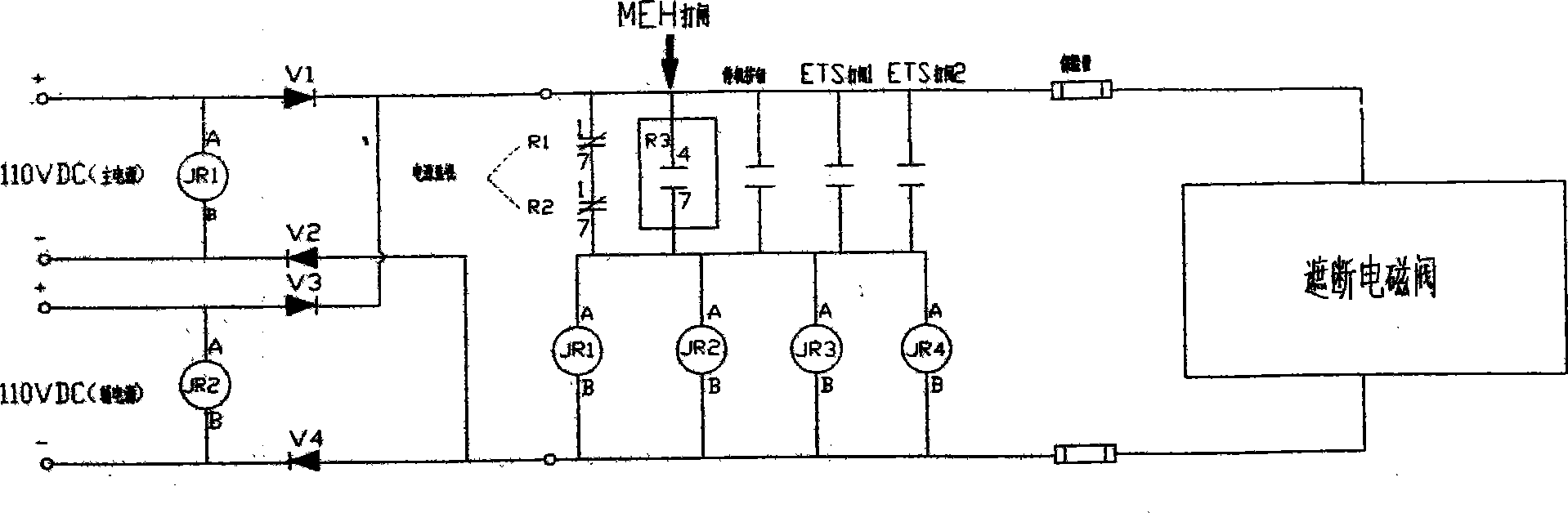

Full fault automatic stop relay protection circuit of steam turbine digital electrohydraulic control system master control modular unit

A technology of automatic shutdown and relay protection, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve problems such as safety accidents, self-resetting of solenoid valves, abnormal re-activation of steam turbines, etc., to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

