Protective type machine tool screw rod stroke stopper mechanism

A stroke stopper and protective technology, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problem of limiting the flexibility and versatility of travel stopper equipment, the inability to adjust the operating state of machine tools, and the travel stopper Reduced protection ability and other problems, to achieve the effect of convenient installation, positioning and operation, improved flexibility and convenience, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

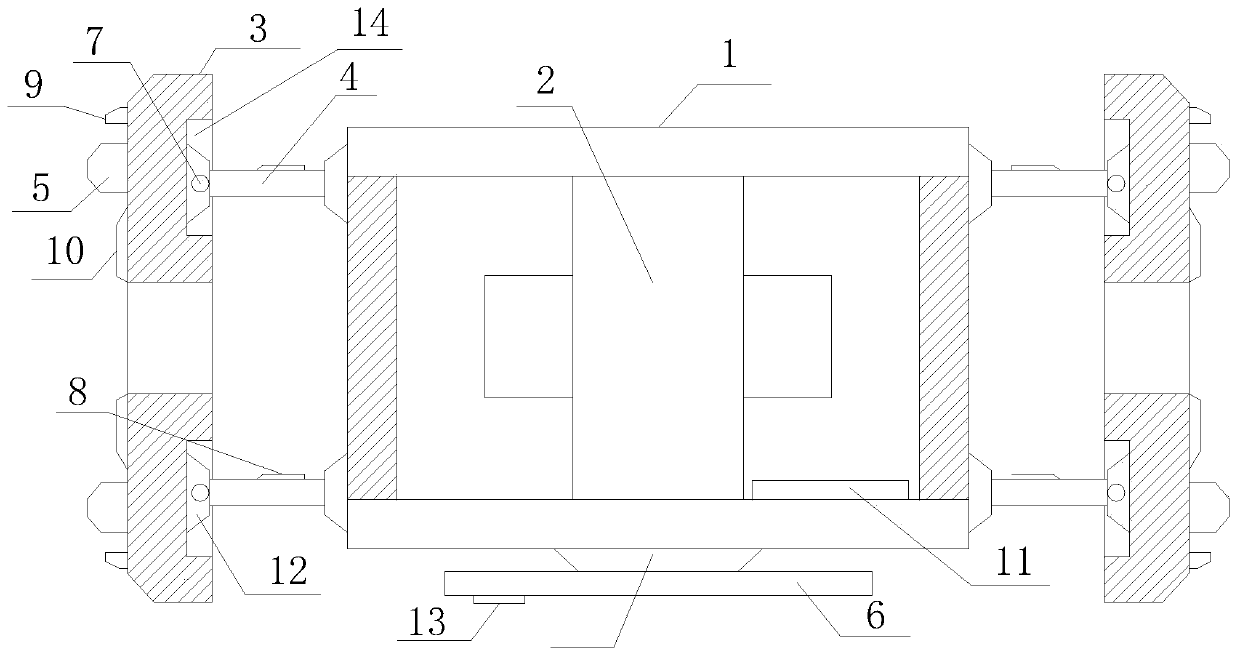

[0016] like figure 1 The above-mentioned protective machine tool screw travel block mechanism includes a bearing base 1, a nut seat 2, a baffle plate 3, an electric folding rod 4, an elastic pad 5, a driving guide rail 6, a pressure sensor 7, an inclination sensor 8, Proximity sensor 9, ranging sensor 10 and control circuit 11, wherein the bearing base 1 has a hollow columnar structure, the nut seat 2 is embedded in the bearing base 1 and coaxially distributed with the bearing base 1, and at least one driving guide rail 6 is provided on the side surface of the bearing base 1 , there are at least two baffles 3, which are symmetrically distributed on the front end surface and the rear end surface of the bearing base 1 with the axis of the bearing ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com