LCD module and encapsulation method thereof

The technology of a liquid crystal display module and a liquid crystal screen is applied in the direction of optics, instruments, printed circuits connected with non-printed electrical components, etc., which can solve the problems that it is difficult to ensure the correct position of light-emitting diodes 4, so as to ensure brightness and uniformity, and improve Assembly quality, to ensure the effect of precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

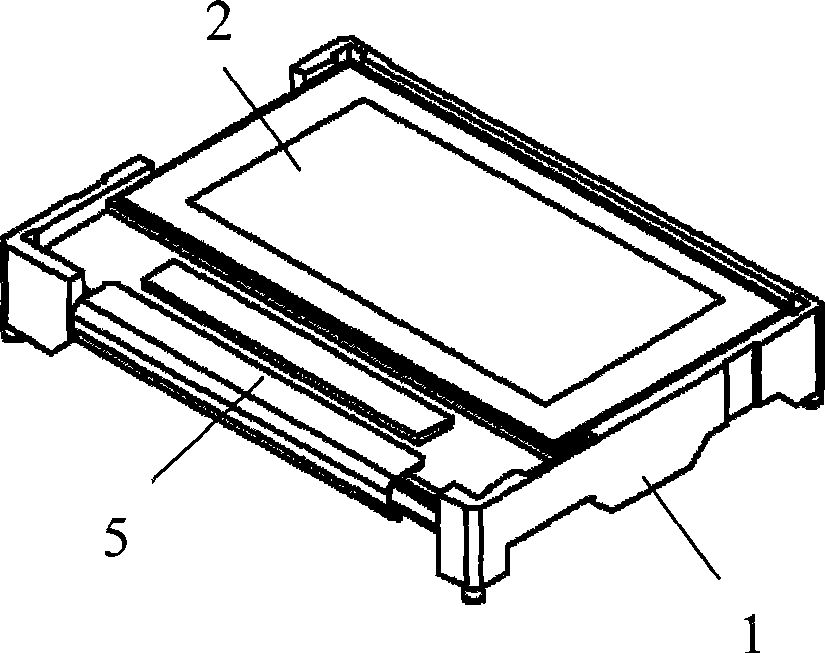

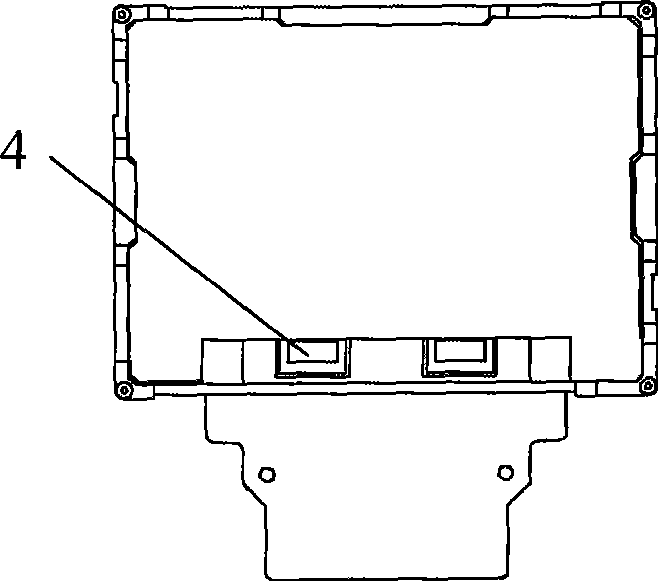

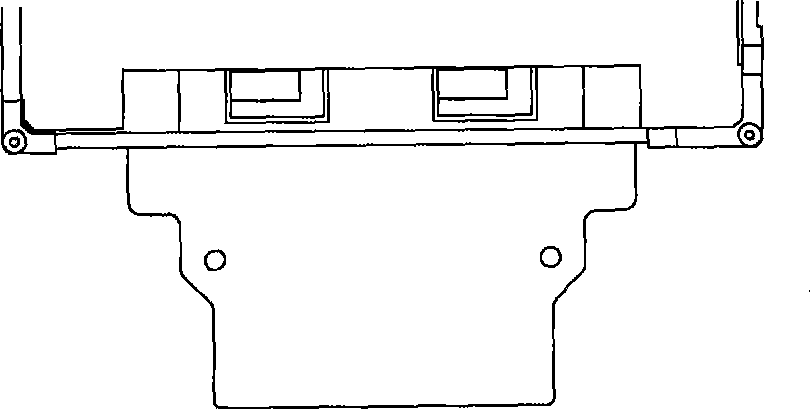

[0017] See Figure 7 , Figure 8 , Figure 9 , a liquid crystal display module includes a backlight module 1, a liquid crystal screen 2, a light emitting diode 4 and a flexible printed circuit board 5, the flexible printed circuit board 5 is connected to the liquid crystal screen 2, the liquid crystal screen 2 is assembled in the backlight module 1, and the flexible printed circuit board The circuit board 5 includes a connection area 6 connected to the liquid crystal screen 2 by thermocompression, a wiring area 7 and a light-emitting diode installation area 8, and the flexible printed circuit board 5 and the liquid crystal screen 2 are thermocompressed in the thermocompression connection area 6, and the flexible printed circuit The board 5 separates the wiring area 7 from the light emitting diode installation area 8 by partial cutting, the partial cutting cut 9 reaches the edge of the liquid crystal screen 2, the light emitting diode 4 is installed on the light emitting diode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com