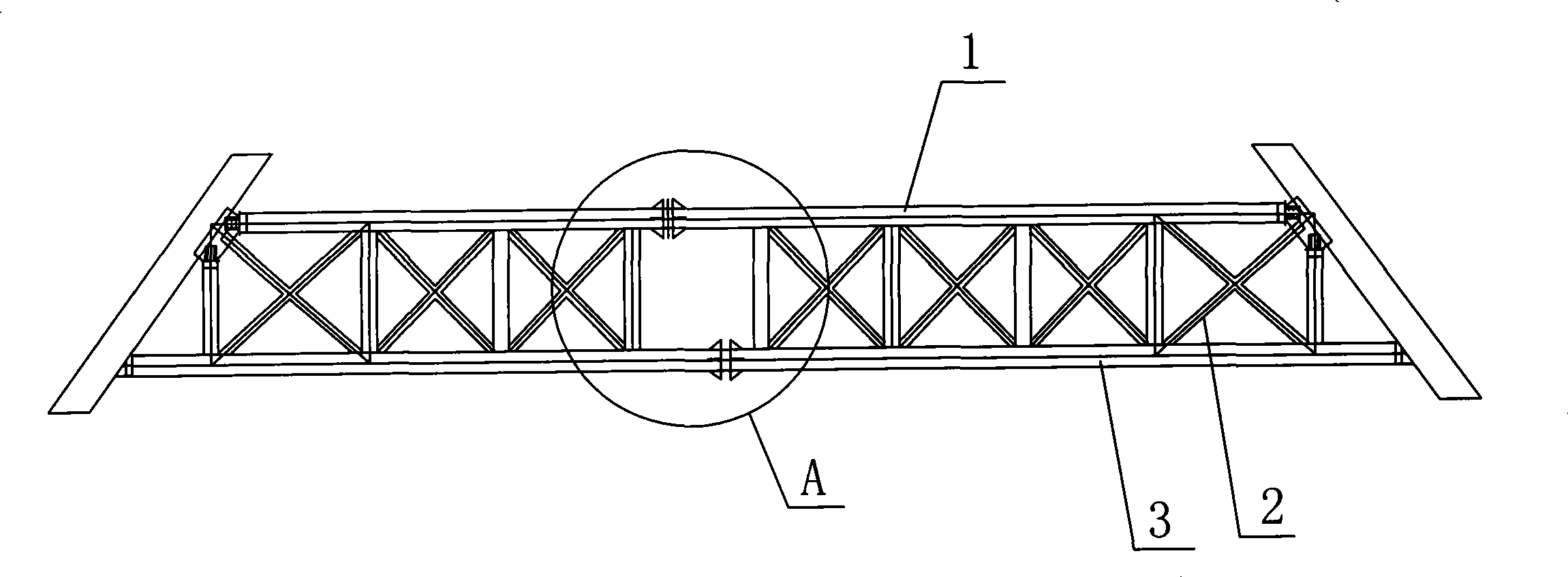

[0039] Such as figure 1 , figure 2 As shown, the temporary support truss constructed by the present invention is a horizontal truss and it consists of an upper chord 1, a lower chord 3, and a plurality of webs 2 installed between the upper chord 1 and the lower chord 3. The temporary support truss The quantity is one or more and its upper chord 1 and lower chord 3 are all made of steel pipes.

[0040] In this embodiment, what is unloaded horizontally is the four reinforced steel pipe connection trusses added in the four directions of the S, R, P, and N axes at an elevation of 79-84 meters between the two hands during the construction of the Heshi stupa of Famen Temple. 4 temporary support trusses. The temporary support truss is supported by two steel pipe lattice columns, and the elevation of the upper chord 1 of each temporary support truss is 84 meters, the elevation of the lower chord 3 is 79 meters, and the elevation of the bottom of the supporting steel column is 54 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com