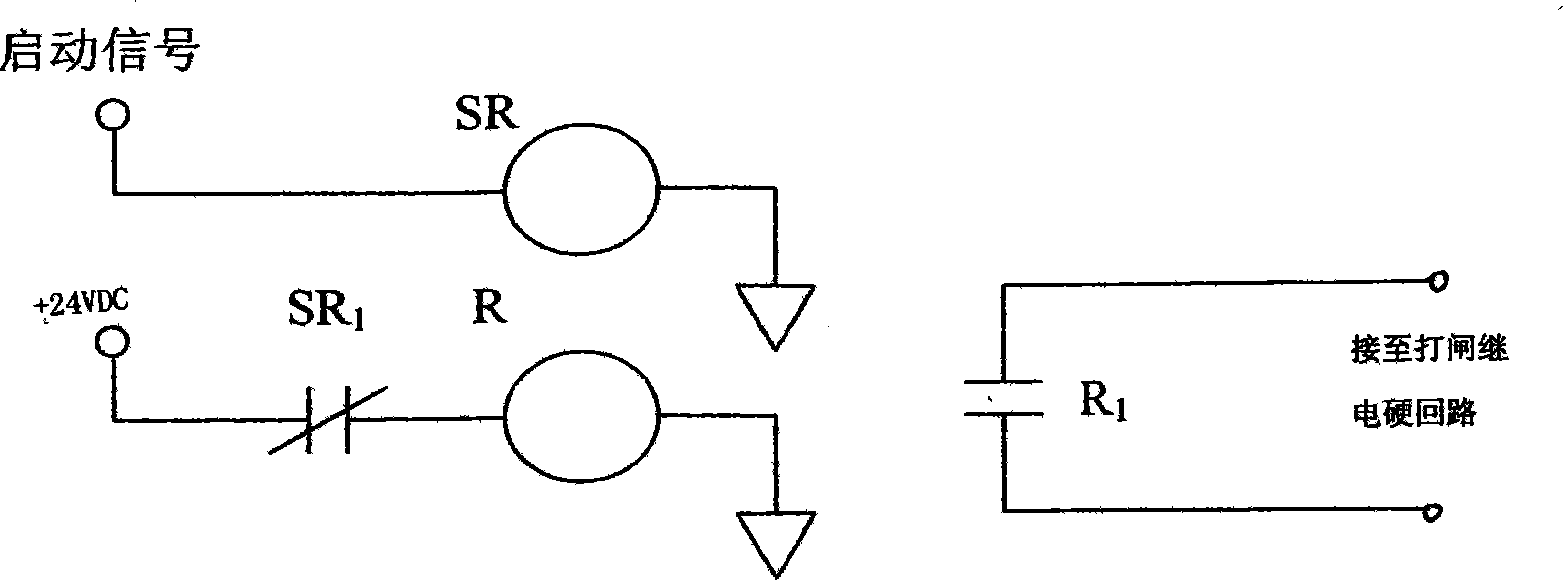

[0019] see figure 2 , Image 6 : The main control module of this MEH control system is fully fault automatic shutdown relay protection circuit is connected by a time relay SR and a conventional relay R according to "AND" logic.

[0020] Its working principle is: the configuration logic of the engineer station of the MEH control system sends two pulse signals, which are respectively output through one channel of the two output modules (dry contact output), and the two pulse signals are respectively connected to the The start signal input terminal of the time relay SR. When the main control unit (DPU) of the MEH control system is working normally, the pulse signal will also be continuously sent out. At this time, the wire package of the time relay SR is always charged, and its normally closed contact SR 1 In the disconnected state, the conventional relay R does not act. If the main control module of the MEH control system fails completely, the pulse signal will disappear im...

