Lubricating grease charging machine

A technology of injector and lubricating grease, applied in the direction of manual lubricant supply, engine lubrication, engine components, etc., can solve the problems of low efficiency, uneven greasing, laborious and other problems, and achieve convenient use, uniform greasing, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

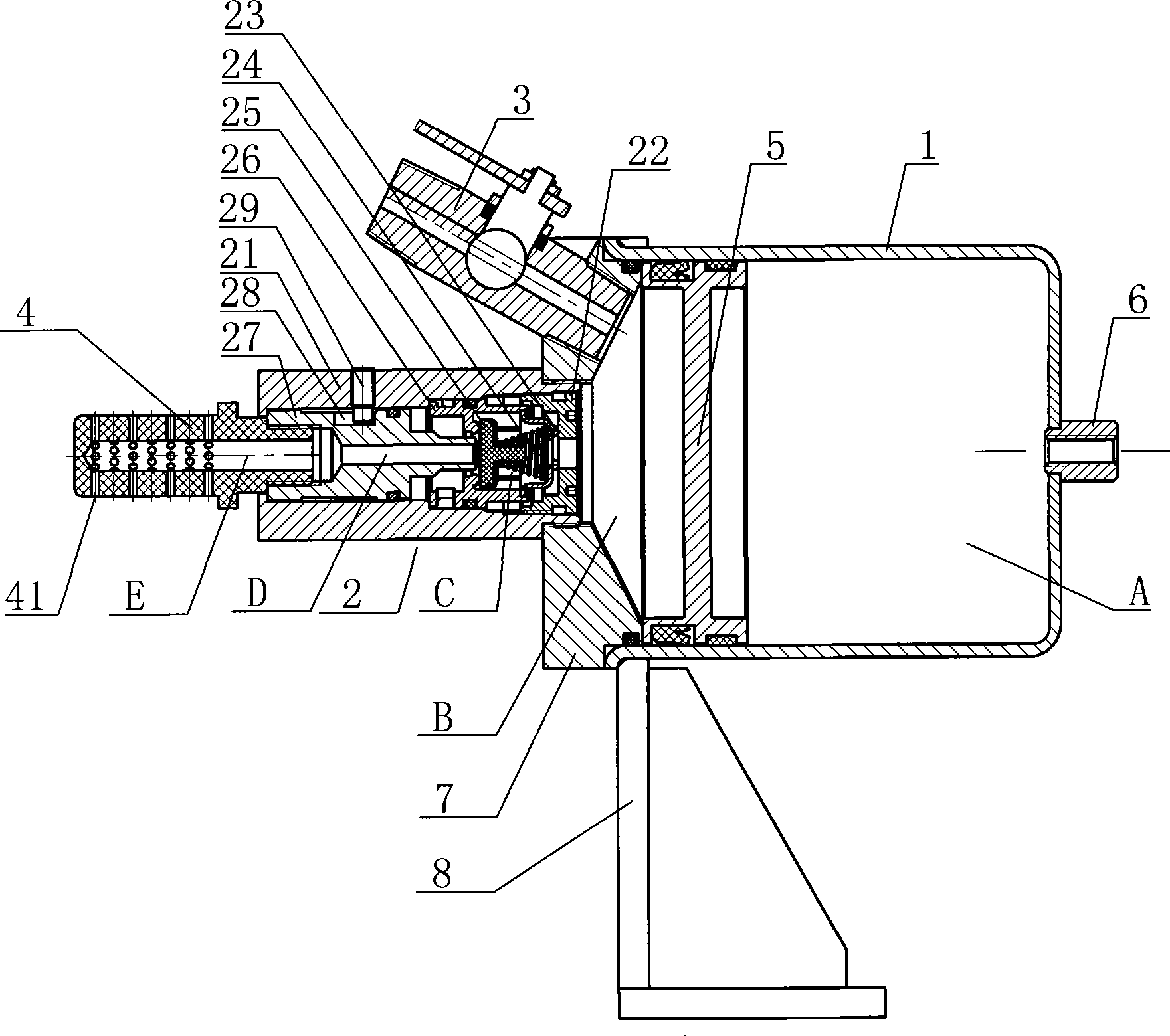

[0014] figure 1 Among them, a grease injector includes a cylinder 1, a one-way valve assembly 2, an oil flushing valve 3, and an extrusion head 4. A piston 5 is built in the cylinder 1, and the piston 5 divides the cylinder 1 into an air intake chamber. A and the oil storage chamber B, the end of the air intake chamber B is provided with an inflatable nozzle 6, and the inflatable nozzle 6 is a threaded joint welded on the end A of the air intake chamber of the cylinder barrel 1. The B end of the oil storage chamber of the cylinder barrel 1 is bolted and fixed with an upper cover plate 7, and the upper cover plate 7 is screwed with the check valve assembly 2 and the oil flushing valve 3 respectively. The extrusion head 4 is provided with an oil outlet 41 , the end of the check valve assembly 2 is connected to the extrusion head 4 , and the oil outlet 41 of the extrusion head 4 communicates with the outlet of the check valve assembly 2 . A support frame 8 is fixed under the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com