Embodiment 2

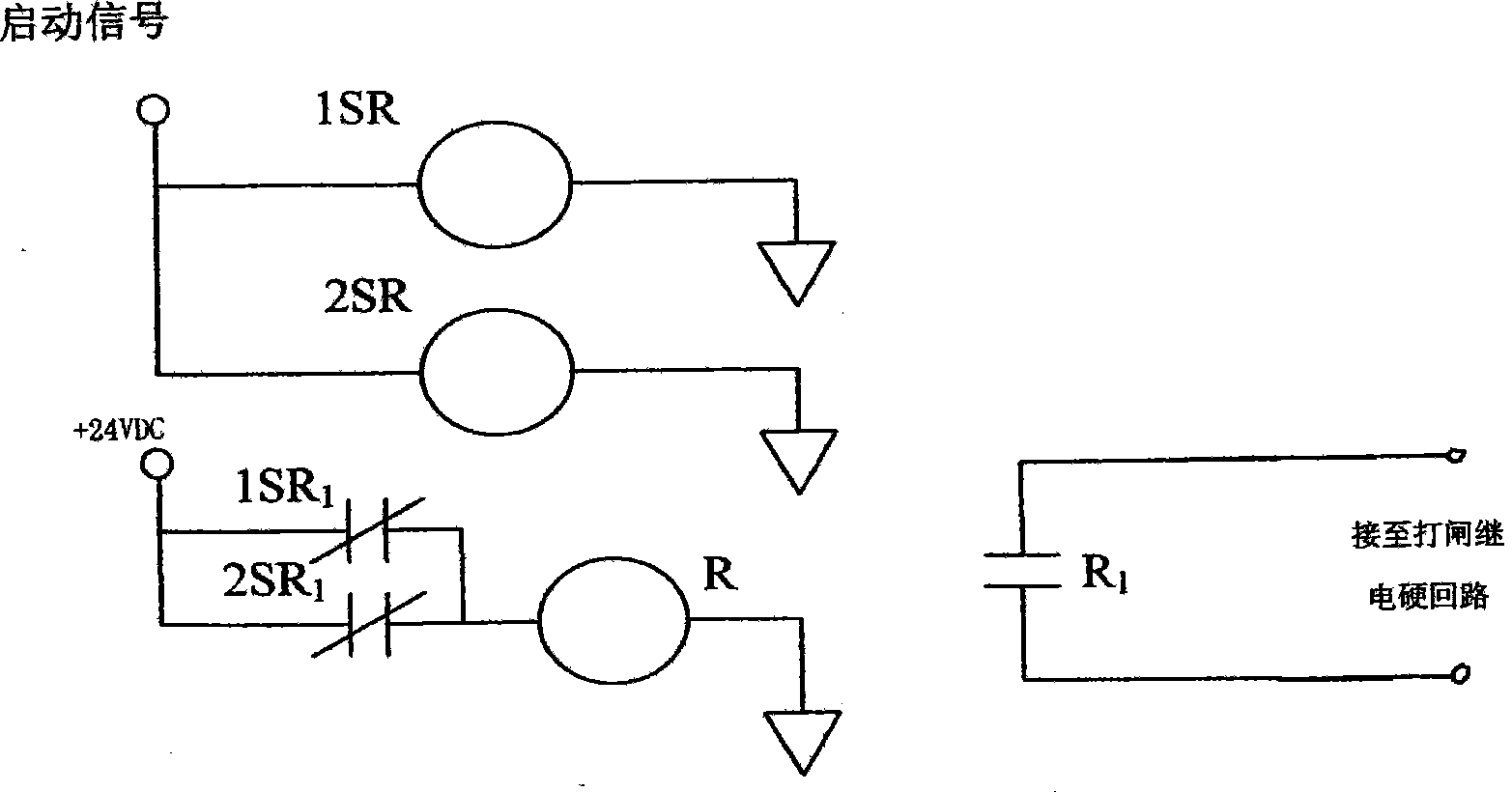

[0022] see image 3 , Image 6 : The main control module of this MEH control system is fully fault automatic shutdown relay protection circuit is connected by two time relays 1SR, 2 SR according to "OR" logic, and then connected with a conventional relay R according to "AND" logic.

[0023] Its working principle is: the configuration logic of the engineer station of the MEH control system sends two pulse signals, which are respectively output through one channel of the two output modules (dry contact output), and the two pulse signals are respectively connected to the The start signal input terminal of time relays 1SR and 2 SR. When the main control unit (DPU) of the MEH control system is working normally, the pulse signal will also be continuously sent out. At this time, the wire packages of the time relays 1SR and 2 SR are always charged, and their normally closed contact 1SR 1 , 2 SR 1 In the disconnected state, the conventional relay R does not act. If the main contro...

Embodiment 3

[0025] see Figure 4 , Image 6 : The main control module of this MEH control system is fully fault automatic shutdown relay protection circuit by two time relays 1SR, 2 SR connected by "AND" logic, and then connected with a conventional relay R by "AND" logic.

[0026] Its working principle is: the configuration logic of the engineer station of the MEH control system sends two pulse signals, which are respectively output through one channel of the two output modules (dry contact output), and the two pulse signals are respectively connected to the The start signal input terminal of time relays 1SR and 2 SR. When the main control unit (DPU) of the MEH control system is working normally, the pulse signal will also be continuously sent out. At this time, the wire packages of the time relays 1SR and 2 SR are always charged, and their normally closed contact 1SR 1 , 2 SR 1 In the disconnected state, the conventional relay R does not act. If the main control module of the MEH c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com